Thermal insulation board and insulation box, wall or floor panel using the same

A technology for heat insulation and heat preservation boxes, applied in the field of wall panels and heat preservation boxes, which can solve the problems of shortening the service life of vacuum heat insulation panels, affecting the overall shape, and not being resistant to corrosion, so as to improve indoor heat preservation performance, facilitate installation and replacement, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

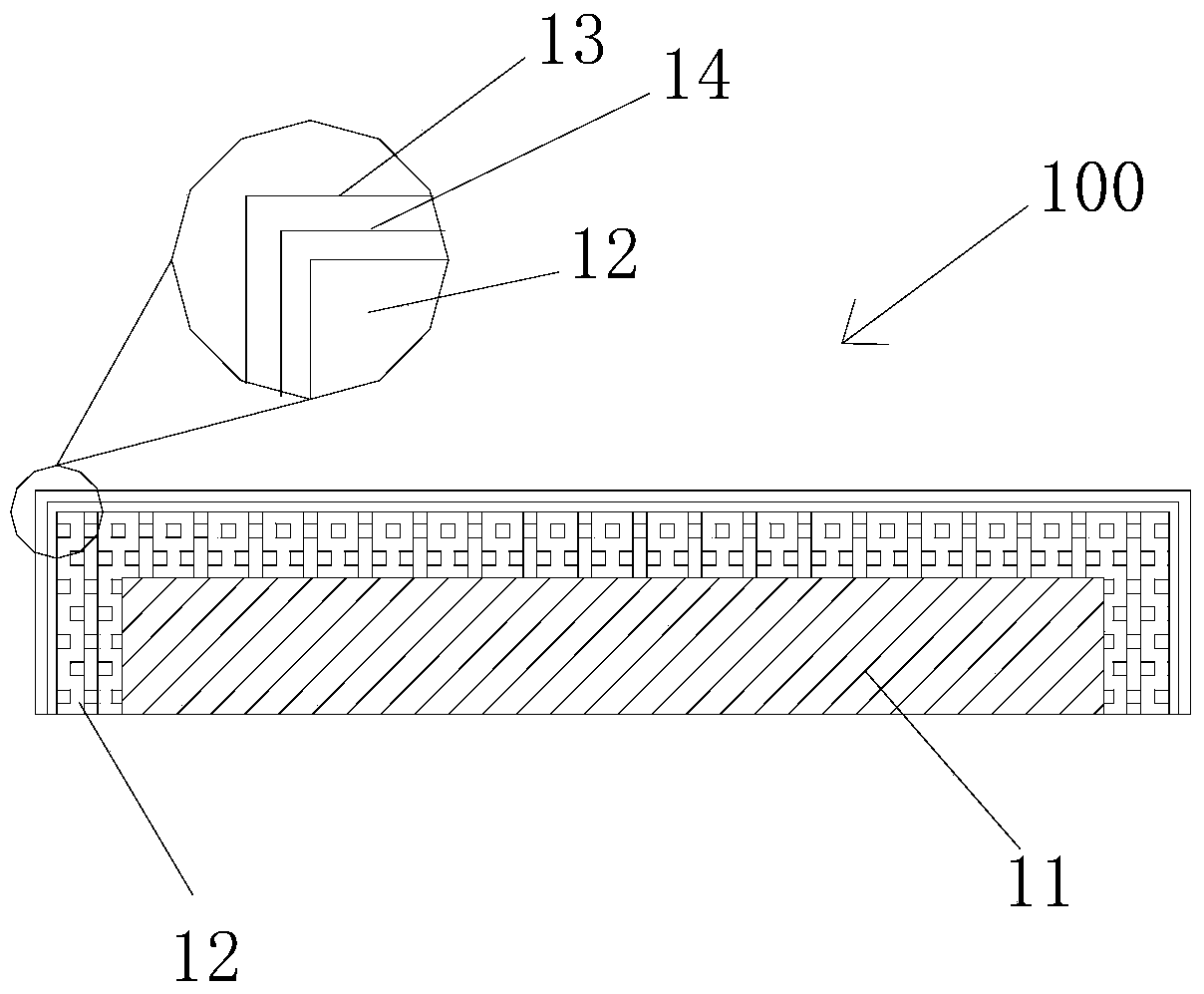

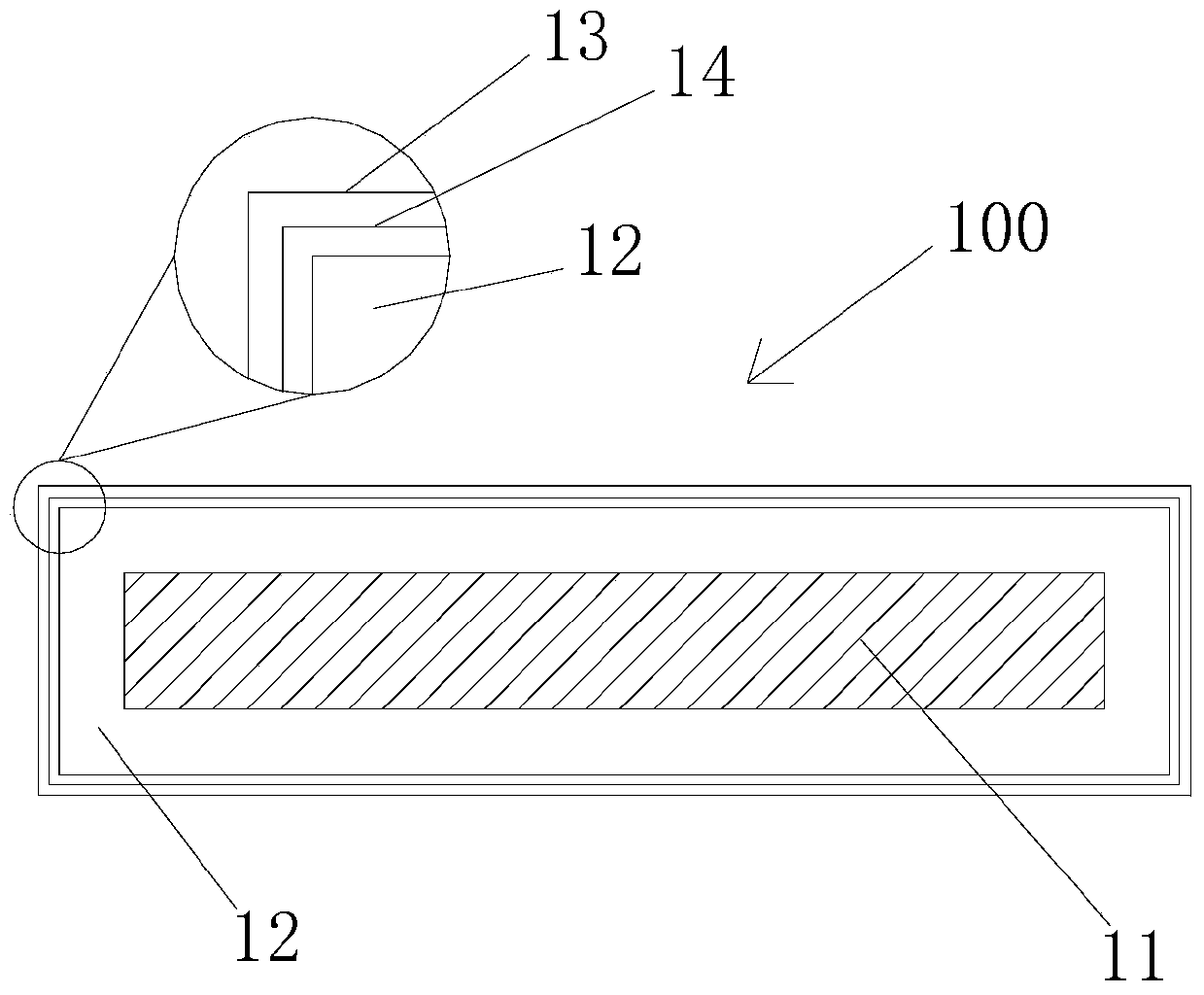

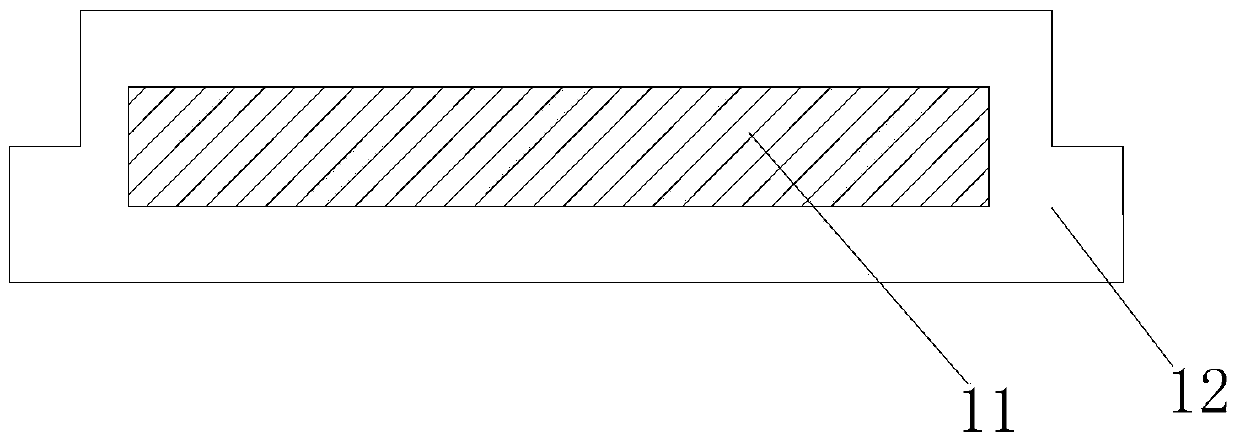

[0039] See Figures 1 to 11 The thermal insulation panel 100 of this embodiment includes: a vacuum insulation panel 11 , a foam material 12 covering at least one side of the vacuum insulation panel 11 , or the foam material 12 covers the vacuum insulation panel 11 entirely. An aluminum film 13 is provided on the outside of the foam material, or the outside of the foam material is coated with metallic paint.

