Stainless steel cold rolling sludge recovery processing method

A technology for recycling and processing stainless steel, applied in the improvement of process efficiency, electric furnaces, furnaces, etc., can solve the problems of serious secondary pollution, noise pollution, high cost, etc., and achieve the effect of low processing cost, low investment and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

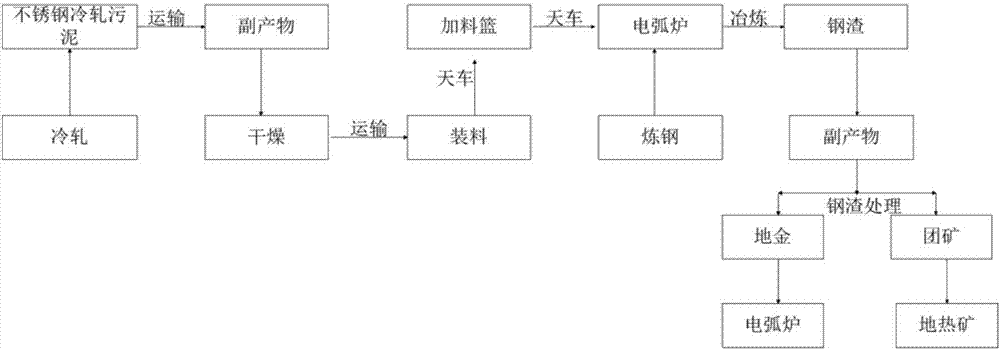

[0040] This embodiment provides a method for reclaiming and treating stainless steel cold rolling sludge, and its technological process is as follows figure 1 As shown, it specifically includes the following steps:

[0041] The sludge generated by the cold rolling plant (the composition is shown in Table 1) is transported by truck to the sludge warehouse of the by-product treatment plant. The storage capacity of the warehouse is about 1,500 tons (the by-product plant has drying equipment and a complete dust removal system);

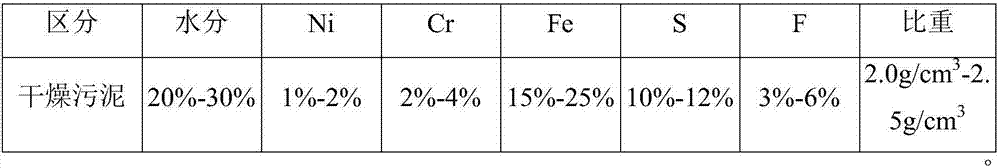

[0042] Table 1

[0043] distinguish

Ni

Cr

Fe

S

F

proportion

sludge

55%

1.1%

2%

18%

10%

2.5%

1.5g / cm 3

[0044] The wet sludge is processed by drying equipment. The composition of the dried cold-rolled sludge is shown in Table 2. It reaches the required moisture target, and the water content is 20wt%-30wt%. In order to reduce the occurrence of dust during the transportation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com