Improved polymer phase-based 1-3 type piezoelectric composite material and preparation method therefor

A piezoelectric composite material and polymer technology, which can be used in the material selection of piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials, which can solve the production process. Complexity, poor mechanical stability and other problems, to achieve the effect of significant performance improvement, high electromechanical conversion efficiency, and improved electromechanical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below through specific embodiments and accompanying drawings.

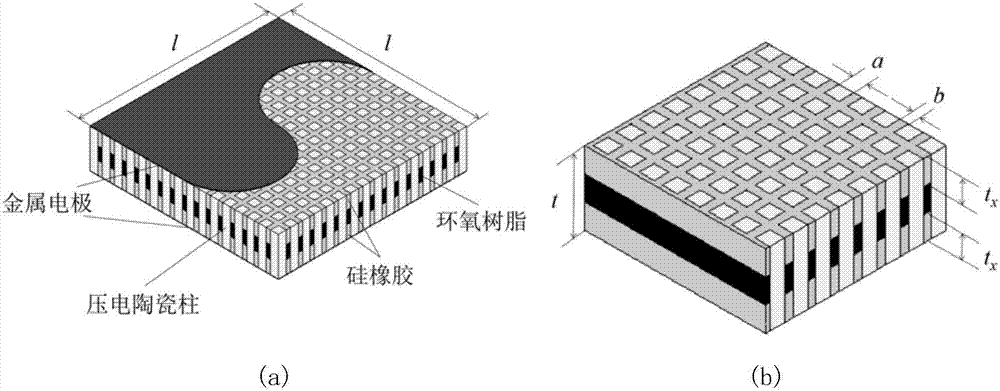

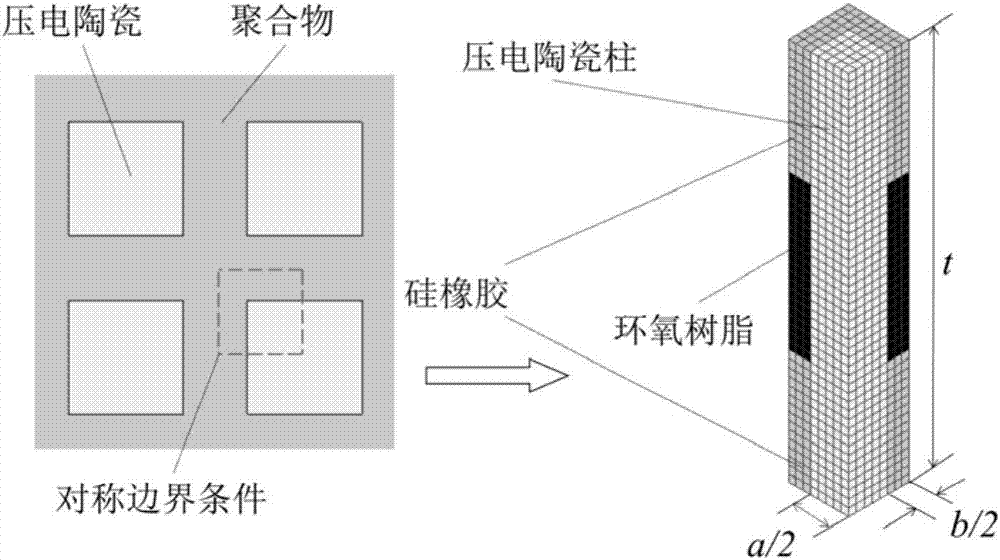

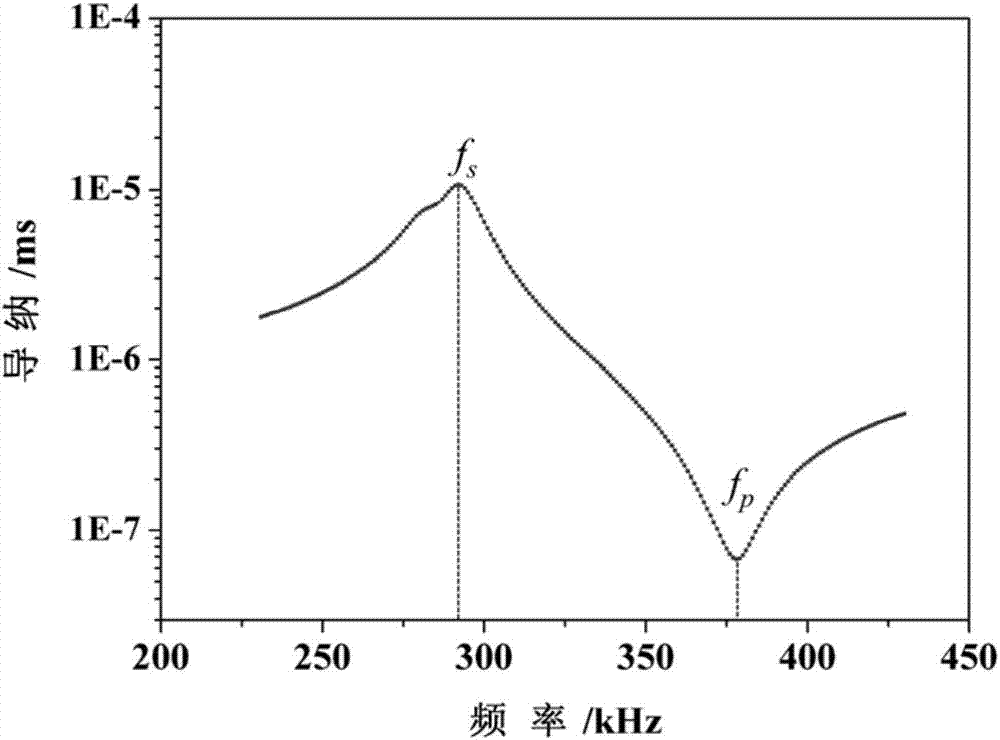

[0038] The improved 1-3 type piezoelectric composite material of this embodiment improves the polymer phase material by adopting a sandwich structure composed of epoxy resin and silicone rubber, so as to reduce the 1-3 type piezoelectric composite material. The influence of the polymer relative to the vibration of the piezoelectric phase, and the application of finite element simulation and experimental methods to analyze the electromechanical properties of this new piezoelectric composite material.

[0039] 1. Structure of Type 1-3 Piezoelectric Composites with Improved Polymer Phase

[0040] figure 1 Schematic diagram of the structure of the 1-3 type piezoelectric composite material for improving the polymer phase, which consists of periodically arranged piezoelectric ceramic column arrays and a polymer phase with a sandwich structure. The polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com