Metal hydroxide hollow nanotube, preparation method thereof and application thereof

A technology of hydroxide and nanotubes, which is applied in the field of nanomaterials, can solve problems such as poor thermal stability, material agglomeration, and one-dimensional structure collapse, and achieve the effects of low reaction cost, high product purity, and high specific capacitance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

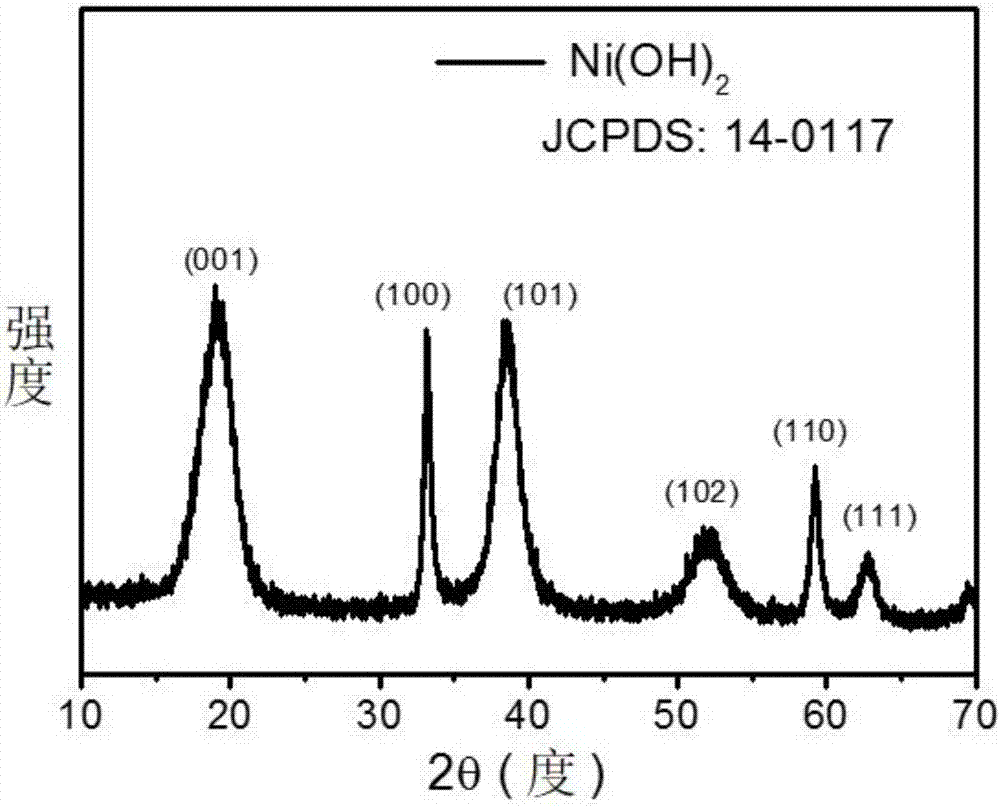

[0042] The invention provides a method for preparing metal hydroxide hollow nanotubes, comprising the following steps:

[0043] A) using tellurium nanowires as templates and carbohydrates as carbon sources to obtain carbon nanofibers through hydrothermal carbonization;

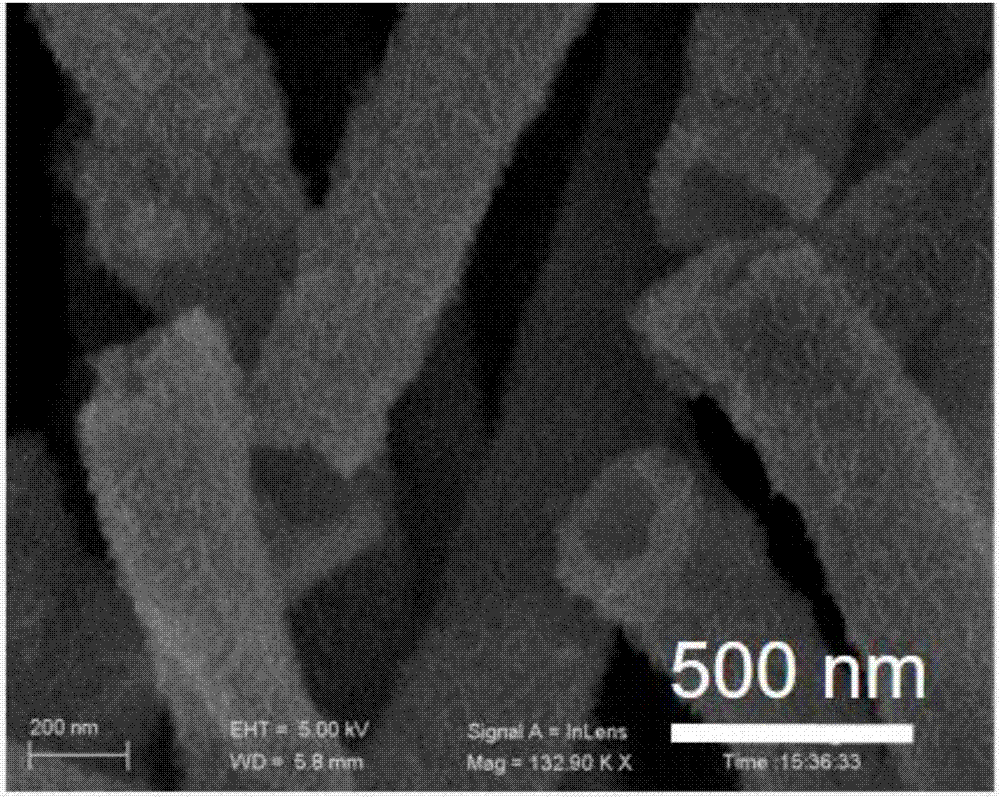

[0044] B) mixing the carbon nanofibers with the metal salt precursor and heating the reaction in an oil bath to obtain carbon nanofibers coated with the metal salt precursor;

