Preparation method of graphene quantum dot dispersion liquid

A technology of graphene quantum dots and dispersion liquid, applied in the field of material science, can solve the problems of introducing wrinkles, holes, graphene mechanical properties, and electrical properties into graphene, and achieves the effects of being suitable for promotion, environment-friendly, and efficient in preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

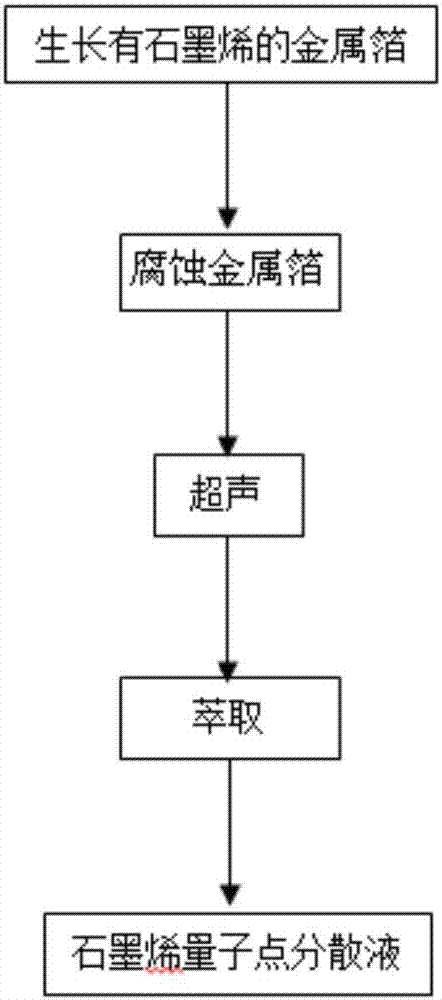

[0020] The specific steps of the preparation method of the graphene quantum dot involved in the present embodiment are:

[0021] (1) Put a 1cm×1cm or 2cm×2cm copper foil with graphene film grown in 20-80mL ammonium persulfate (0.05-0.5M) corrosion solution for 3-8h to remove the copper foil and obtain graphene-containing Thin film corrosion solution;

[0022] (2) Ultrasonic treatment (power 50-200W) of the corrosion solution containing graphene film obtained in step (1) for 10-150min, and then extracted with dichloromethane to obtain graphene quantum dot dispersion.

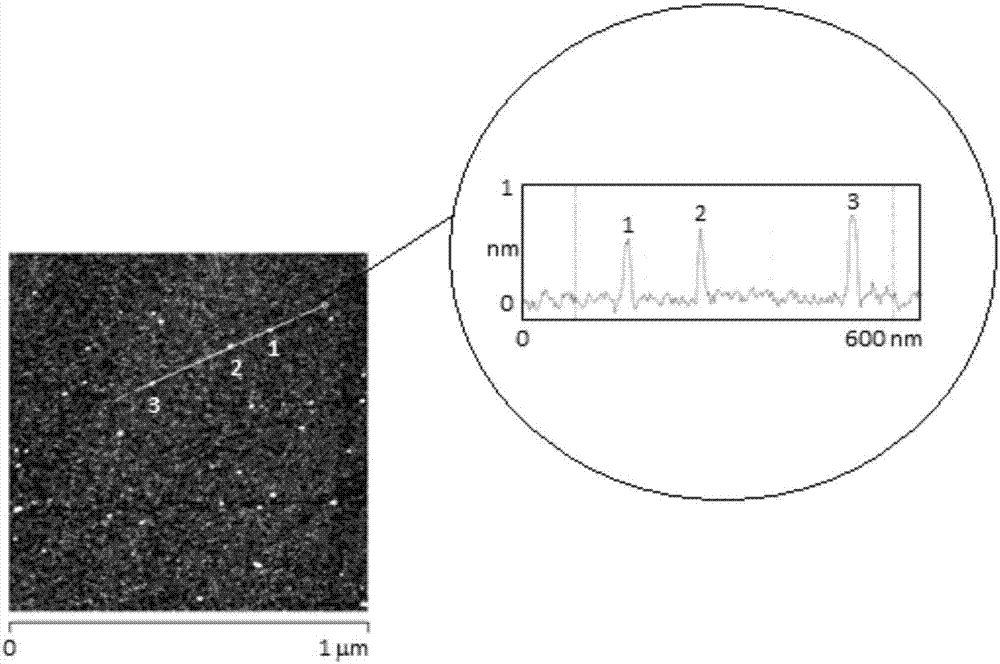

[0023] The graphene quantum dot dispersion liquid prepared in the present embodiment is photographed under natural light (such as figure 2 Shown) fluorescence is good; Among them, the atomic force microscope scanning image of graphene quantum dots (such as image 3 shown) and the height distribution map (as Figure 4 shown).

Embodiment 2

[0025] The specific steps of the preparation method of the graphene quantum dot involved in the present embodiment are:

[0026] (1) Graphene prepared by chemical vapor deposition is used as raw material, and 2-20cm 2 The metal foil with the graphene film grown is put into 20-200mL ferric nitrate (0.1-0.5g / ml) solution and corroded for 2-10h to remove the metal foil to obtain an etching solution containing the graphene film;

[0027] (2) Ultrasonic treatment (power 50-200W) of the corrosion solution containing the graphene film obtained in step (1) for 10-150 min, and then extracted with chloroform to obtain the graphene quantum dot dispersion.

[0028] The graphene quantum dot dispersion liquid prepared in the present embodiment is photographed under 365nm ultraviolet light (such as Figure 5 Shown); wherein the transmission electron microscope image of graphene quantum dots (such as Figure 6 shown), high-resolution transmission electron microscope images (such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com