Micro-extraction component, super-gravity field micro-extraction device and extraction method

An extraction device and extraction technology, which are applied in chemical instruments and methods, solvent extraction, separation methods, etc., can solve the problems of small processing capacity and affect mass transfer performance, and achieve short phase separation time, high extraction rate, and shortened extraction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

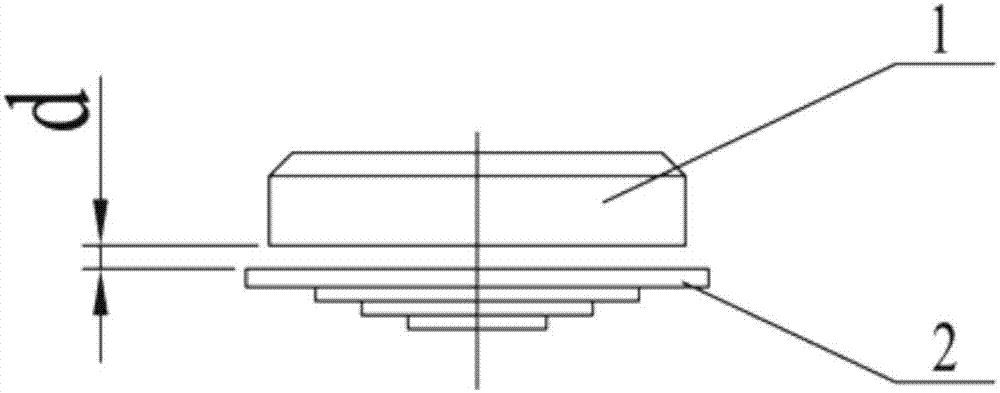

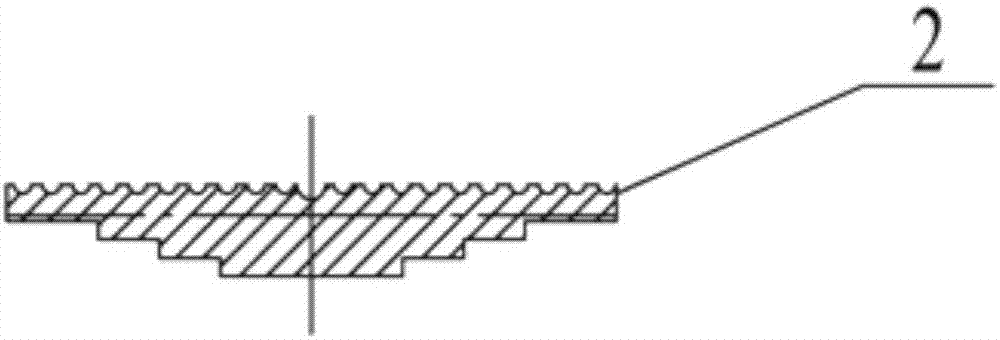

Embodiment 1

[0042] In this example, the micro-extraction components such as figure 1 , figure 2 , image 3 As shown, it is composed of lipophilic upper plate 1 and hydrophilic lower plate 2; the density of the upper plate 1 is 0.950g / cm 3 Made of polyethylene, its shape is truncated circular, the diameter of the circular truncated is 90mm, the bottom surface of the upper plate is flat, and the first screw hole 1-1 and the microfluidic channel 1-2 are arranged in the center from top to bottom in sequence. Channel 1-2 is a circular hole-shaped channel with a diameter of 1mm. The first screw hole 1-1 is used for installation and fixing; The diameter of the upper circular platform is 100 mm, the center of the top surface of the lower plate is provided with a feed groove 2-1, and there are spiral micro-shaped grooves 2-2 distributed from the feed groove to the edge of the top surface of the lower plate, such as Figure 4 As shown, the width of the spiral micro-groove is 0.5mm, and the dept...

Embodiment 2

[0044] In this embodiment, the supergravity field micro-extraction device such as Figure 8 , Figure 9 As shown, it includes the micro-extraction assembly described in Example 1, a feed mixer 14, a coupling body 15, a receiving tank 11, a protective cover 10, a shaft sleeve 12, a reducer 8, a motor 7, a flat key 16 and a support system; The support system consists of a truncated conical base 5, four circular cross-section columns 6 evenly distributed and fixed on the base, and circular first bearing plates 9 and circular second bearing plates mounted on the columns at a certain interval. Plate 13 is formed; The feed mixer is as Figure 10 As shown, it is a three-way pipe composed of circular pipes with an inner diameter of 0.8mm and an outer diameter of 1mm. There are two feed pipes and one discharge pipe. The angle α between the centerlines of the two feed pipes is 120° ; The coupling body 15 is as Figure 13 As shown, it is a stepped circular frustum with a large top and...

Embodiment 3

[0046] In this example, the high-gravity field micro-extraction device described in Example 2 was used to extract wet-process phosphoric acid. The main composition of the purified wet-process phosphoric acid is shown in Table 1.

[0047] Table 1 Composition of purified wet-process phosphoric acid

[0048] components

P 2 o 5

Fe 3+

SO 4 2-

F -

Contentwt%

45.41

0.57

5.06

0.13

[0049] The extractant is prepared from tributyl phosphate (TBP) and kerosene at a volume ratio of 5:1, and the ratio of the organic phase (extractant) to the aqueous phase (purified wet-process phosphoric acid) is 4:1.

[0050] The operation is as follows:

[0051] (1) Tributyl phosphate (TBP) and kerosene are prepared as an extraction agent at a volume ratio of 5:1 and the extraction agent is preheated to 50°C;

[0052] (2) Start the motor so that the power output shaft of the reducer drives the lower plate 2 to rotate at a speed of 250rad / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com