[0040] A non-woven fabric or glass fiber layer 14 is provided between the foam material 12 and the aluminum film 13, and the aluminum film 13 is an aluminized film or an aluminum foil film or an aluminum-plastic film; or, a non-woven fabric is coated on the foam material Or glass fiber cloth, coated with metallic paint (preferably aluminum powder paint). Among them, the setting of the glass fiber layer can further improve the fire performance.

[0041] The thermal insulation board is rectangular, and at least one pair of symmetrical edges is provided with steps or slope...

Embodiment 2

[0047] like Figure 12-15 , the foldable portable incubator 1 of the present embodiment adopts a rectangular box body made of heat-insulating aluminized film or aluminum foil film or aluminum-plastic film material, and the top of the box body has a box cover that can be opened; , rear plate, left plate, right plate, and bottom plate constitute the cavity; the top port of the cavity is open, and the inner side of the box cover is provided with a cover plate 2. When the box cover closes the box body, the cover plate 2 is suitable for inserting into the container The top port of the cavity, or the cover plate 2 is suitable for integrally covering the top port of the cavity; the front plate, the rear plate, the left plate, the right plate, the bottom plate and the cover plate all include: a thermal insulation core plate (preferably a vacuum insulation panel, foam panels, vacuum insulation panels coated with foam, etc.).

[0048] Heat-insulating aluminized film or aluminum foil fi...

Embodiment 3

[0057] On the basis of Embodiment 1, there are the following modifications in this embodiment:

[0058] like Figure 16-18 , sew trapezoidal wear-resistant cloth 8 (preferably canvas) on the bottom surface of the box close to each end corner, and make each end angle on the bottom surface of the bottom plate not covered by wear-resistant cloth; insert wear-resistant sheet 9 (preferably silicon rubber) The boss of the wear-resistant sheet is inserted into the wear-resistant cloth, and the wear-resistant sheet 9 is basically a triangular body, and a boss 91 is provided at the end corner of the wear-resistant sheet 9; the boss 91 is arranged on each end of the bottom surface of the box body The corners are not covered by wear-resistant cloth, which plays the role of anti-collision and anti-friction. When in use, if one end is lifted to drag the box body, since the boss of the wear-resistant sheet at the landing end acts as a fulcrum, the bottom surface of the box body is protecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com