High-strength white concrete and preparation method thereof

A concrete and high-strength technology, applied in the field of building materials, can solve the problems of white concrete carbonation, yellowing and discoloration, white concrete corrosion, building snow and freezing, etc., to achieve the effect of preventing corrosion and discoloration, reducing carbonization, and degrading pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

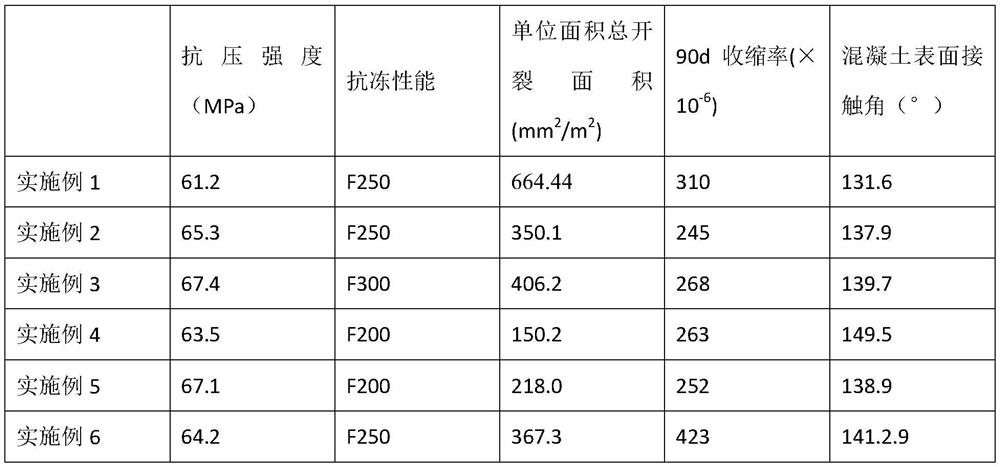

Examples

Embodiment 1

[0035] Example 1: A high-strength white concrete, calculated in parts by weight, comprising the following components: 70-100 parts of white Portland cement, 10-30 parts of white mineral powder, 10-30 parts of white limestone powder, metakaolin 5-15 parts, 5-10 parts of titanium dioxide, 100-200 parts of river sand, 120-150 parts of light-colored aggregate, 35-50 parts of water, 1-3 parts of water reducing agent, 0.2-0.5 parts of retarder, 5-10 parts of carbon quantum dots and 5-8 parts of sodium chloropalladate.

[0036] A preparation method for high-strength white concrete, comprising the following steps:

[0037] S1. Mix 70-100 parts of white Portland cement, 10-30 parts of white mineral powder, 10-30 parts of white limestone powder, 5-15 parts of metakaolin, 5-10 parts of titanium dioxide and 35-50 parts of water , stirred for 5-7h to obtain mixture A;

[0038] S2. Add 5 to 10 parts of carbon quantum dots and 5 to 8 parts of sodium chloropalladate to mixture A, and stir f...

Embodiment 2

[0040] Embodiment 2: A kind of high-strength white concrete, calculated according to parts by weight, includes the following components: 100 parts of white Portland cement, 30 parts of white mineral powder, 30 parts of white limestone powder, 5 parts of metakaolin, 5 parts of titanium dioxide 200 parts of river sand, 150 parts of light-colored aggregate, 50 parts of water, 1 part of water reducer, 0.2 parts of retarder, 5 parts of carbon quantum dots, 8 parts of sodium chloropalladate and 5 parts of polysilazane.

[0041] Its preparation method is as follows:

[0042] S1. Stir 100 parts of white Portland cement, 30 parts of white mineral powder, 30 parts of white limestone powder, 5 parts of metakaolin, 5 parts of titanium dioxide and 50 parts of water, and stir for 5-7 hours to obtain mixture A;

[0043] S2. Add 5 parts of carbon quantum dots and 8 parts of sodium chloropalladate to mixture A, and stir for 1 to 3 hours to obtain mixture B;

[0044] S3. Add 200 parts of river...

Embodiment 3

[0045] Embodiment 3: A kind of high-strength white concrete, according to the technology of parts by weight, comprises the following components: 100 parts of white Portland cement, 30 parts of white mineral powder, 30 parts of white limestone powder, 5 parts of metakaolin, 5 parts of titanium dioxide 200 parts of river sand, 150 parts of light-colored aggregate, 50 parts of water, 1 part of water reducer, 0.2 parts of retarder, 5 parts of carbon quantum dots, 8 parts of sodium chloropalladate and 5 parts of polysilazane.

[0046] Its preparation method is as follows:

[0047] S1. Stir 100 parts of white Portland cement, 30 parts of white mineral powder, 30 parts of white limestone powder, 5 parts of metakaolin, 5 parts of titanium dioxide and 50 parts of water, and stir for 5-7 hours to obtain mixture A;

[0048] S2. Add 5 parts of carbon quantum dots and 8 parts of sodium chloropalladate to mixture A, and stir for 1 to 3 hours to obtain mixture B;

[0049] S3. Add 200 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com