Preparation method of composite surface treatment agent and nano-calcium carbonate for high-strength and low-modulus silicone adhesive

A composite surface treatment and nano-calcium carbonate technology, which is applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, and inorganic pigments, can solve the problems of general surface treatment effects, slow carbonization reaction, and insufficient contact. Achieve the effects of reducing particle agglomeration, good surface treatment performance, and reducing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

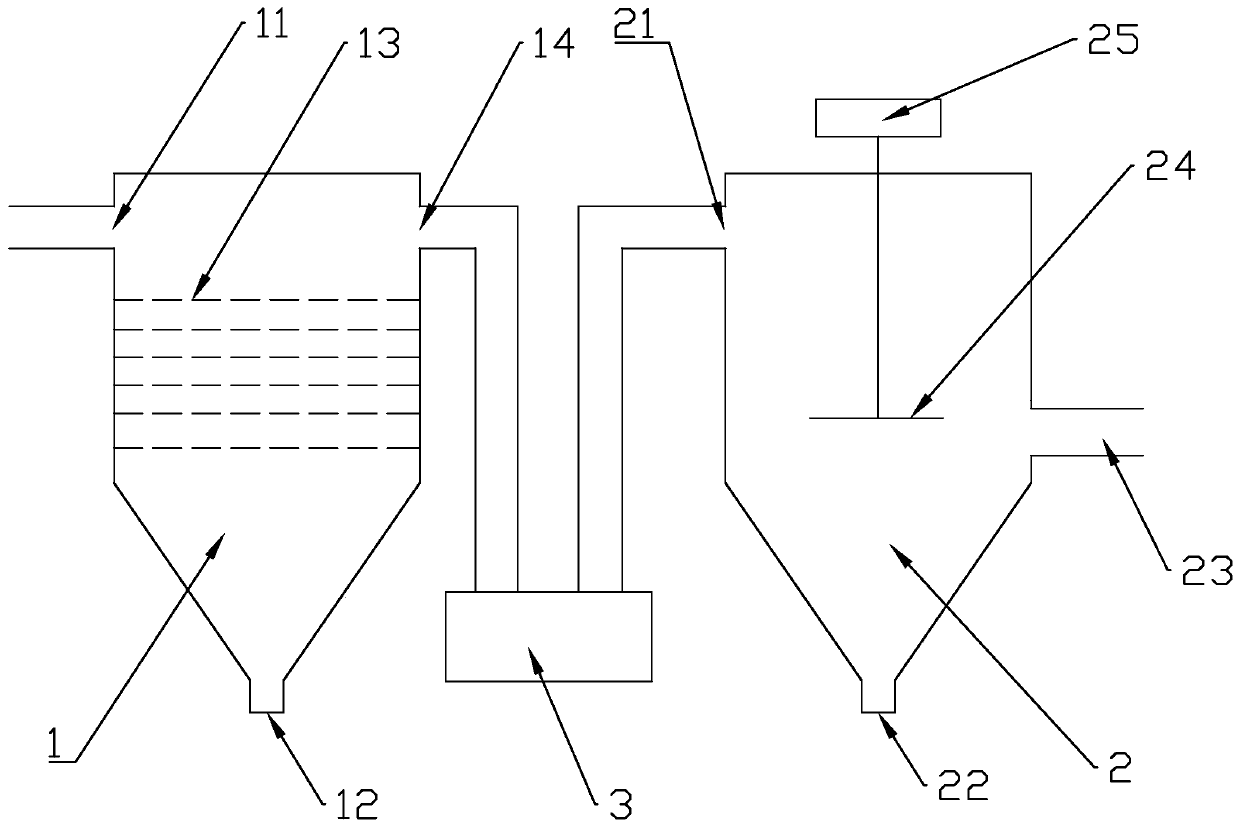

[0038] Such as figure 1 The shown carbonization reactor of the present invention comprises a liquid film nucleator 1 and a crystal grower 2, the upper end of the liquid film nucleator 1 is provided with a slurry inlet-11 and a slurry outlet-14, and the lower end is provided with The gas inlet one 12, the slurry inlet one 11 and the slurry outlet one 14 are respectively located on both sides of the liquid film nucleator 1, and the liquid film nucleator 1 is also provided with a gas distributor 13; the crystal grower 2 The upper end is provided with a slurry inlet 2 21, the lower end is provided with a gas inlet 22 and a slurry outlet 2 23, the crystal grower 2 is also provided with a stirrer 24, and the crystal grower 2 is provided with a motor 25 connected with the stirrer 24 , the first slurry outlet 14 and the second slurry inlet 21 are communicated through the pump 3, and the first slurry inlet, the second slurry inlet, the first gas inlet and the second gas inlet are all e...

Embodiment 2

[0054] A preparation method of a composite surface treatment agent, comprising the following steps:

[0055] (1) Add RHJ-01 simethicone emulsifier into water and soak, stir and mix. The mass ratio of Triton X-100 to water is 1:15. After Triton X-100 is completely dissolved, slowly drop by drop Add simethicone oil, the amount of methicone oil is 2% of the total mass of surfactant and water to obtain a mixed solution, put the mixed solution into a high-speed dispersing emulsifier and rotate at a speed of 2000r / min to make simethicone Dispersed into the surfactant solution to form a homogeneous silicone oil emulsion;

[0056] (2) Stearic acid, sodium hydroxide, and tallow oil are mixed according to a mass ratio of 6:1:4, and a saponification reaction occurs at a reaction temperature of 70° C. to obtain a homogeneous saponified liquid;

[0057] (3) Mix the homogeneous silicone oil emulsion prepared in step (1), the homogeneous saponified liquid prepared in step (2) and KH-550, an...

Embodiment 3

[0060] A preparation method of a composite surface treatment agent, comprising the following steps:

[0061] (1) Soak Triton X-100 in water, stir and mix, the mass ratio of Triton X-100 to water is 1:20, after Triton X-100 is completely dissolved, slowly add dimethylformamide drop by drop Base silicone oil, the amount of methyl silicone oil is 4% of the total mass of surfactant and water to obtain a mixed solution, put the mixed solution in a high-speed dispersing emulsifier and rotate at a speed of 2500r / min to disperse the dimethyl silicone oil on the surface In the active agent solution, a homogeneous silicone oil emulsion is formed;

[0062] (2) Stearic acid, sodium hydroxide, and tallow oil are mixed according to a mass ratio of 6:1:4, and a saponification reaction occurs at a reaction temperature of 90° C. to obtain a homogeneous saponified liquid;

[0063] (3) Mix the homogeneous silicone oil emulsion prepared in step (1), the homogeneous saponified liquid prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com