Preparing method of carbon nanometer tube reinforced tungsten copper composite material

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of carbon nanotube-reinforced tungsten-copper composite materials, can solve the problems affecting the performance of WCu composite materials and the integrity of tungsten skeleton, so as to improve the performance of arc ablation resistance, Effect of improving wear resistance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, mix powder:

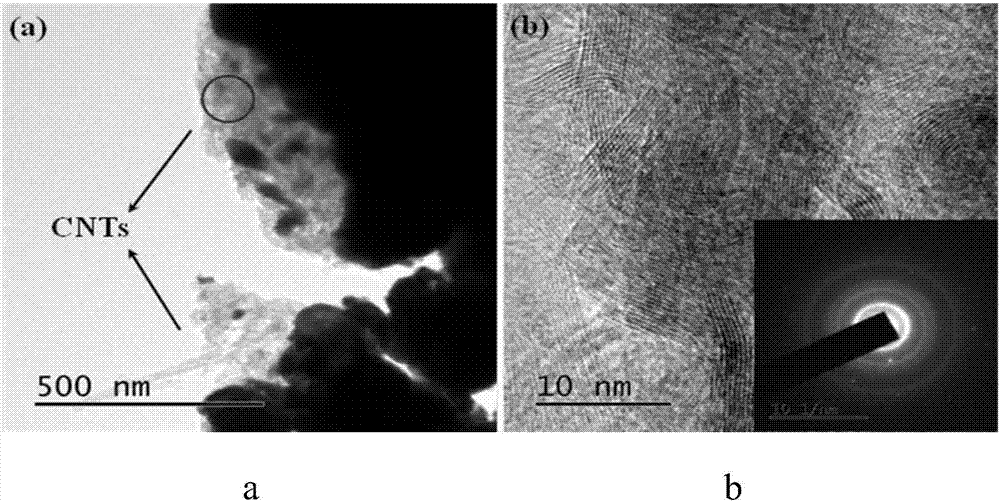

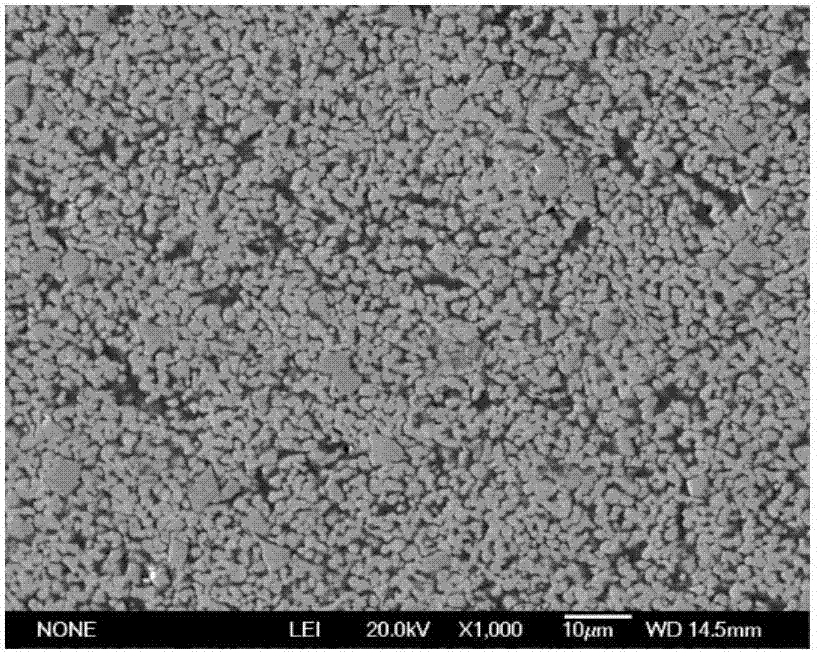

[0037] After mixing tungsten powder, copper powder and CNTs according to the ratio of 79% W, 20% Cu and 1% CNTs, they were mixed in a high-energy ball mill at a speed of 200r / min for 12 hours according to a ball-to-material ratio of 10:1 to make them evenly mixed to obtain WCu mixed powder with dispersed distribution of CNTs;

[0038] Step 2, suppress:

[0039] The mixed powder obtained in step 1 is pre-compressed and maintained on a hydraulic press according to the compactness of the green body after pressing to 40%, the pre-compression pressure to 200 MPa, and the holding time to 90s to obtain a composite material green body;

[0040] Step 3, liquid phase sintering and infiltration:

[0041] The composite material green body obtained in step 2 is heated in a computer-programmed high-temperature hydrogen atmosphere sintering furnace at a heating rate of 25°C / min. When the temperature reaches 1300°C, it is kept for 120 minutes and then cooled wit...

Embodiment 2

[0043] Step 1, mix powder:

[0044] After mixing tungsten powder, copper powder and CNTs according to the ratio of 75% W, 23% Cu and 2% CNTs, they were mixed in a high-energy ball mill at a speed of 300r / min for 10 hours according to a ball-to-material ratio of 3:1 to make them evenly mixed to obtain WCu mixed powder with dispersed distribution of CNTs;

[0045] Step 2, suppress:

[0046] The mixed powder obtained in step 1 is pre-compressed and maintained on a hydraulic press according to the compactness of the green body after pressing to 60%, the pre-compression pressure to 400 MPa, and the holding time to 60s to obtain a composite material green body;

[0047] Step 3, liquid phase sintering and infiltration:

[0048] The composite material green body obtained in step 2 is heated in a computer-programmed high-temperature hydrogen atmosphere sintering furnace at a heating rate of 20°C / min. When the temperature reaches 1400°C, it is kept for 80 minutes and then cooled with ...

Embodiment 3

[0050] Step 1, mix powder:

[0051]After mixing tungsten powder, copper powder and CNTs according to the ratio of 72% W, 25% Cu and 3% CNTs, they were mixed in a high-energy ball mill at a speed of 400r / min for 8 hours according to a ball-to-material ratio of 5:1 to make them evenly mixed to obtain WCu mixed powder with dispersed distribution of CNTs;

[0052] Step 2, suppress:

[0053] The mixed powder obtained in step 1 is pre-compressed and maintained on a hydraulic press according to the compactness of the green body after pressing to 50%, the pre-compression pressure to 340 MPa, and the holding time to 30s to obtain a composite material green body;

[0054] Step 3, liquid phase sintering and infiltration:

[0055] The composite material green body obtained in step 2 is heated in a computer-programmed high-temperature hydrogen atmosphere sintering furnace at a heating rate of 15°C / min. When the temperature reaches 1350°C, it is kept for 40 minutes and then cooled with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com