N-doped CrO2 epitaxial thin film and preparation method thereof

A technology of epitaxial thin film and doping concentration, applied in the field of materials, can solve the problems of not expanding the preparation temperature range and the thermal stability of the thin film, the film forming rate, and improving the thermal stability, and achieve the thermal stability and preparation temperature range. Improved, easy operation, improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

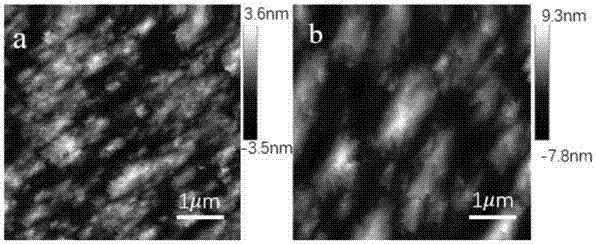

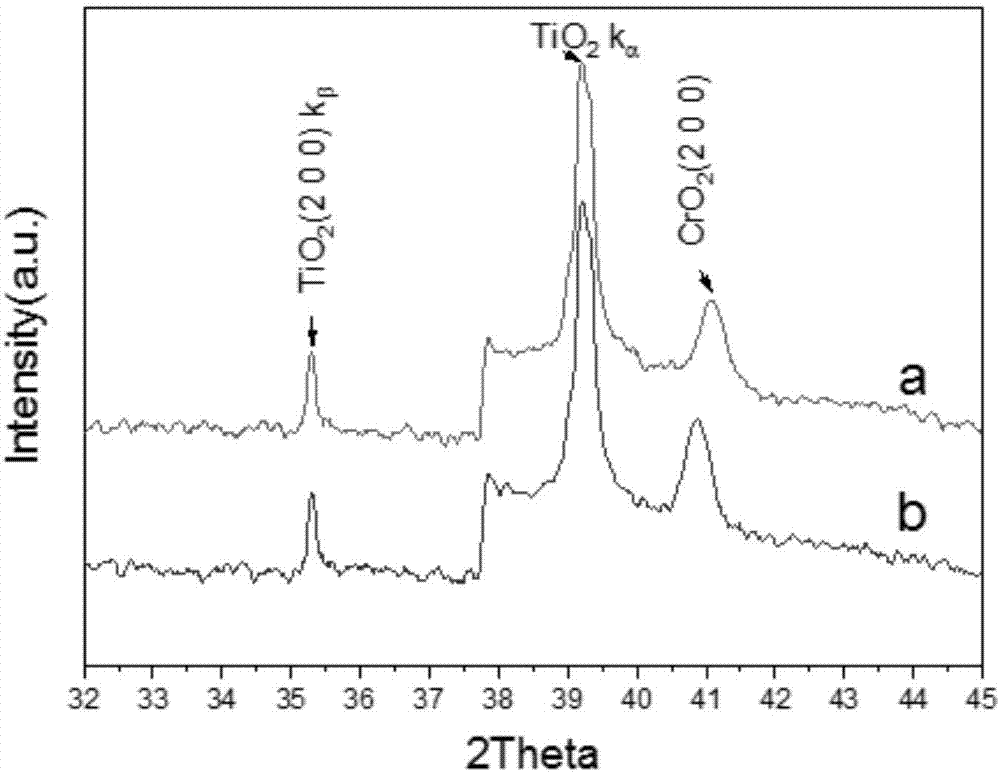

[0025] A N-doped CrO 2 The preparation method of epitaxial film, the preparation method described in this embodiment comprises the following steps:

[0026] Step 1, first 75 parts of quality CrO 3 Put it into the quartz boat, put the quartz boat into the low temperature zone of the dual temperature zone tube furnace, and then put the TiO 2 The single crystal substrate is placed in the high temperature zone of the dual temperature zone tube furnace;

