Porous metal material having lipophilicity and hydrophobicity and preparation method of same

A porous metal and hydrophobic technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of complex process and long production cycle, and achieve simple preparation process and low production cost Low, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

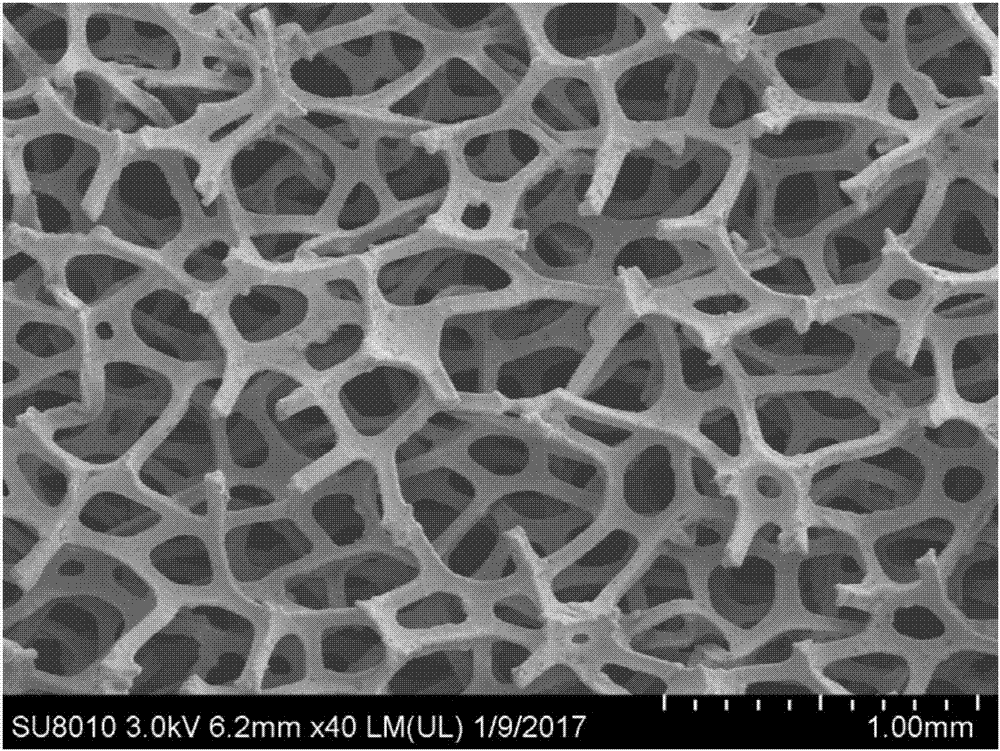

[0032] A kind of porous nickel foam with lipophilicity and hydrophobicity is prepared by the following method:

[0033] 1) Clean and dry the oil and impurities on the surface of nickel foam with a size of 100mm*100mm*50mm and a size of 400 mesh;

[0034] 2) dissolving silicone oil and silicone rubber in toluene to obtain a mixed solution; the mass percent of silicone oil in the mixed solution is 10%, and the mass percent of silicone rubber is 0.05%;

[0035] 3) Soak the nickel foam obtained in step 1) completely in the mixed solution prepared in step 2) for 4 hours at a temperature of 30°C;

[0036] 4) The nickel foam soaked in step 3) was taken out and dried, and then dried and cured at 50° C. for 5 hours under air conditions to obtain a nickel foam material with lipophilicity and hydrophobicity.

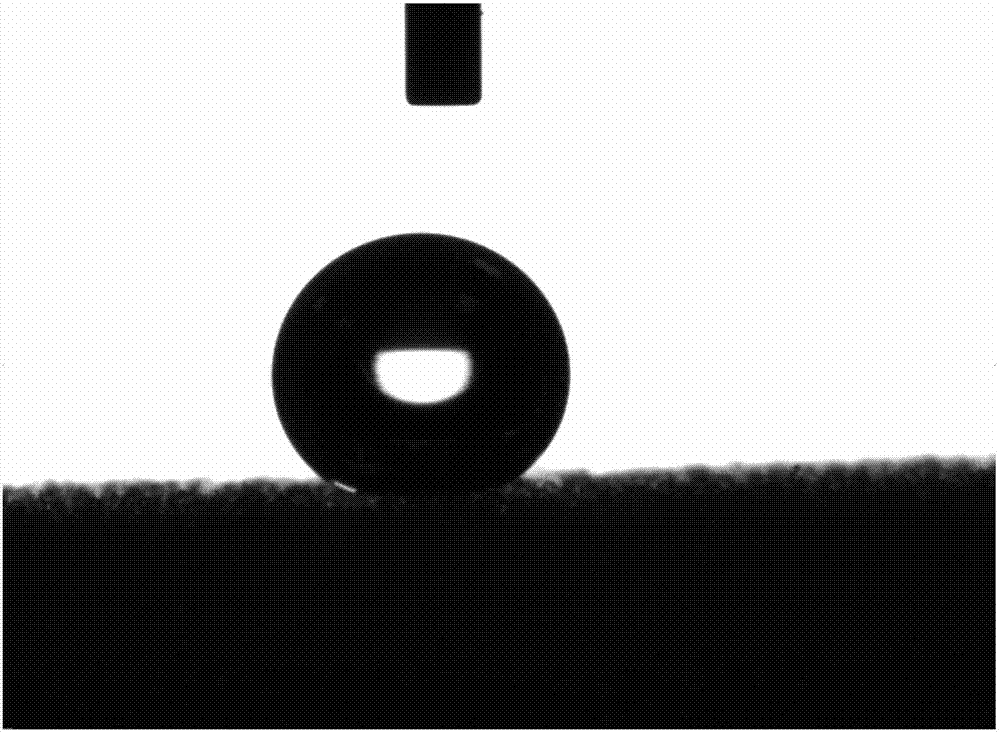

[0037] The lipophilic and hydrophobic foamed nickel material prepared in Example 1 has a contact angle of 155° to water, a contact angle of 0 to No. 0 diesel oil, and an oil absor...

Embodiment 2

[0041] A porous stainless steel wire mesh with lipophilicity and hydrophobicity is prepared by the following method:

[0042] 1) Clean and dry the oil and impurities on the surface of the 80-mesh stainless steel wire mesh;

[0043] 2) dissolving silicone oil and silicone rubber in amyl acetate to obtain a mixed solution; the mass percent of silicone oil in the mixed solution is 30%, and the mass percent of silicone rubber is 0.2%;

[0044] 3) Soak the stainless steel wire mesh obtained in step 1) completely in the mixed solution prepared in step 2) for 24 hours at a temperature of 60°C;

[0045] 4) The stainless steel mesh soaked in step 3) was taken out, and then dried and cured at 80° C. for 20 hours under vacuum conditions to obtain a stainless steel mesh material with lipophilicity and hydrophobicity.

[0046] The lipophilic and hydrophobic stainless steel wire mesh material prepared in Example 2 has a contact angle of 161° to water, and a contact angle of 0 to No. 0 dies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com