Method for preparing foam glass with adjustable micrometer-level air pore structure by using waste glass as raw material

A foam glass, micron-scale technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of foam glass cell wall thickness, increased process complexity, and high bulk density of foam glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation process is as follows:

[0040] (1) Grind waste flat glass with a dry ball mill and pass through a 200-mesh sieve.

[0041] (2) Add water to the sieved waste glass powder to form a water-based slurry with a solid phase content of 20 wt%, and then use a planetary ball mill for 14 hours.

[0042] (3) The average particle size of the glass powder after planetary ball milling is reduced to 0.7 μm, and 0.40 wt % propyl mantholate and 0.05 wt % sodium cetyl sulfate are added to the slurry after ball milling.

[0043] (4) Stir the slurry after adding the surfactant evenly, then adjust the pH to 7.5 with 1 mol / L hydrochloric acid and ammonia water.

[0044] (5) The obtained slurry was mechanically sheared and foamed with a laboratory mechanical mixer, first stirred at a speed of 500 rpm for 5 min, and then stirred at a high speed of 1800 rpm for 10 min.

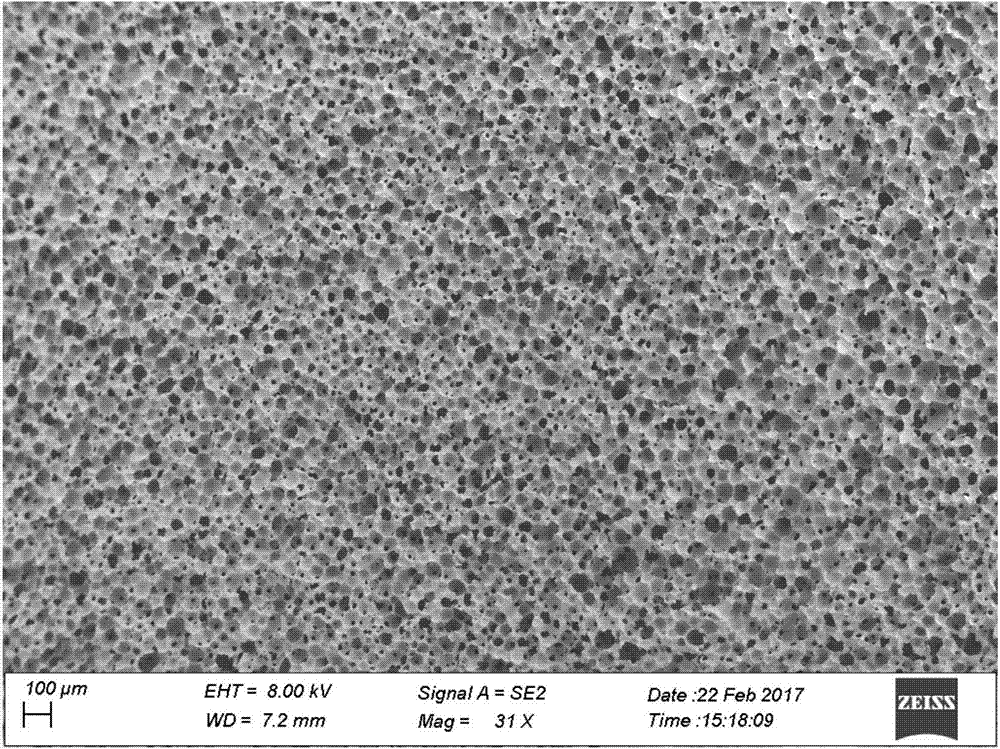

[0045] (6) The foam obtained after mechanical stirring is injection-molded on a gypsum board, demolded aft...