[0045] C) performing alkaline etching on the carbon nanofibers coated with the metal salt precursor to obtain metal hydroxide hollow nanotubes.

[0046] The invention can prepare metal hydroxide hollow nanotubes, the method is simple and practical, and easy to be popularized on a large scale. Moreover, the metal hydroxide hollow nanotube has excellent electrochemical performance and has a good application prospect.

[0047] In the embodiment of the present invention, carbon nanofiber templates are first prepared: ultrafine tellurium n...

Embodiment 1

[0072] (1) Preparation of carbon nanofibers: Add 10g of polyvinylpyrrolidone and 920mg of sodium tellurite into 320mL of water, stir well, then add 33.3mL of ammonia water and 16.7mL of hydrazine hydrate, stir well and transfer to 500mL of polytetrafluoroethylene In an ethylene reactor, react in an oven at 180° C. for 3 hours to obtain a tellurium nanowire dispersion. Wherein, the diameter of the tellurium nanowire is 7nm.

[0073] 10 mL of the tellurium nanowire dispersion was added to 30 mL of acetone, and centrifuged at a centrifugal speed of 8000 rpm for 4 minutes to obtain a tellurium nanowire precipitate. Then, the tellurium nanowire precipitate was dispersed in 80 mL of water, 5 g of glucose was added, transferred to a 100 mL polytetrafluoroethylene reactor, and reacted in an oven at 180 ° C for 18 h to obtain a carbon nanofiber hydrogel. The carbon nanofiber hydrogel was centrifuged and washed with ethanol, and dried in a vacuum oven at 60° C. for 12 hours to obtain 2...

Embodiment 2

[0078] Metal hydroxide nanotubes were prepared according to the method in Example 1, with the following differences: the alkali etching time was 2 hours.

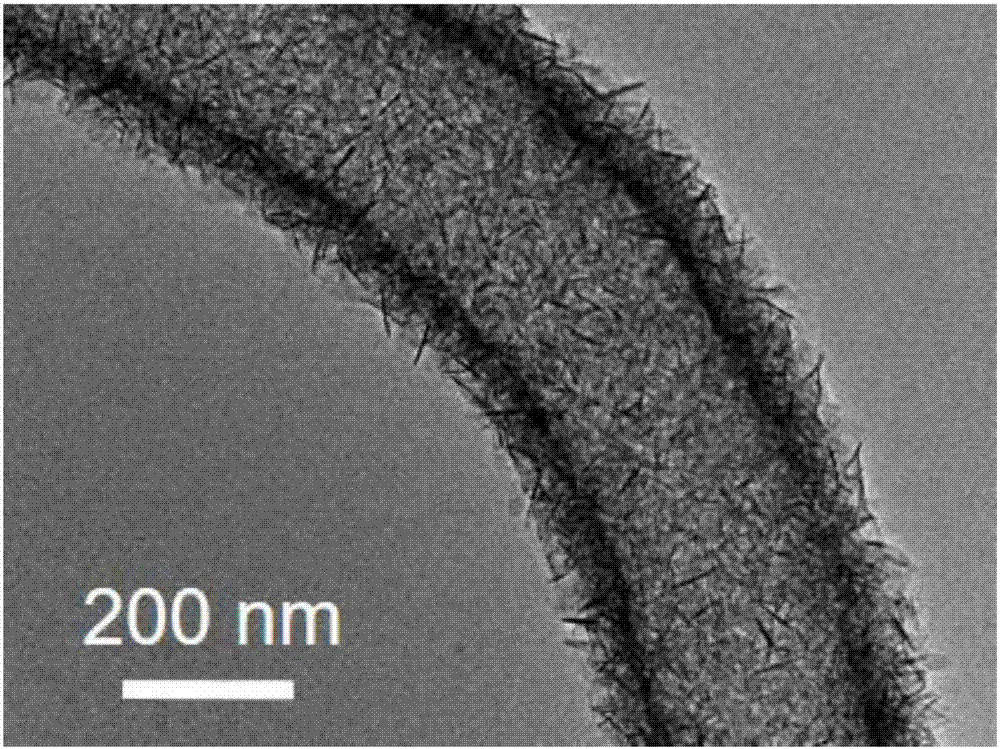

[0079] Gained product is carried out transmission electron microscope analysis, the result sees Figure 5 . Compared with Example 1, it is found that the carbon nanofiber template in the middle is not completely etched, and some parts remain, which is a semi-hollow structure, and the diameter of the hollow part is about 150 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com