Novel electric flocculation device and method

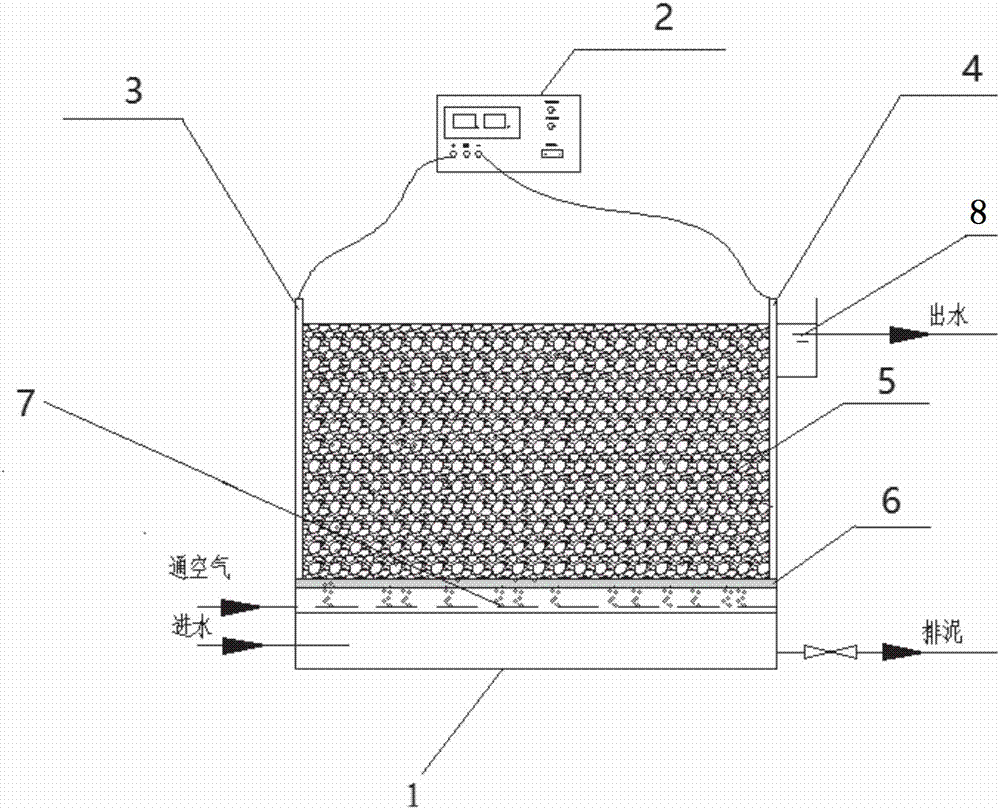

A new type of electro-flocculation technology, applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage treatment, etc., can solve the problems of passivation, replacement of the electrode plate to increase the workload, and the electrode plate cannot be fully used, etc., to achieve full response Time, electrochemical reaction speed, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

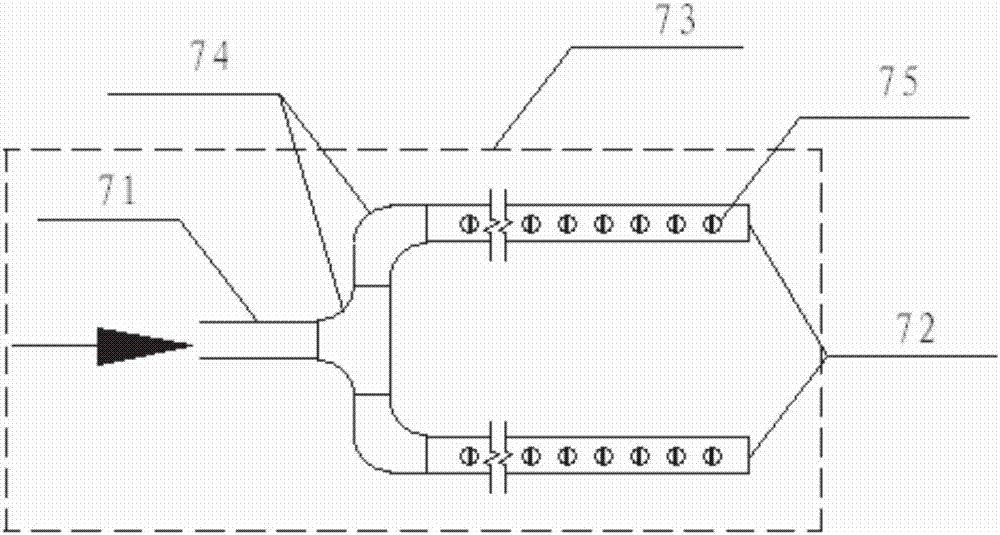

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: process electroless plating nickel-containing waste water

[0029] The iron-carbon micro-electrolytic packing bed is used as the cation donor, the iron-carbon ratio is 5:5, the bed layer is stacked in a rectangular shape, the filling length is 800mm, and the height is 600mm. Graphite is used as the plate, and the DC power supply is supplied at a voltage of 80V. Microporous aeration, the volume flow ratio of gas to water is 1:9, the treatment time of electroless nickel-containing wastewater is 30 minutes, and the COD after treatment Cr From 1050mg / L to 300mg / L, Ni 2 + From 96.5mg / L to 10.3mg / L, total phosphorus from 580mg / L to 95.7mg / L, ammonia nitrogen from 175mg / L to 37.8mg / L.

Embodiment 2

[0030] Embodiment 2: process electroless plating nickel-containing waste water

[0031] The aluminum-carbon micro-electrolytic packing bed is used as the cation donor, the aluminum-carbon ratio is 6:5, the bed layer is stacked in a rectangular shape, the packing length is 1000mm, and the height is 800mm. Graphite is used as the plate, and the DC power supply is powered by a voltage of 120V. Microporous aeration, the air-to-water ratio is 10:1, the treatment time of electroless nickel-containing wastewater is 20 minutes, and the COD after treatment Cr From 1050mg / L to 160mg / L, Ni 2+ From 96.5mg / L to 0.8mg / L, total phosphorus from 580mg / L to 10.1mg / L, ammonia nitrogen from 175mg / L to 20.3mg / L.

Embodiment 3

[0032] Embodiment 3: process electroless plating nickel-containing waste water

[0033] The iron-carbon micro-electrolytic packing bed is used as the cation donor, the iron-carbon ratio is 7:5, the bed layer is stacked in a rectangular shape, the filling length is 600mm, and the height is 600mm. Graphite is used as the plate, and the DC power supply is powered by a voltage of 110V. Microporous aeration, the air-to-water ratio is 2:7, the treatment time of electroless nickel-containing wastewater is 10 minutes, and the COD after treatment Cr From 1050mg / L to 100mg / L, Ni 2+ From 96.5mg / L to 0.1mg / L, total phosphorus from 580mg / L to 1.1mg / L, ammonia nitrogen from 175mg / L to 17.9mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com