Machining device based on intelligent control motor equipment shell

A technology of electrical equipment and intelligent control, applied in the direction of electromechanical devices, manufacturing motor generators, manufacturing tools, etc., can solve the problems of incapable parts grinding, the impact of parts grinding accuracy, scratching the operator, etc., to improve the grinding accuracy and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

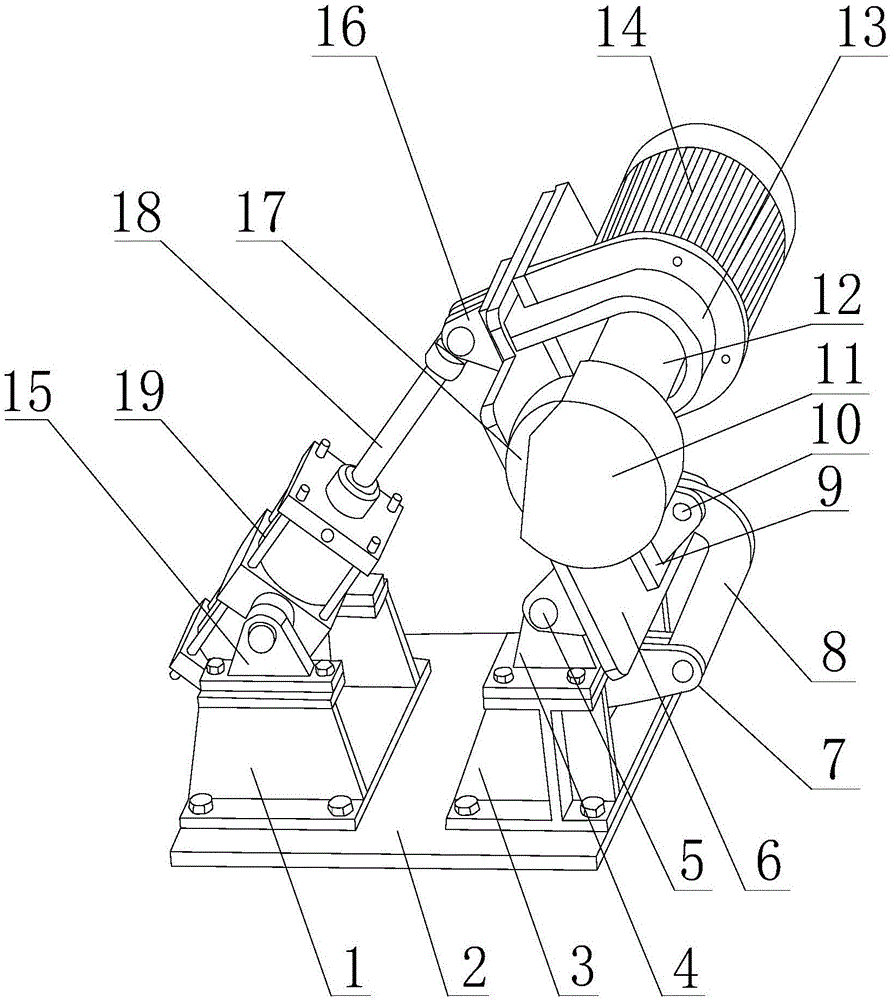

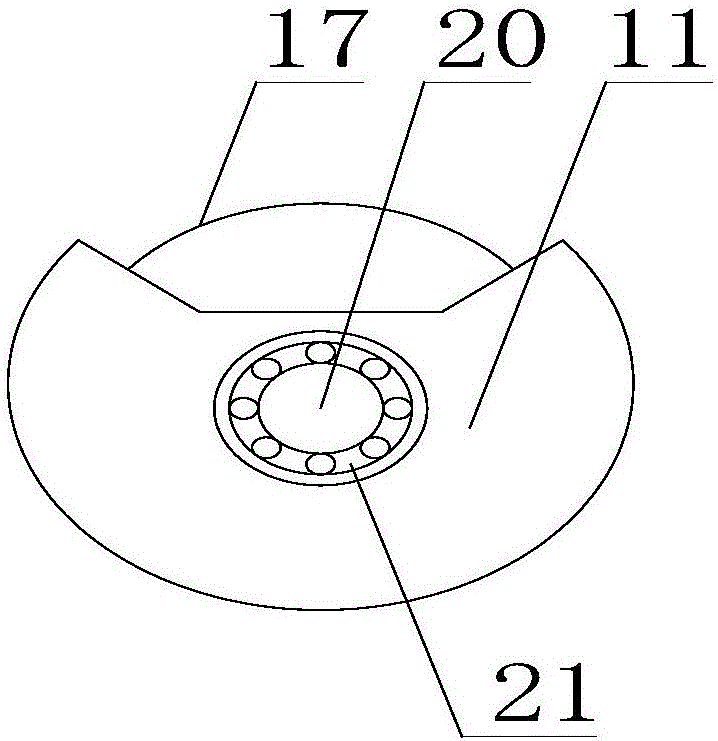

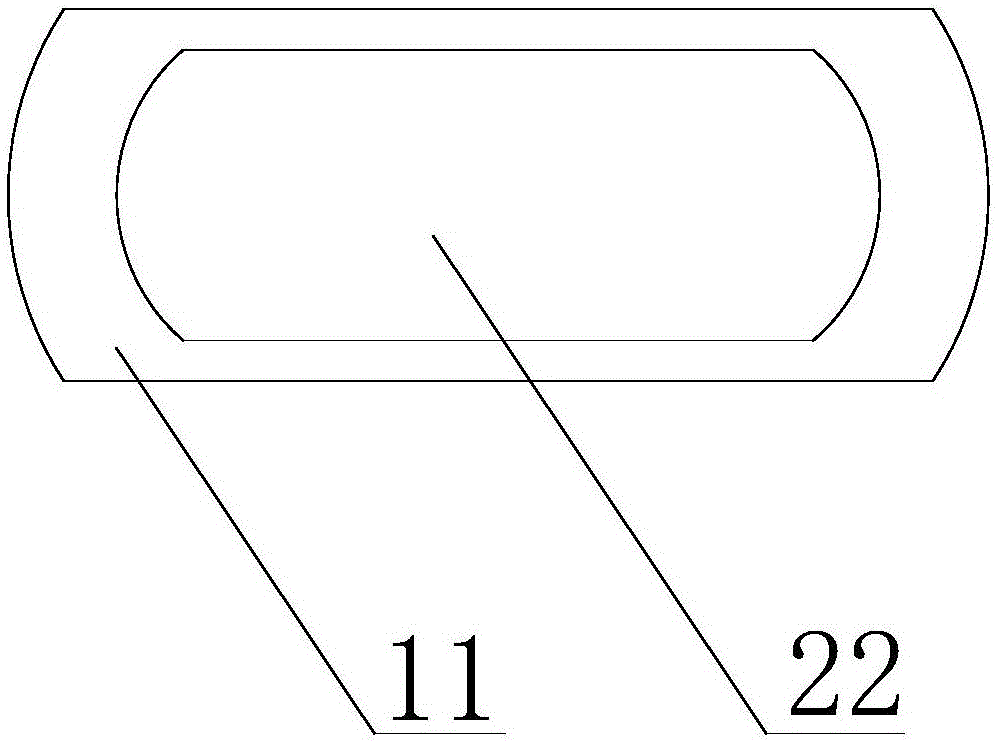

[0024] Such as Figure 1 to Figure 3 As shown, the present invention is based on the processing device of the intelligent control motor equipment shell, including a base 2, a motor 14 and a grinding head 17 connected to the output shaft 12 of the motor 14, the base 2 is a rectangular structure, and the grinding head 17 is a prior art , metal can be polished, the top of the base 2 is provided with a first fixed platform 1 and a second fixed platform 3, the first fixed platform 1 and the second fixed platform 3 are located on both sides of the axis of the base 2, the first fixed platform The fixed platform 1 is provided with a first supporting platform 15, and the first supporting platform 15 is connected with the through hole screw between the first fixed platform 1. The first supporting platform 15 is provided with a driving mechanism 19, and the driving mechanism 19 is preferably a cylinder, which is convenient Operation, stable work, the drive mechanism 19 includes a drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com