Embodiment 2

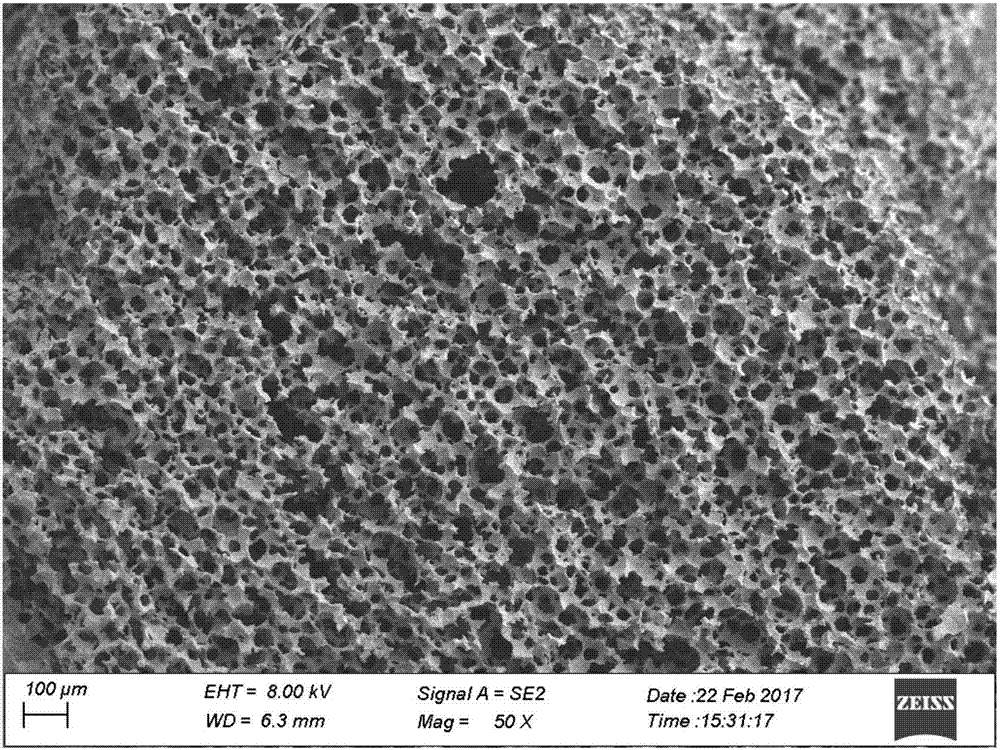

[0047] The preparation process is as follows:

[0048] (1) Grind waste flat glass with a dry ball mill and pass through a 200-mesh sieve.

[0049] (2) the waste glass powder of sieving is added water and is made into the water base slurry that solid phase content is 5wt%, utilizes then

[0050] Planetary ball milling for 16 hours.

[0051](3) The average particle size of the glass powder after planetary ball milling is reduced to 0.5 μm, and 0.30 wt % propyl mantholate and 0.03 wt % sodium cetyl sulfate are added to the slurry after ball milling.

[0052] (4) Stir the slurry after adding the surfactant evenly, then adjust the pH to 7.5 with 1 mol / L hydrochloric acid and ammonia water.

[0053] (5) The obtained slurry was mechanically sheared and foamed with a laboratory mechanical mixer, first stirred at a speed of 700 rpm for 3 minutes, and then stirred at a high speed of 2000 rpm for 15 minutes.

[0054] (6) The foam obtained after mechanical stirring is injection-molded ...

Embodiment 3

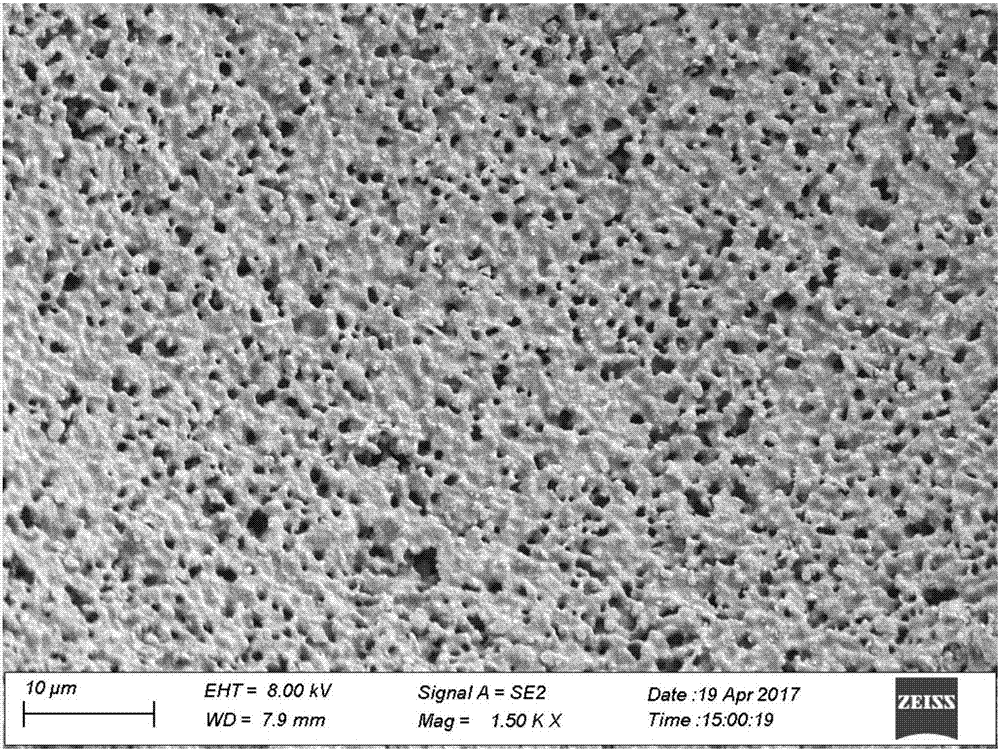

[0057] The preparation process is as follows:

[0058] (1) Grind waste flat glass with a dry ball mill and pass through a 200-mesh sieve.

[0059] (2) Add water to the sieved waste glass powder to form a water-based slurry with a solid phase content of 20 wt%, and then use a planetary ball mill for 10 hours.

[0060] (3) The average particle size of the glass powder after planetary ball milling is reduced to 0.8 μm, and 0.40wt% propyl manganate and 0.04wt% cetyl sodium cetyl sulfate are added to the slurry after the above ball milling

[0061] (4) Stir the slurry after adding the surfactant evenly, then adjust the pH to 7.5 with 1 mol / L hydrochloric acid and ammonia water.

[0062] (5) The obtained slurry was mechanically sheared and foamed with a laboratory mechanical mixer, first stirred at a speed of 300 rpm for 10 min, and then stirred at a high speed of 1500 rpm for 8 min.

[0063] (6) The foam obtained after mechanical stirring is injection-molded on a gypsum board, de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com