Double-injection gas valve

A technology of injecting gas and valve core, which is applied in the direction of multi-way valves, valve devices, valve details, etc., can solve the problems of unfavorable gas source replacement, unfavorable promotion and application of new gas sources, and increased replacement costs, so as to achieve humanized operation and reduce Effect of small volume and reduced risk of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

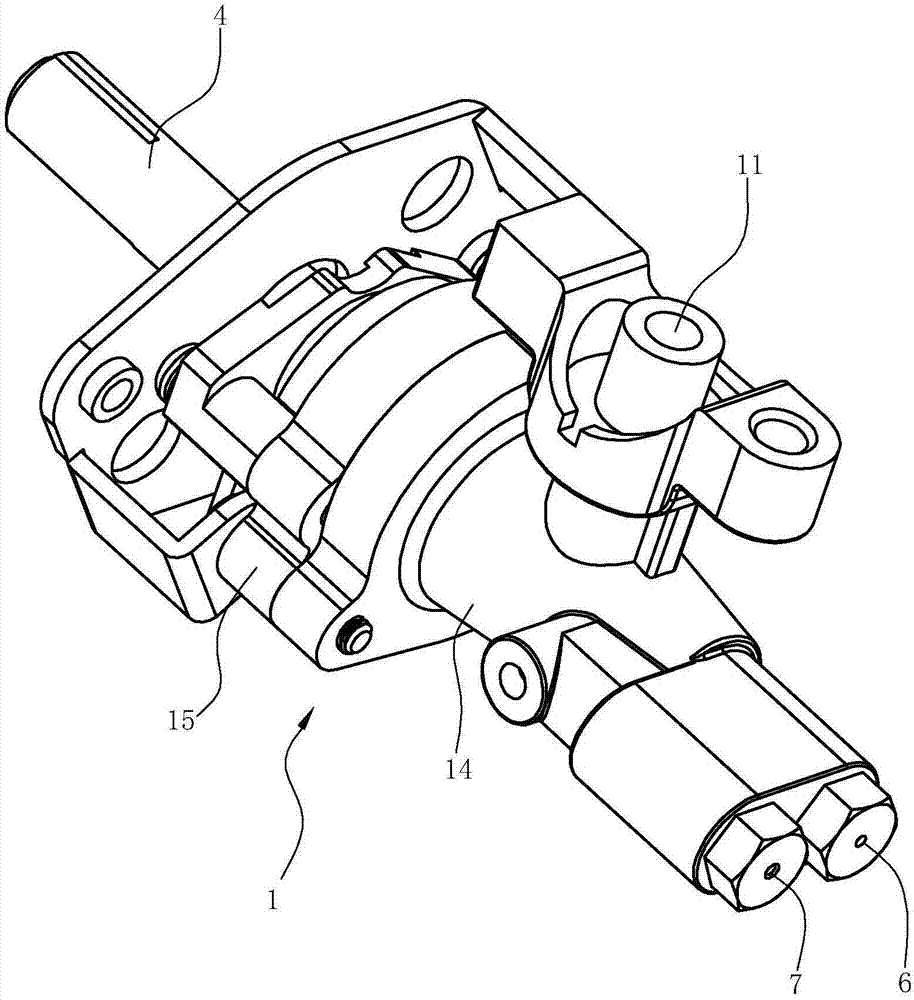

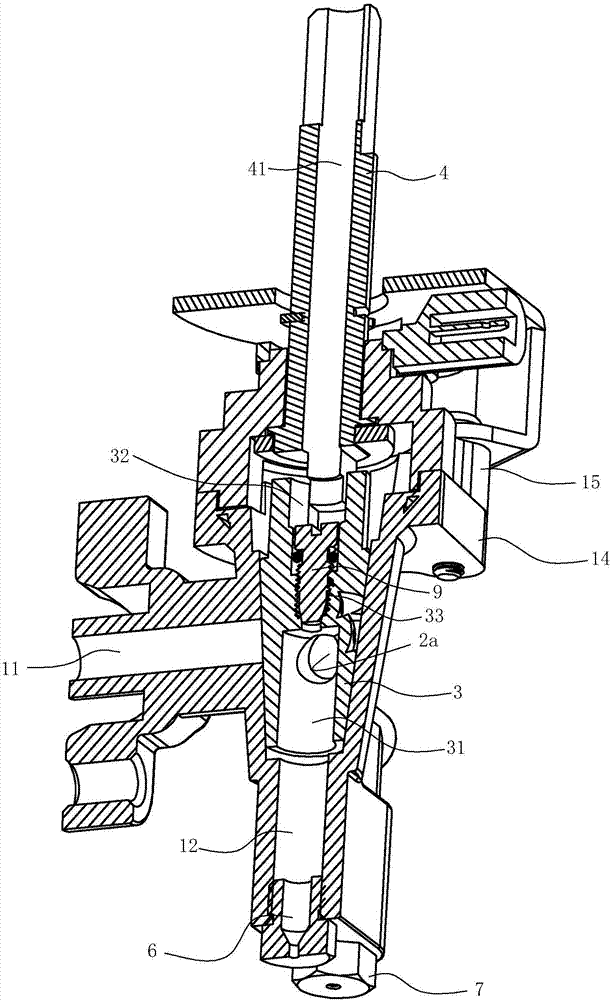

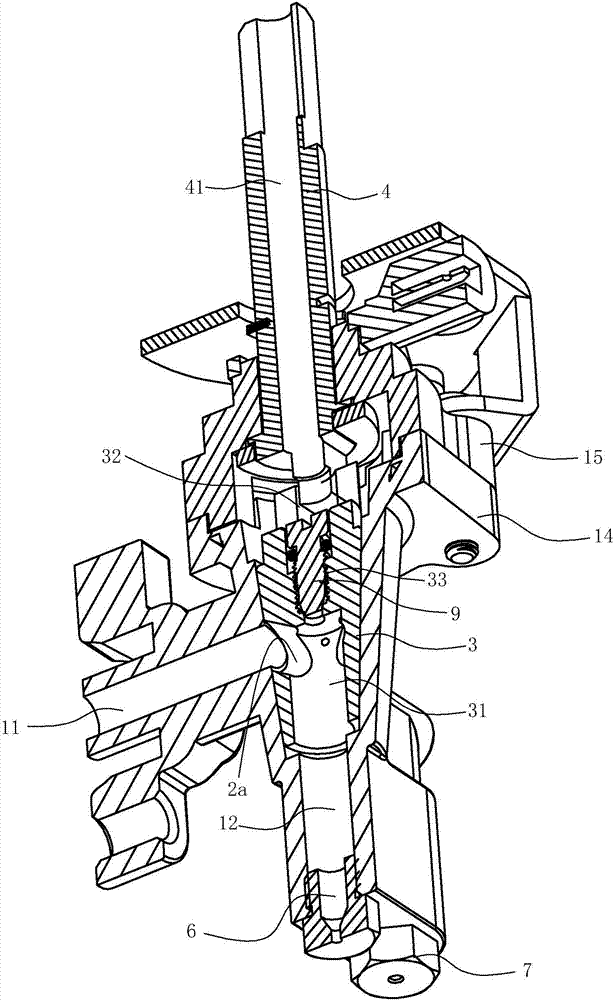

[0035] Such as Figure 1-11 Shown is a preferred embodiment of the invention.

[0036] A double-jet gas valve, comprising a valve body 1 having an air inlet passage 11 and a main outlet passage 12, a rotatable valve core 3 is arranged inside the valve body 1, and the upper part of the valve core 1 is provided with an opening facing upward for the valve stem 4 connected to the connection cavity 32, the lower part of the valve core 3 is provided with a ventilation cavity 31 with an opening facing downwards, and the side wall of the ventilation cavity 31 of the valve core is provided with a first large fire hole 2a for communicating with the intake passage 11 and the main outlet passage 12 and The small fire hole 5, the gas outlet end of the main gas outlet channel 12 is equipped with a main nozzle 6. The above are conventional designs for gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com