Adhesive specially used for bamboo plywood

A technology of bamboo plywood and glue, applied in the field of plywood, can solve the problems of easy cracking, water resistance, poor adhesiveness of glue, etc., achieve high bonding strength, good dispersion, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

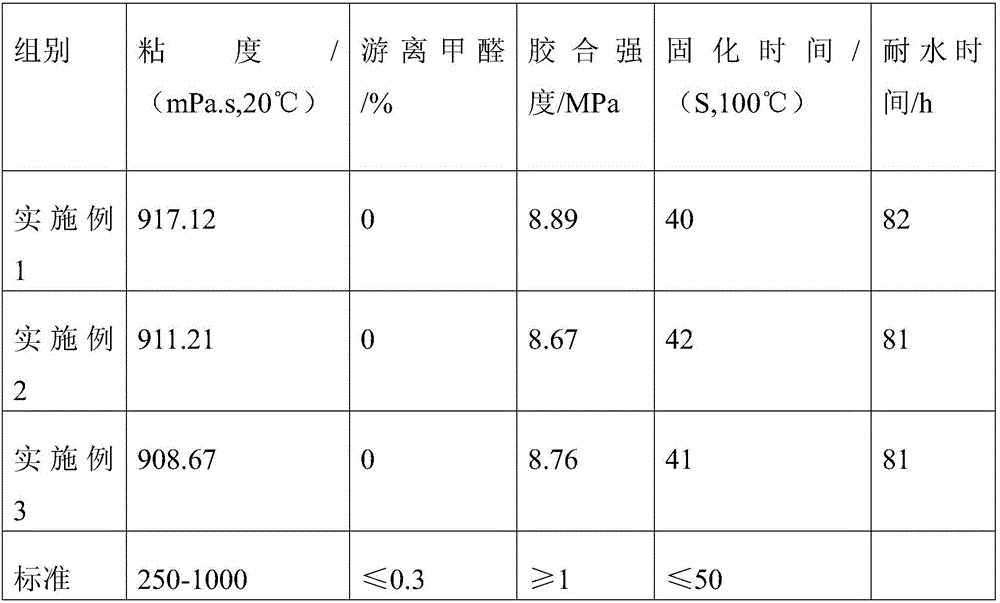

Examples

Embodiment 1

[0015] A special adhesive for bamboo plywood, mainly made of the following raw materials in parts by weight: 17 parts of vegetable glue, 11 parts of borax, 8 parts of paraben, 12 parts of urea, 2 parts of formaldehyde, and melamine rubber powder 3 parts, 11 parts of lignin, 8 parts of zinc naphthenate, 7 parts of dodecenyl dicyclohexylamine, 9 parts of ethyl acetate, 11 parts of acid anhydride, 4 parts of polyvinyl alcohol and 6 parts of sodium pyrophosphate.

[0016] The vegetable gum is arrowroot starch.

[0017] A kind of preparation method of the adhesive glue special for bamboo plywood, comprises the following steps:

[0018] (1) Mix formaldehyde and polyvinyl alcohol, adjust the pH value to 7.5, then add urea, raise the temperature to 53°C for 30 minutes, then raise the temperature to 90°C, add melamine rubber powder and react for 50 minutes to obtain slurry I;

[0019] (2) The concentration of the configuration is 23 degrees Baume, the vegetable glue slurry with a pH v...

Embodiment 2

[0021] A special adhesive for bamboo plywood, mainly made of the following raw materials in parts by weight: 11 parts of plant glue, 14 parts of borax, 6 parts of paraben, 16 parts of urea, 3 parts of formaldehyde, and melamine rubber powder 4 parts, 8 parts of lignin, 12 parts of zinc naphthenate, 4 parts of dodecenyl dicyclohexylamine, 5 parts of ethyl acetate, 7 parts of acid anhydride, 7 parts of polyvinyl alcohol and 1 part of sodium pyrophosphate.

[0022] The vegetable gum is arrowroot starch.

[0023] A kind of preparation method of the adhesive glue special for bamboo plywood, comprises the following steps:

[0024] (1) Mix formaldehyde and polyvinyl alcohol, adjust the pH value to 7, then add urea, raise the temperature to 55°C for 20 minutes, then raise the temperature to 100°C, add melamine rubber powder and react for 30 minutes to obtain slurry I;

[0025] (2) The concentration of the configuration is 20 degrees Baume, the vegetable glue slurry with a pH value of...

Embodiment 3

[0027] A special adhesive for bamboo plywood, mainly made of the following raw materials in parts by weight: 22 parts of plant glue, 6 parts of borax, 11 parts of paraben, 8 parts of urea, 1 part of formaldehyde, and melamine rubber powder 2 parts, 18 parts of lignin, 4 parts of zinc naphthenate, 9 parts of dodecenyl dicyclohexylamine, 14 parts of ethyl acetate, 17 parts of acid anhydride, 3 parts of polyvinyl alcohol and 9 parts of sodium pyrophosphate.

[0028] The vegetable gum is arrowroot starch.

[0029] A kind of preparation method of the adhesive glue special for bamboo plywood, comprises the following steps:

[0030] (1) Mix formaldehyde and polyvinyl alcohol, adjust the pH value to 7.5, then add urea, raise the temperature to 50°C for 40 minutes, then raise the temperature to 85°C, add melamine rubber powder and react for 60 minutes to obtain slurry I;

[0031] (2) The configuration concentration is 25 degrees Baume, and the vegetable glue slurry with a pH value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com