Sulfydryl cellulose porous material as well as preparation method and application thereof

A technology of porous materials and cellulose, applied in other chemical processes, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of unenvironmental protection of reaction reagents, cumbersome preparation process, and low sulfhydryl content, and achieve Effects of improving mechanical properties, abundant sources, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

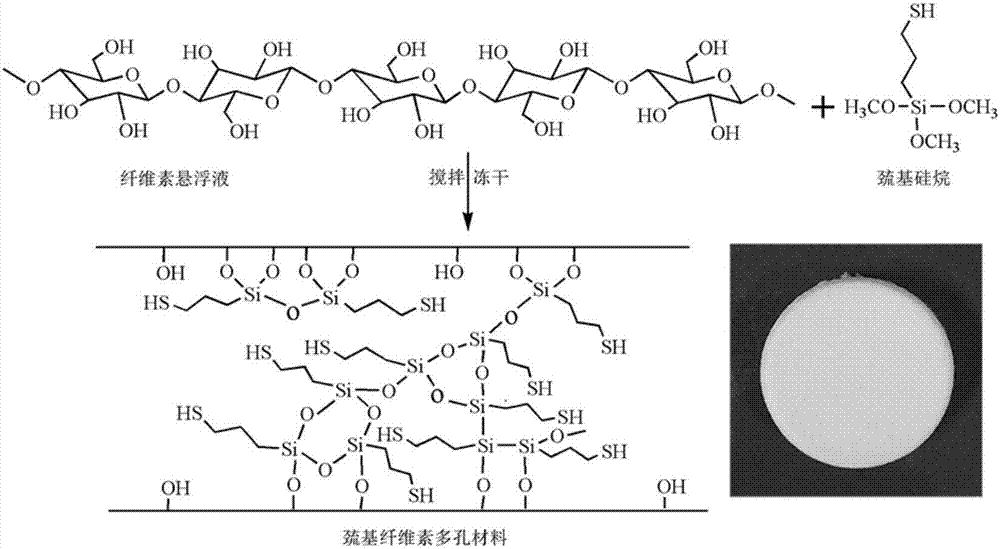

[0028] (1) Weigh 10g of 1.2wt% wood pulp cellulose nanowire suspension, the diameter of cellulose nanowire is 1-200nm, and the length is 50-700nm; add mercaptosilane coupling agent KH-590 to cellulose nanowire In the suspension, at room temperature, use hydrochloric acid to adjust pH=5.0, and magnetically stir for 2 hours to fully hydrolyze and condense the methoxy group on the mercaptosilane coupling agent KH-590 to obtain a mixed suspension; wherein, the cellulose nanowire and silane The mass ratio of coupling agent KH-590 is 1:1.

