Infrared metamaterial absorber and preparation method therefor

A technology of material absorption and infrared ultrasonography, applied in the field of infrared detection, can solve the problems of low signal response efficiency, achieve the effects of easy fabrication and arrangement, simplified process, and perfect absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Its preparation method comprises the following steps:

[0048] (1) Provide a base 1, the material of the base 1 is silicon or gallium arsenide;

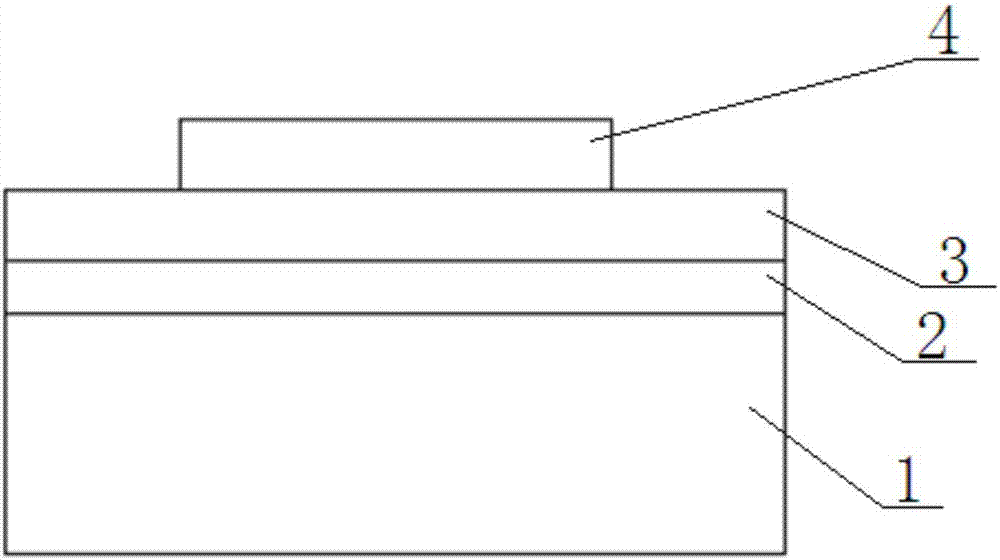

[0049] (2) grow thin film layer 2 on described substrate 1, the material of described thin film layer 2 is any one in gold, silver, copper aluminum, thickness is not more than 200nm, adopts electron beam evaporation or magnetron sputtering method to form ;

[0050](3) Growing a dielectric layer 3 on the thin film layer 2, the material of the dielectric layer 3 is any one of silicon nitride, silicon oxide, aluminum oxide, and magnesium fluoride, and the thickness is not more than 300nm. Formation by any one of evaporation, magnetron sputtering, atomic layer deposition, and plasma enhanced chemical vapor deposition;

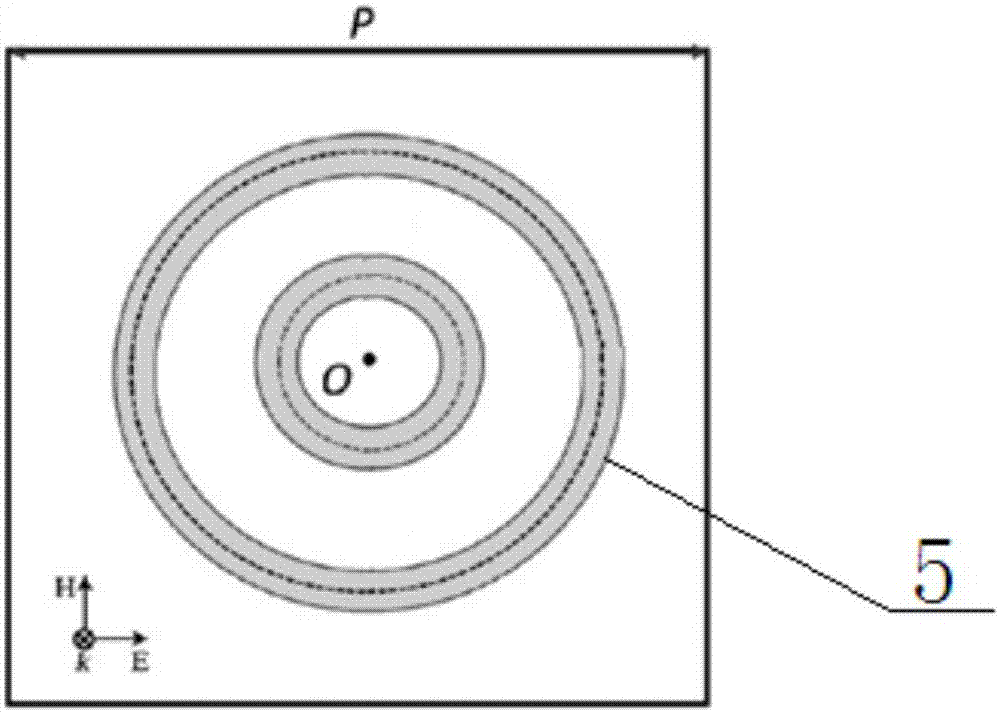

[0051] (4) Form a resonant ring structure layer 4 on the dielectric layer 3, the resonant ring structure layer 4 includes at least one metal nano-ring 5, the radius of the metal nano-ring 5 is not more than 2000n...

Embodiment 1

[0055] Such as figure 1 , figure 2 As shown, an infrared metamaterial absorber described in this embodiment includes a substrate 1, a film layer 2, a dielectric layer 3, and a resonant ring structure layer 4 arranged in sequence, and the resonant ring structure layer 4 includes at least one metal nanometer Ring 5.

[0056] Its specific preparation method is as follows:

[0057] (1) Provide a base 1, the material of the base 1 is silicon or gallium arsenide;

[0058] (2) growing a thin film layer 2 on the substrate 1, which is formed by electron beam evaporation or magnetron sputtering;

[0059] (3) growing a dielectric layer 3 on the thin film layer 2, using any one of electron beam evaporation, magnetron sputtering, atomic layer deposition, and plasma enhanced chemical vapor deposition;

[0060] (4) Forming a resonant ring structure layer 4 on the dielectric layer 3, the resonant ring structure layer 4 includes at least one metal nanoring 5, adopts deep ultraviolet litho...

Embodiment 2

[0063] According to Embodiment 1, an infrared metamaterial absorber described in this embodiment, the substrate 1 is made of p-type doped silicon, the thin film layer 2 is made of gold, and the thickness is 100nm; the dielectric layer 3 is made of silicon oxide. , thickness is 250nm; the quantity of metal nanoring 5 is 1, adopts gold as material, and thickness is 100nm, and the radius of metal nanoring 5 is 450nm, and width is 100nm; Period P is 2400nm, adopts the preparation method described in embodiment 1 Prepare to become a finished product. With this embodiment, total absorption of waves around 4300 nm in the mid-infrared can be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com