Sodium ion battery negative electrode slurry, preparation method thereof, and negative electrode plate

A technology of sodium ion battery and negative electrode slurry, applied in electrode manufacturing, battery electrode, secondary battery, etc., can solve the problems of battery short circuit, bulging, poor flexibility of the pole piece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

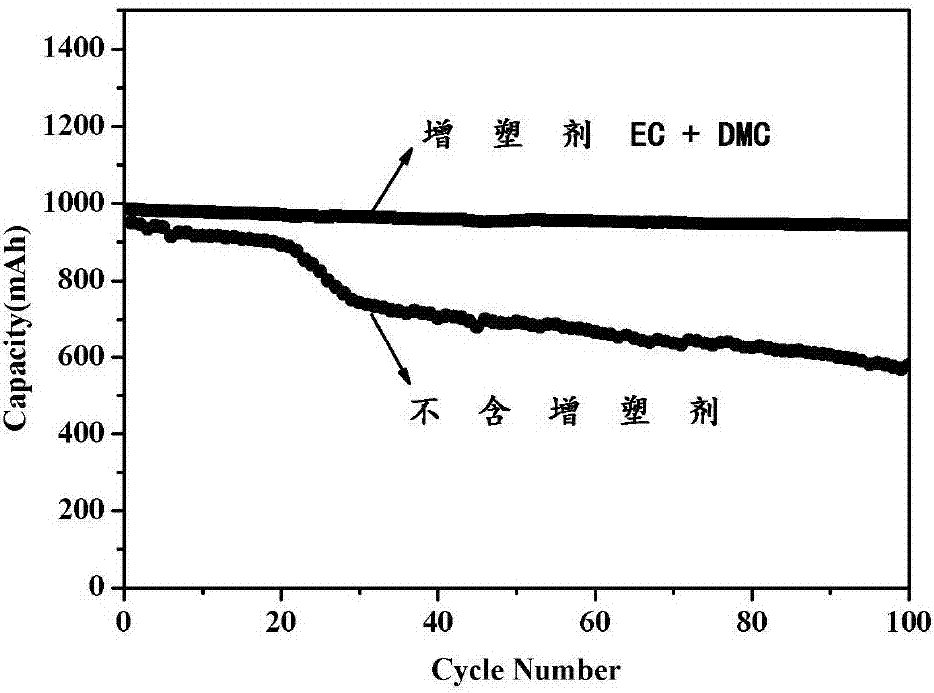

Problems solved by technology

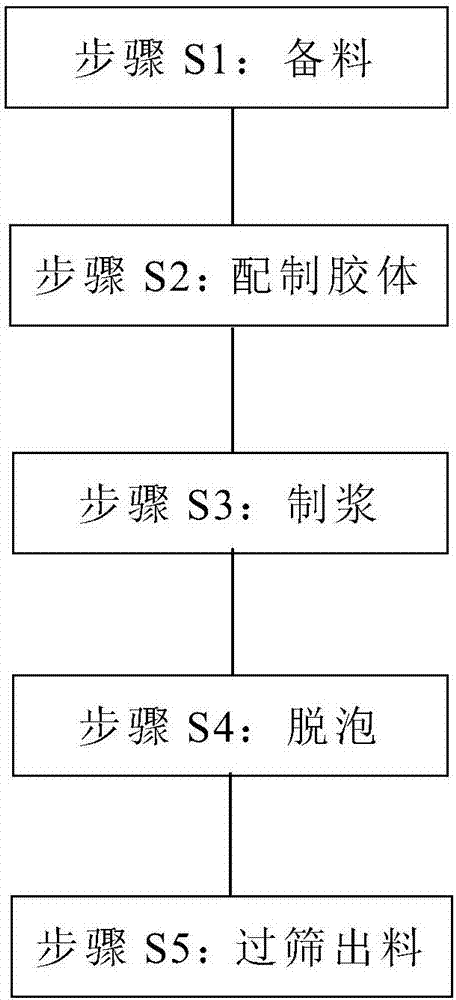

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of negative electrode

[0024] Add 100 parts by weight of solvent deionized water and 3 parts by weight of water-based binder polyacrylonitrile to the stirrer, and stir for 1 hour at 30 revolutions per minute and 3000 revolutions per minute at autorotation; then add 4 parts by weight of conductive agent acetylene black Stir for 2 hours, then add 0.5 parts by weight of plasticizer ethylene carbonate (EC) and stir for 2 hours; finally add 100 parts by weight of negative electrode active material hard carbon and stir for 2 hours, through defoaming, cross a 200 mesh sieve to make the Necessary sodium ion battery negative electrode slurry.

[0025] The negative electrode slurry of the sodium ion battery obtained above was evenly coated on a 20 micron thick aluminum foil by drawing, dried, pressed into sheets, and cut into negative electrode sheets of 45×29 mm, numbered a1.

[0026] (2) Preparation of positive electrode

[0027] 100 parts by weight of the po...

Embodiment 2

[0031] Add 80 parts by weight of solvent deionized water and 3 parts by weight of water-based binder polyacrylic acid to the stirrer, stir for 2 hours at 45 revolutions per minute and 2500 revolutions per minute at rotation; add 4 parts by weight of conductive graphite and stir for 3 hours , then add 0.5 parts by weight of plasticizer ethyl methyl carbonate (EMC) and stir for 1 hour; finally add 100 parts by weight of negative electrode active material hard carbon and stir for 3 hours, through defoaming, cross 150 mesh sieves, and make the required Sodium ion battery negative electrode slurry.

[0032] The negative electrode slurry of the sodium ion battery obtained above was uniformly coated on a 12 micron thick aluminum foil by drawing, dried, pressed into sheets, and cut into negative electrode sheets of 45×29 mm, numbered a2.

[0033] The same method and steps as in Example 1 were used to prepare the positive electrode and the battery to obtain battery A2.

Embodiment 3

[0035] Add 60 parts by weight of solvent deionized water, 3 parts by weight of water-based binder polyacrylic acid to the stirrer, stir for 2 hours with 30 revolutions per minute of revolution and 3500 revolutions per minute of rotation; then add 3 parts by weight of conductive agent carbon nanotube Stir for 2 hours, then add 1 weight part of plasticizer methyl acetate (MA) and stir for 1 hour; finally add 100 weight parts of negative electrode active material hard carbon and stir for 3 hours, through defoaming, cross a 100 mesh sieve to make the Necessary sodium ion battery negative electrode slurry.

[0036] The negative electrode slurry of the sodium ion battery obtained above was evenly coated on a 12 micron thick aluminum foil by drawing, dried, pressed into sheets, and cut into negative electrode sheets of 45×29 mm, numbered a3.

[0037] The same method and steps as in Example 1 were used to prepare the positive electrode and the battery to obtain battery A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com