Preparation method of superhydrophobic polyester fabric and air bubble stirring device

A polyester fabric and stirring device technology, applied in chemical instruments and methods, transportation and packaging, textiles and papermaking, etc., can solve problems such as uneven distribution of finishing agents, fabric surface damage, poor fabric hydrophobic effect, etc., and achieve production efficiency High, good hydrophobic uniformity, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of superhydrophobic polyester fabric, comprises the following steps:

[0035] Step a. prepare the reaction solution, by volume percentage, the reaction solution includes 1-8% hexadecyltrimethoxysilane, 1-16% tetraethyl orthosilicate, 5-15% with a mass fraction of 25 -28% ammonia water and 33-68% absolute ethanol to prepare the reaction solution;

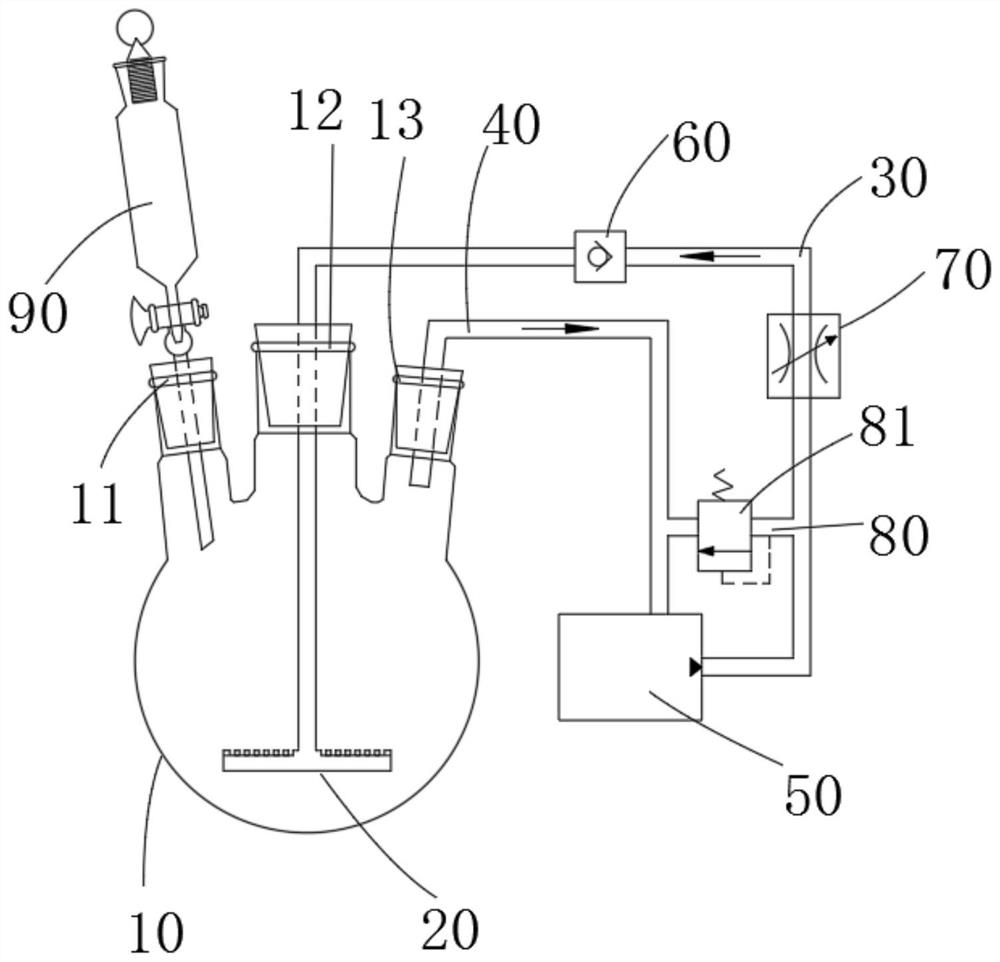

[0036] Step b. adding the reaction solution into a bubble stirring device, soaking the polyester fabric to be treated in the reaction solution for bubble stirring, and obtaining a super-hydrophobic polyester fabric after the stirring is completed.

[0037] Above-mentioned, the step of preparing superhydrophobic polyester fabric is specifically as follows:

[0038] Mix hexadecyltrimethoxysilane, tetraethyl orthosilicate and absolute ethanol, and add ammonia water dropwise while stirring to prepare a reaction solution. Under the catalysis of ammonia water, hexadecyltrimethoxy...

