Self-lubricating structure of double-row heavy-load cement conveying chain

A conveyor chain, self-lubricating technology, used in conveyor objects, transportation and packaging, cleaning devices, etc., can solve problems such as increasing the lubrication performance of the chain itself, link jamming, dust and corrosive substances entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

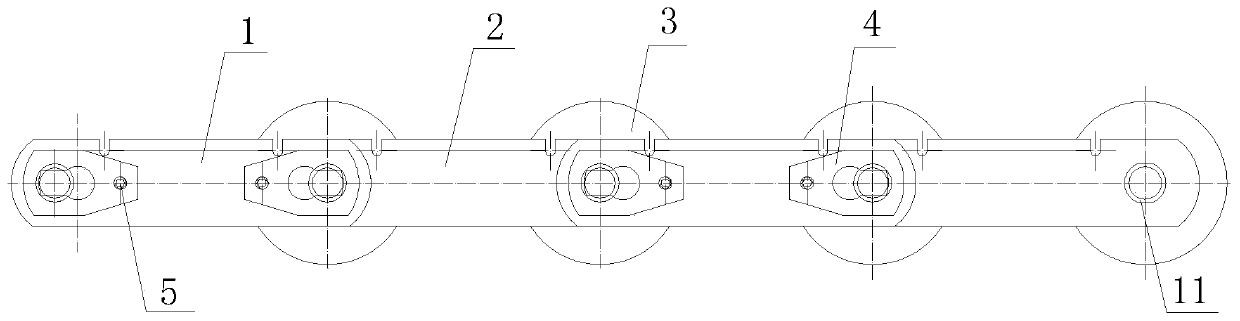

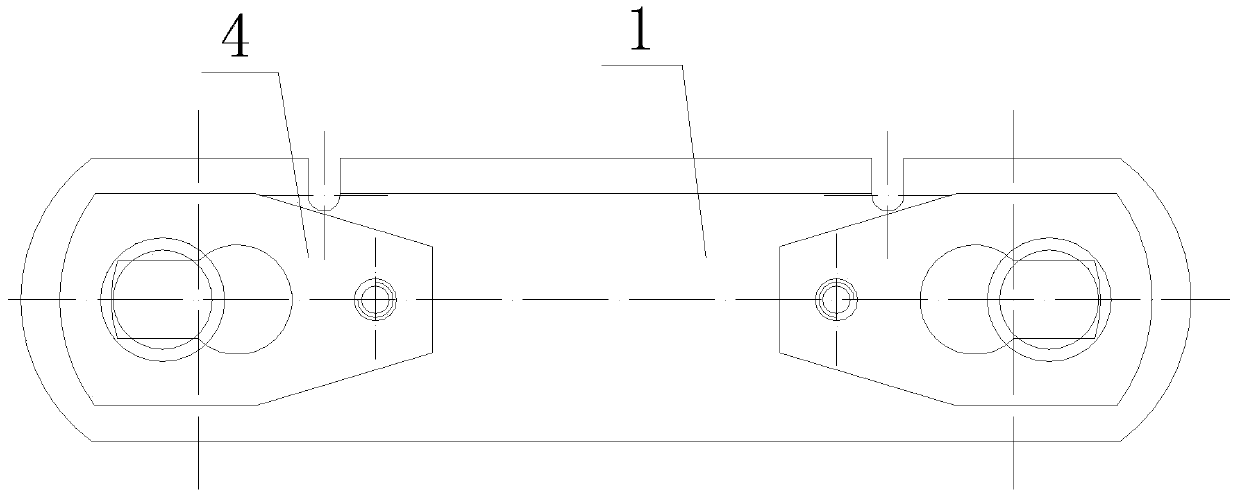

[0037] Attached below Figure 1-11 The present invention is further described with embodiment:

[0038] A self-lubricating structure of a double-row heavy-duty cement conveyor chain, including two sets of closed structures surrounded by several chain links, and the two sets of closed structures are arranged in parallel, and each chain link includes an inner chain plate 2, an outer chain plate 1 and a pin shaft 10. The outer chain plates 1 and the inner chain plates 2 are alternately connected in pairs through the pin shafts 10, and rollers 3 are provided between the two inner chain plates 2, and the rollers 3 A sleeve 11 is inserted in the middle, and the sleeve 11 is sleeved on the pin shaft 10, and there is a large gap between the pin shaft 10 and the sleeve 11, and the inner end of the pin shaft 10 is provided with a terminal Steps, and the other end of the pin shaft 10 is provided with an oil groove, the port of the oil groove is threaded with an oil cup 6, and the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com