Steel-plastic composite pipe corridor body member and forming technology thereof

A technology of steel-plastic composite pipes and corridors, applied in industrial buildings, etc., can solve problems such as increased construction costs and maintenance costs, long processing and production cycles, and difficult hoisting construction, so as to save material costs and service life problems, and save labor Cost and material saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

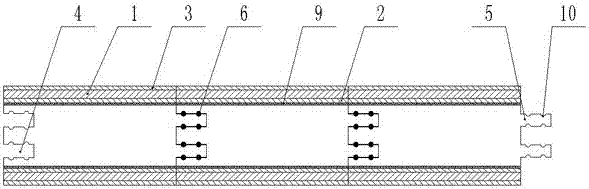

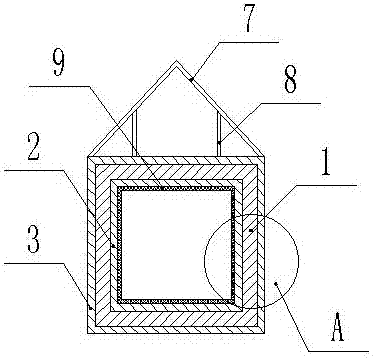

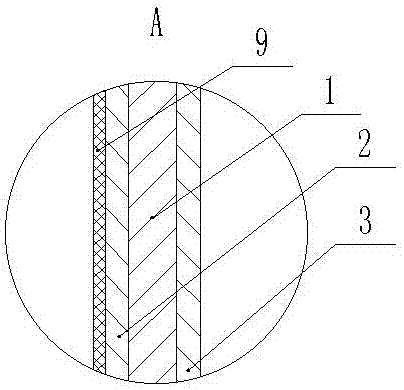

[0024] Such as Figure 1 to Figure 5 As shown, a steel-plastic composite pipe corridor body part of the present invention includes a skeleton body 1, and the skeleton body 1 is a steel plate structure, and four pieces of the skeleton body 1 are welded to form a square tubular structure with a square section. A plastic inner layer 2 and a plastic outer layer 3 are respectively provided on the inner and outer sides of the tubular structure. Grooves 4 are provided on the four sides of one end of the tubular structure, and protrusions 5 are provided on the four sides of the other end. The grooves 4 and protrusions 5 between the tubular structures are matched and snapped together to form a pipe gallery, the protrusions 5 are covered with a sealing ring 6, and the joints between adjacent tubular structures The seam is coated with hot-melt adhesive, so that the adjacent tubular structures are firmly connected and can be kept sealed.

[0025] The top of each said tubular structure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com