An electrolysis-ion membrane coupled device and method for treating high-chloride organic wastewater

A technology of organic wastewater and ionic membrane, which is applied in the direction of ion exchange water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing treatment costs, difficulty in meeting discharge standards for organic matter content in wastewater, and high difficulty. Achieve the effects of strong conductivity and chemical resistance, lower real current density, and long plate life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Wastewater treatment of an organic dye processing enterprise

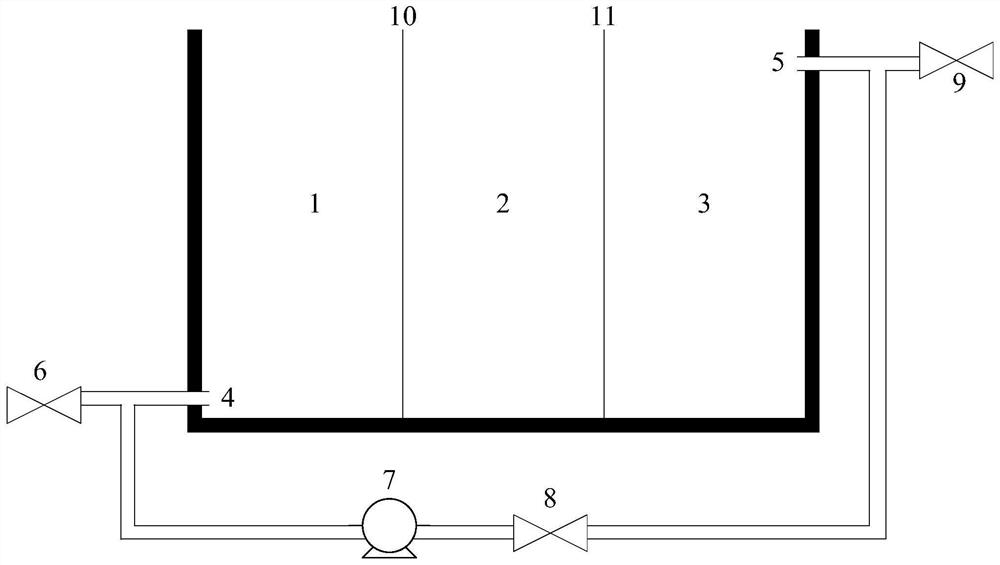

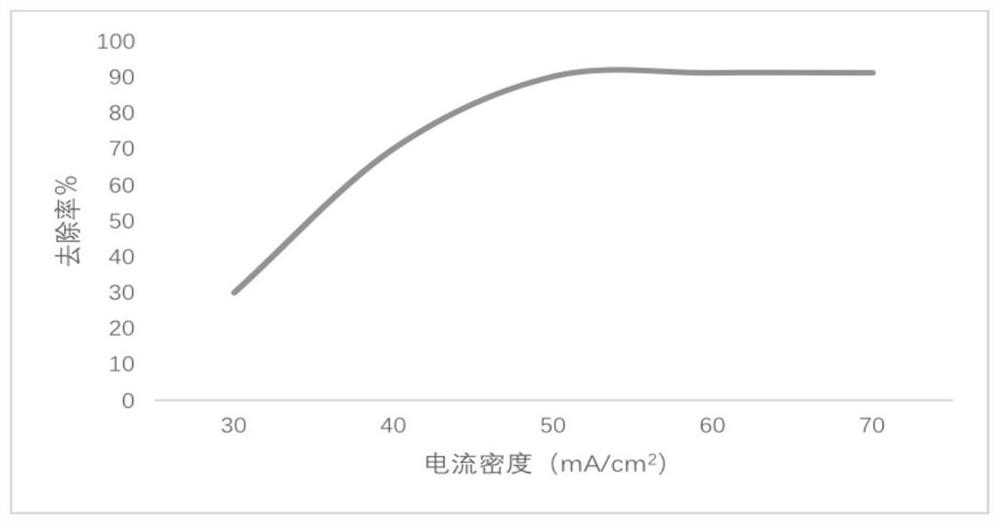

[0041] The wastewater from this enterprise mainly contains azo dyes direct dark brown and acid scarlet. The concentration is about 2000mg / L, and the salinity in the raw wastewater is as high as 50000mg / L. Conventional biological treatment is difficult to achieve the effect. In the present invention, first introduce the organic waste water into a self-made electrolytic cell equipped with a titanium-based iridium dioxide-plated DSA anode and a carbon felt cathode. 2 , Electrolysis time: 90min. During the electrolysis process, the reactor is filled with waste water, and the waste water is continuously circulated from the anode chamber to the cathode chamber through a peristaltic pump to form a circulation loop. Test results such as figure 2 shown.

[0042] From figure 2 It can be seen that after 90min, the current density is 30mA / cm 2 When the removal rate of organic matter is 30%; the curre...

Embodiment 2

[0043] Example 2: Treatment of dyeing wastewater in a fur processing enterprise

[0044] The fur processing enterprise mainly processes wool products. During the dyeing stage, various dyes such as phenols, acrylics, and tannins are added, with a concentration of 2000-6000 mg / l. The salinity of the raw wastewater is about 3%. Conventional biochemical methods need to add a large amount of flocculation The organic matter content of wastewater after biochemical treatment is still difficult to meet the discharge standard, and the chroma is still high. Adopt the method of the present invention, at first introduce this organic waste water in the self-made electrolyzer that is equipped with titanium-based iridium dioxide-plated DSA anode, carbon felt cathode, the volume of electrolyzer is 25L, control current density: 50mA / cm 2 , Electrolysis time: 40 ~ 100min. During the electrolysis process, the reactor is filled with waste water, and the waste water is continuously circulated from...

Embodiment 3

[0045] Example 3: Wastewater treatment of a pharmaceutical company

[0046] The wastewater produced by the pharmaceutical company is strongly acidic, high-salt, and high-organic wastewater. The chloride ion in the wastewater is about 60,000 mg / L, and the COD is about 50,000 mg / L. Due to the large amount of salt, conventional biochemical methods are difficult to operate, and the three-phase evaporation method is usually used to treat the salt in wastewater, which is extremely costly. By adopting the method of the present invention, waste water is passed into a self-made electrolytic cell equipped with a titanium-based iridium dioxide-plated DSA anode and a carbon felt negative electrode. The volume of the electrolytic cell is 25L, and the control current density is 50mA / cm 2 , Electrolysis time: 90min. Due to the complex composition of organic matter in wastewater, the removal rate of organic matter is basically maintained at about 60%, and 0.25mol / L Fe is added to the cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com