Anti-grout-leakage prefabricated type connecting structure for steel structure building

A connection structure and anti-leakage slurry technology, which is applied in the direction of building construction and construction, can solve the problems of inability to finely prefabricate, achieve the effects of improving stability and safety, improving stability and safety, and improving support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

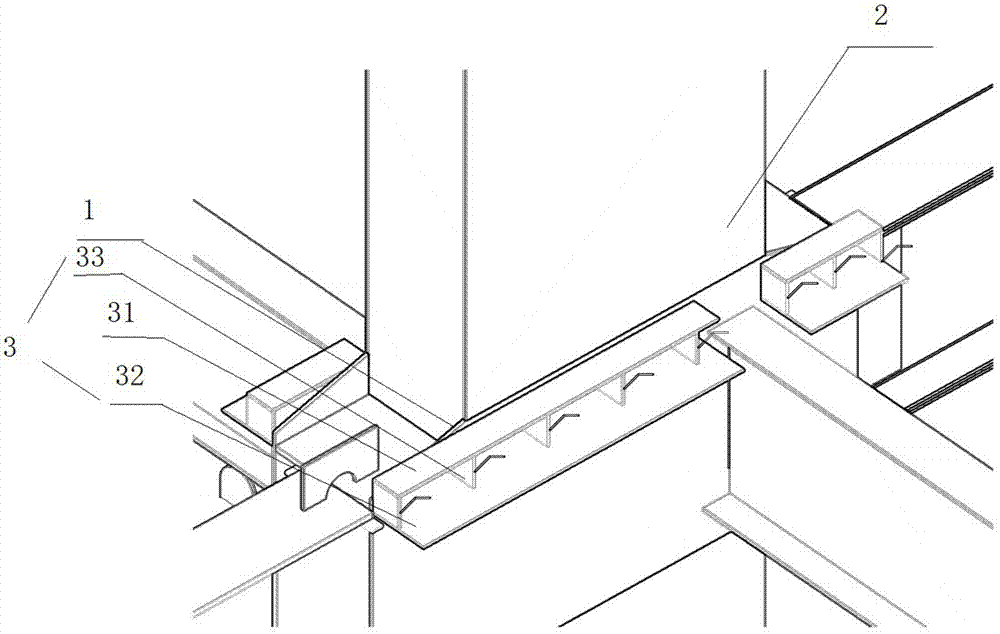

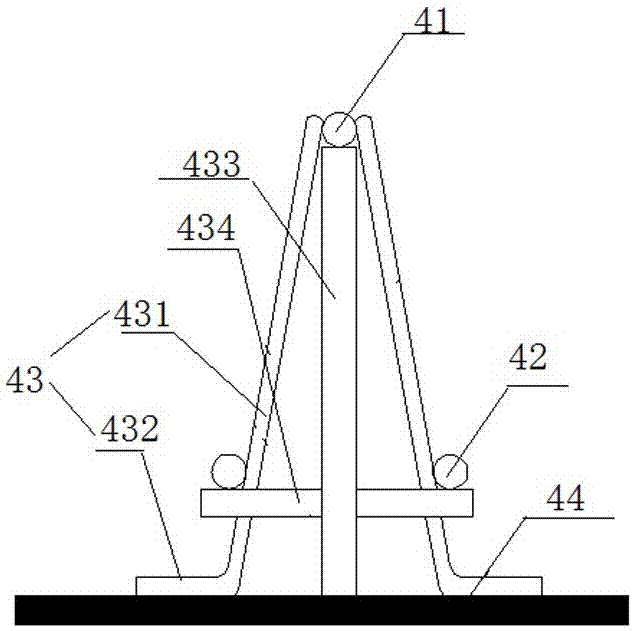

[0032] As shown in the figure, a prefabricated connection structure for anti-leakage slurry in steel structure buildings includes: floor deck 1, wall body 2 and steel bar truss 4, wherein the floor deck 1 is connected to wall body 2 There is a connection pallet 3 at the center, the connection pallet 3 is composed of an upper pallet 31 and a lower pallet 32, and the upper pallet 31 and the lower pallet 32 are relatively arranged on the connection between the floor deck 1 and the wall 2 , and a stiffening plate 33 is provided between the upper pallet 31 and the lower pallet 32 , and the steel bar truss 4 is arranged on the connecting pallet 3 .

[0033] In this embodiment, the supporting plate 3 is placed on the connection between the floor deck 1 and the wall 2 , and the connecting plate 3 and the floor deck 1 and the wall 2 are connected by steel joints.

[0034] In this embodiment, the supporting plate 3 is placed on the connection between the floor deck 1 and the wall 2 ...

Embodiment 2

[0042] As shown in the figure, a prefabricated connection structure for anti-leakage slurry in steel structure buildings includes: floor deck 1, wall body 2 and steel bar truss 4, wherein the floor deck 1 is connected to wall body 2 There is a connection pallet 3 at the center, the connection pallet 3 is composed of an upper pallet 31 and a lower pallet 32, and the upper pallet 31 and the lower pallet 32 are relatively arranged on the connection between the floor deck 1 and the wall 2 , and a stiffening plate 33 is provided between the upper pallet 31 and the lower pallet 32 , and the steel bar truss 4 is arranged on the connecting pallet 3 .

[0043] In this embodiment, the supporting plate 3 is placed on the connection between the floor deck 1 and the wall 2 , and the connecting plate 3 and the floor deck 1 and the wall 2 are connected by steel joints.

[0044] In this embodiment, the supporting plate 3 is placed on the connection between the floor deck 1 and the wall 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com