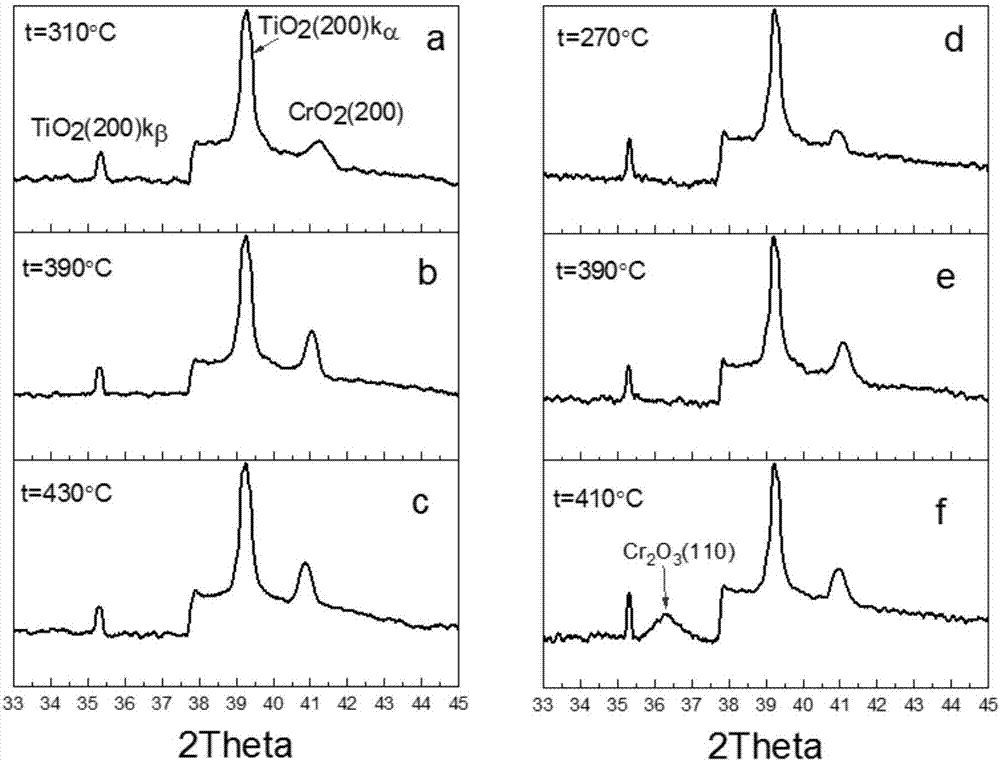

[0027] Step 2, continuously feed N into the tube furnace at a flow rate of 160mL / min 2 Under certain conditions, heat the high temperature zone to 310°C and start keeping warm;

[0028] Step 3: When the high-temperature zone starts to keep warm, start heating the low-temperature zone, heat the low-temperature zone to 260 ° C, and then keep the high-temperature zone and low-temperature zone for 3.5 hours, that is, in the TiO 2 N-doped CrO prepared on single crystal substrate 2 epitaxial film.

Embodiment 2

[0030] A N-doped CrO 2 The preparation method of epitaxial film, the preparation method described in this embodiment comprises the following steps:

[0031] Step 1, first 75 parts of quality CrO 3 Put it into the quartz boat, put the quartz boat into the low temperature zone of the dual temperature zone tube furnace, and then put the TiO 2 The single crystal substrate is placed in the high temperature zone of the dual temperature zone tube furnace;

[0032] Step 2, continuously feed N into the tube furnace at a flow rate of 150mL / min 2 Under certain conditions, heat the high temperature zone to 390°C and start keeping warm;

[0033] Step 3: When the high-temperature zone starts to keep warm, start heating the low-temperature zone, heat the low-temperature zone to 260°C, and then keep the high-temperature zone and low-temperature zone for 1.5 hours, that is, in the TiO 2 N-doped CrO prepared on single crystal substrate 2 epitaxial film.

Embodiment 3

[0035] A N-doped CrO 2 The preparation method of epitaxial film, the preparation method described in this embodiment comprises the following steps:

[0036] Step 1, first 75 parts of quality CrO 3 Put it into the quartz boat, put the quartz boat into the low temperature zone of the dual temperature zone tube furnace, and then put the TiO 2 The single crystal substrate is placed in the high temperature zone of the dual temperature zone tube furnace;

[0037] Step 2, continuously feed N into the tube furnace at a flow rate of 150mL / min 2 Under certain conditions, heat the high temperature zone to 430°C and start keeping warm;

[0038] Step 3: When the high-temperature zone starts to keep warm, start heating the low-temperature zone, heat the low-temperature zone to 260°C, and then keep the high-temperature zone and low-temperature zone for 1.5 hours, that is, in the TiO 2N-doped CrO prepared on single crystal substrate 2 epitaxial film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com