Preparation and application methods for magnetic core-shell nano composite adsorbent

A nano-composite, adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, silicon compounds, etc., can solve the limitation of adsorbent recovery, regeneration and recycling, reduction of adsorbent specific surface area, and reduced adsorption capacity, etc. problems, to achieve the effects of good environmental and economic benefits, excellent adsorption performance, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

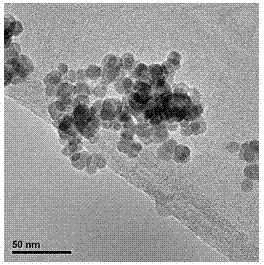

[0024] Embodiment 1 A magnetic core-shell Fe 3 o 4 @SiO 2 @CeO 2 Preparation method of nanocomposite adsorbent

[0025] 1) Magnetic Fe 3 o 4 Preparation of nanoparticles: weigh 2.7g FeCl 3 ·6H 2 O and 1.2 g FeCl 2 ∙4H 2 O, dissolve it in 20ml deionized water to prepare Fe 3+ and Fe 2+ Mix the solution; measure 5ml of ammonia water with a mass concentration of 25-28%, and add it to 50ml of deionized water to make a mother liquor; feed nitrogen into the mother liquor and start a mechanical stirring device, and drop Fe into the mother liquor under stirring conditions 3+ and Fe 2+ Mix the solution, react at 80°C for 60 minutes, then add 4g of sodium citrate to react for 60 minutes, cool to room temperature naturally, pour off the supernatant after magnetic separation, collect the black sediment, wash with distilled water until neutral, and then wash with 90ml of absolute ethanol Wash three times and dry in a vacuum oven at 50°C for 12 hours to obtain sodium citrate-mod...

Embodiment approach 2

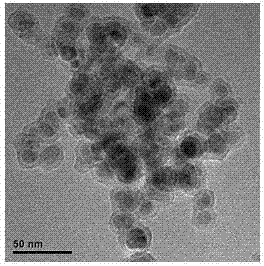

[0029] Embodiment 2 A magnetic core-shell Fe 3 o 4 @SiO 2 @CeO 2 Preparation method of nanocomposite adsorbent

[0030] 1) Magnetic Fe 3 o 4 Preparation of nanoparticles: weigh 5.4g FeCl 3 ·6H 2 O and 2.4 g FeCl 2 ∙4H 2 O, dissolve it in 40ml deionized water to prepare Fe 3+ and Fe 2+ Mix the solution; measure 10ml of ammonia water with a mass concentration of 25-28%, and add it to 50ml of deionized water to make a mother liquor; feed nitrogen into the mother liquor and start a mechanical stirring device, and drop Fe into the mother liquor under stirring conditions 3+ and Fe 2+ Mix the solution, react at 90°C for 60 minutes, then add 8g of sodium citrate to react for 90 minutes, naturally cool to room temperature, pour off the supernatant after magnetic separation, collect the black sediment, wash with distilled water until neutral, and then wash with 90ml of absolute ethanol Wash three times and dry in a vacuum oven at 50°C for 18 hours to obtain sodium citrate-mo...

Embodiment approach 3

[0033] Embodiment 3 A magnetic core-shell Fe 3 o 4 @SiO 2 @CeO 2 Preparation method of nanocomposite adsorbent

[0034] 1) Magnetic Fe 3 o 4 Preparation of nanoparticles: weigh 1.8g FeCl 3 ·6H 2 O and 1.6 g FeCl 2 ∙4H 2 O, dissolve it in 15ml deionized water to prepare Fe 3+ and Fe 2+ Mix the solution; measure 4ml of ammonia water with a mass concentration of 25-28%, and add it to 50ml of deionized water to make a mother liquor; feed nitrogen into the mother liquor and start a mechanical stirring device, and drop Fe into the mother liquor under stirring conditions 3+ and Fe 2+ Mix the solution, react at 80°C for 60 minutes, then add 3g of sodium citrate to react for 60 minutes, naturally cool to room temperature, pour off the supernatant after magnetic separation, collect the black sediment, wash with distilled water until neutral, and then wash with 90ml of absolute ethanol Wash three times and dry in a vacuum oven at 50°C for 10 hours to obtain sodium citrate-mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com