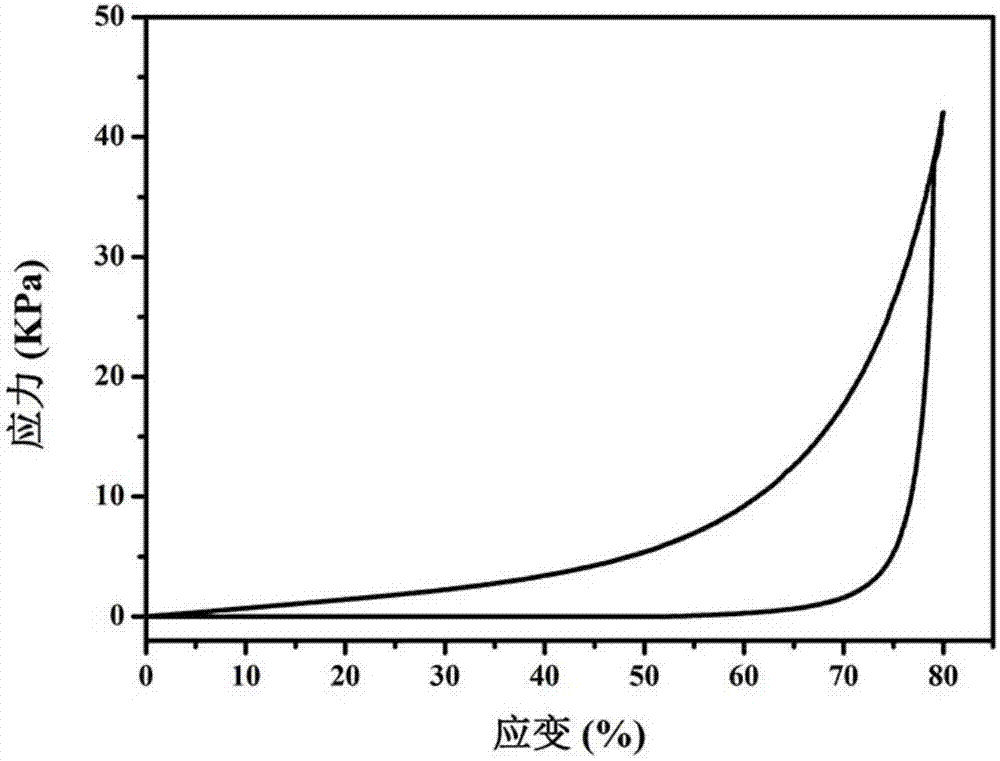

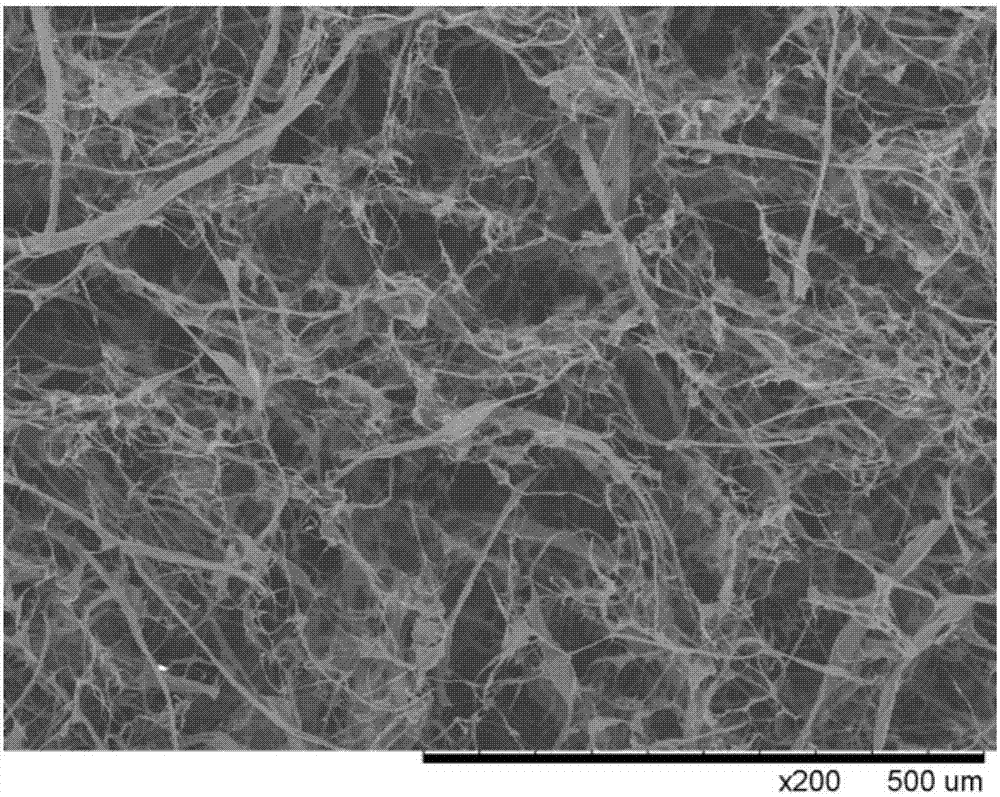

[0029] (2) Put the mixed suspension prepared in (1) into liquid nitrogen for rapid freezing to obtain a frozen gel, put it into a freeze dryer for freeze drying, and place it in an oven at 105°C for 30 minutes to solidify after drying to increase the mercapto group The degree of cross-linking between the silane coupling agent and cellulose was obtained to obtain a porous material of mercaptocellulose, and the measured specific surface area was 7....

Embodiment 2

[0031] (1) Weigh 10g of 0.6wt% carboxylated cellulose nanowire suspension, the diameter of the cellulose nanowire is 1-200nm, and the length is 50-700nm; add mercaptosilane coupling agent KH-590 to the cellulose nanowire In the suspension, adjust the pH to 5.0 with hydrochloric acid at room temperature, and stir magnetically for 2 hours to fully hydrolyze and condense the methoxy group on the mercaptosilane coupling agent KH-590 to obtain a mixed suspension; wherein, the carboxylated cellulose nanowire The mass ratio of mercaptosilane coupling agent KH-590 is 1:2.

[0032] (2) Put the mixed suspension prepared in (1) into liquid nitrogen for rapid freezing to obtain a frozen gel, put it into a freeze dryer for freeze drying, and place it in an oven at 110°C for 30 minutes to solidify after drying to increase the mercapto group The degree of cross-linking between the silane coupling agent and cellulose is obtained to obtain a porous material of mercaptocellulose, and the measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com