Embodiment 1

[0082] Wash the polyester fabric to be treated, and dry it at 60°C for subsequent use;

[0083] In terms of volume percentage, 5% cetyltrimethoxysilane, 4% tetraethylorthosilicate, 10% ammonia water (25% by mass), and 81% absolute ethanol were prepared as a reaction solution;

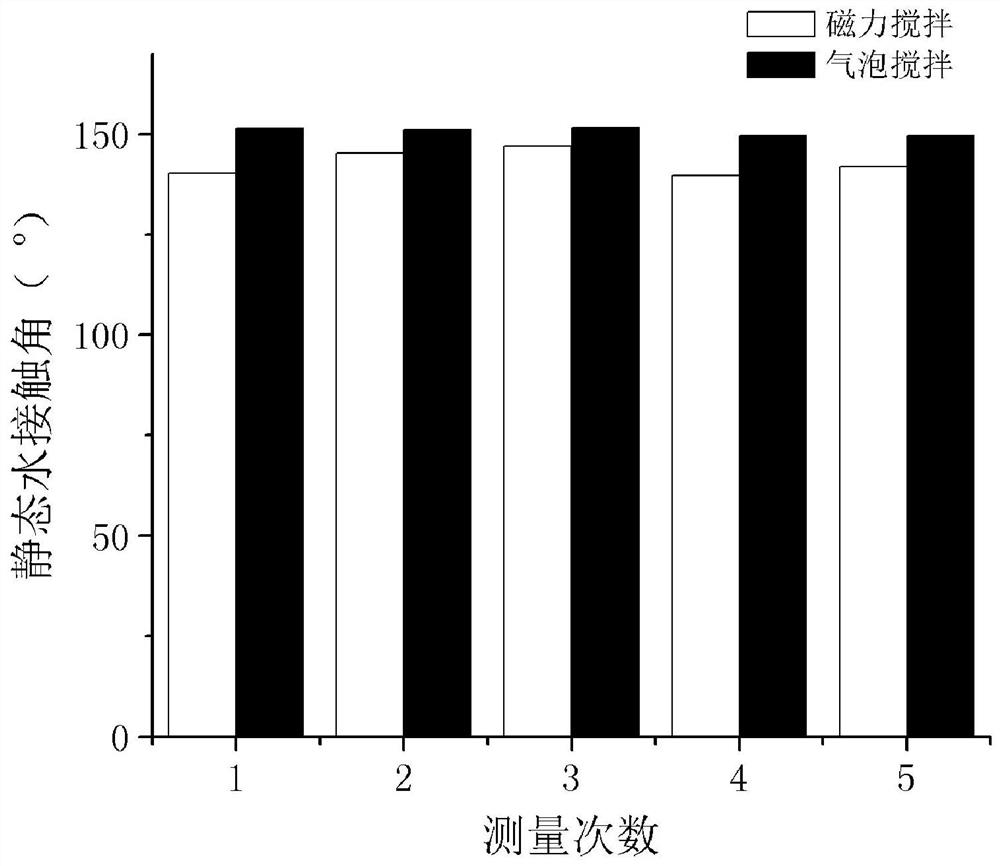

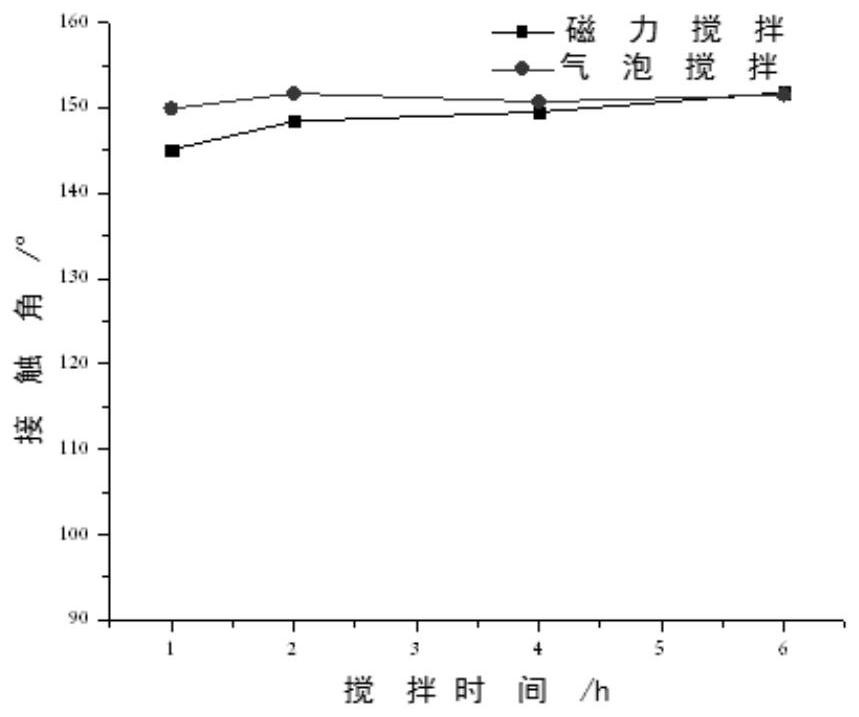

[0084]Add the reaction solution into the bubble stirring device, soak the polyester fabric to be treated in the reaction solution and stir the bubbles for 2 hours, take out the polyester fabric after stirring, rinse the residual liquid on the surface with absolute ethanol, and dry it at 130°C for 1 hour to obtain a super Hydrophobic polyester fabric.

Embodiment 2

[0086] The reaction solution in Example 1 is prepared as follows: by volume percentage, 5% of hexadecyltrimethoxysilane, 2% of tetraethyl orthosilicate, 10% of ammonia water (mass fraction is 25%) , 83% absolute ethanol to prepare the reaction solution. Other steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com