Pressure infiltration preparing method for metal matrix composite material

A composite material and metal-based technology, applied in the field of composite material preparation, can solve problems such as high cost and achieve good material consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

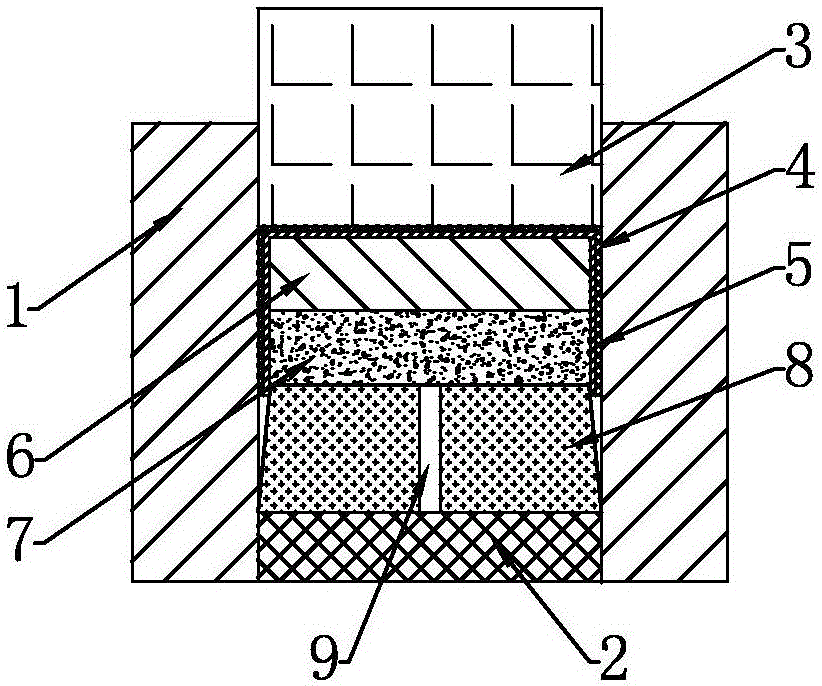

[0028] see figure 1 , in this embodiment, the high-melting-point ceramic component powder 7 and the low-melting-point metal component 6 of the metal matrix composite material are respectively made of silicon powder and aluminum to prepare AlSi60, and the theoretical volume ratio of silicon powder and aluminum is 6:4 , its preparation method is as follows:

[0029] 1) Take the silicon powder required for the preparation of materials, and obtain the silicon powder with a bulk density of 60% by proportioning the particles. For standby, take an aluminum block, wherein the materials of silicon powder and aluminum are taken according to the weight ratio of 1.07:1, Graphite paper 5 is lined inside the wrapping 4, and the aluminum block and silicon powder are sequentially loaded into the wrapping 4 with one end closed; after being loaded into the wrapping 4, the silicon powder is close to the opening end of the wrapping 4;

[0030] 2) use a sealing head 8 to close the open end of the...

Embodiment 2

[0036] see figure 1 , in this embodiment, the high-melting-point ceramic component powder 7 and the low-melting-point metal component 6 of the metal matrix composite are prepared from silicon carbide powder and aluminum, respectively, to prepare AlSiC70, and the material theoretical volume ratio of silicon carbide powder and aluminum is 7 : 3, its preparation method is as follows:

[0037] 1) Take the silicon carbide powder required for the preparation of materials, and obtain the silicon carbide powder with a bulk density of 70% through the particle ratio. For standby, take an aluminum block, wherein the silicon carbide powder and aluminum materials are taken according to the weight ratio of 2.3:1 Graphite paper 5 is lined inside the package 4, and the aluminum block and silicon carbide powder are sequentially packed into the package 4 with one end closed; after being loaded into the package 4, the silicon carbide powder is close to the open end of the package 4;

[0038] 2)...

Embodiment 3

[0044] see figure 1 , in this embodiment, the high-melting-point ceramic component powder 7 and the low-melting-point metal component 6 of the metal matrix composite material are respectively prepared from silicon carbide powder and magnesium to prepare MgSiC65, and the material theoretical volume ratio of silicon carbide powder and aluminum is 6.5 : 3.5, its preparation method is as follows:

[0045] 1) Take the silicon carbide powder required for the preparation of materials, and obtain a silicon carbide powder with a bulk density of 65% through the particle ratio. For standby, take a piece of magnesium block, wherein the material weight of silicon carbide powder and magnesium block is taken according to 2.84:1 Material; graphite paper 5 is lined inside the bag 4, and the magnesium block and silicon carbide powder are sequentially packed into the bag 4 with one end closed; after the bag 4 is loaded, the silicon carbide powder is close to the open end of the bag 4;

[0046] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com