Urea formaldehyde resin-coated isocyanate microcapsule and preparation method thereof

A technology of isocyanate and urea-formaldehyde resin, applied in the field of preparation of microcapsule composite materials, can solve the problems of short aging period, poor stability and bad smell of isocyanate, and achieve the effects of short aging period, high encapsulation rate and easy transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

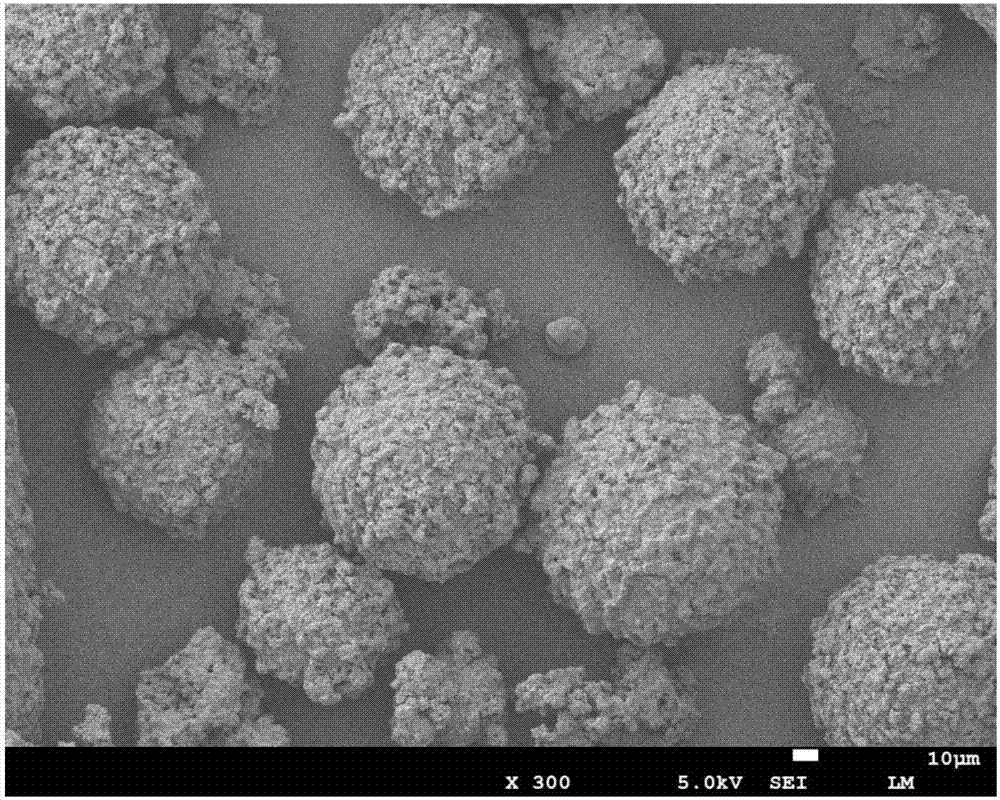

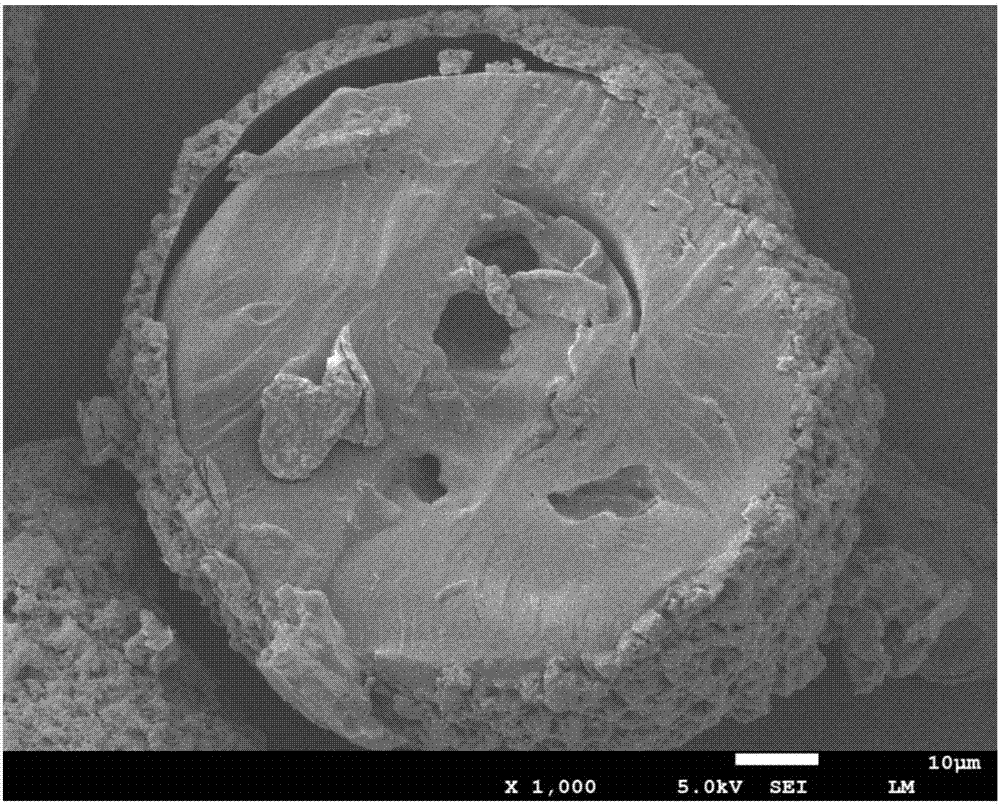

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the urea-formaldehyde resin-wrapped isocyanate microcapsules described in the above technical solution, comprising the following steps:

[0044] (1) carry out condensation reaction after formaldehyde, urea and alkaline pH regulator are mixed, obtain urea-formaldehyde resin prepolymer;

[0045] (2) mixing the urea-formaldehyde resin prepolymer obtained in the step (1) with an emulsifier, a system stabilizer and water to obtain an aqueous phase;

[0046] mixing isocyanate and isocyanate protecting agent to obtain an oil phase;

[0047] emulsifying the water phase and the oil phase to obtain an emulsion;

[0048] (3) The emulsion obtained in the step (2) is mixed with an acidic pH regulator and then cured to obtain isocyanate microcapsules wrapped in urea-formaldehyde resin.

[0049] In the invention, the formaldehyde, urea and alkaline pH regulator are mixed and condensed to obtain the urea-formaldehyde resin p...

Embodiment 1

[0064] The microcapsules of urea-formaldehyde resin-wrapped isocyanate of the present embodiment are prepared from raw materials according to the following weight percentages: water: 29%; formaldehyde (37% by mass fraction): 5%; urea: 2%; emulsifier: 0.1 %; system stabilizer: 0.2%; isocyanate: 17%; isocyanate protective agent: 2%; acidic pH regulator 0.05%; alkaline pH regulator 0.05%.

[0065] Wherein, the emulsifier is sodium dodecylbenzene sulfonate; the system stabilizer is polyvinyl alcohol; the isocyanate is polymethylene polyphenyl polyisocyanate (PAPI); the isocyanate protective agent is toluene, and the alkaline pH regulator is hydrogen Sodium oxide; the acidic pH adjuster is hydrochloric acid.

[0066] The specific preparation method is as follows:

[0067] Put the formaldehyde solution and urea into the kettle and stir until dissolved, add an alkaline pH regulator to make the pH 8, and at 60°C, mechanically stir at 900rpm to undergo condensation reaction for 60min ...

Embodiment 2

[0077] The raw materials and preparation steps of Example 2 are exactly the same as those of Example 1, and the only difference from Example 1 is that the rotational speed of the condensation reaction for preparing the urea-formaldehyde resin prepolymer is 800rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com