Preparation method of underwater ultraoleophobic and under-oil ultrahydrophobic membrane, and method of continuously separating light-oil/water/heavy-oil mixture therewith

A technology for underwater super-oleophobic and heavy oil mixtures, which is applied in semi-permeable membrane separation, chemical instruments and methods, and liquid separation. It can solve the problems of poor chemical stability, expensive preparation costs, and unfavorable industrial production. Raw materials are easily available and the production cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

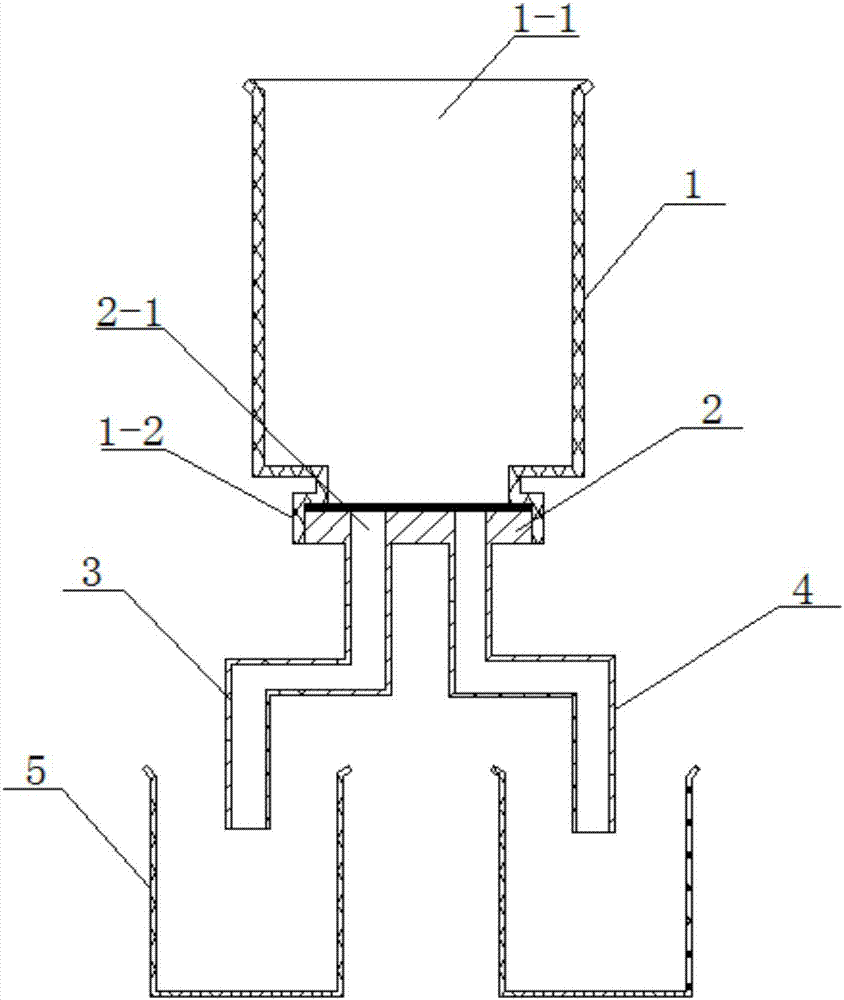

[0049] Specific embodiment one: the preparation method of a kind of underwater super oleophobic and oil super hydrophobic film described in this embodiment is carried out according to the following steps:

[0050] 1. Preparation of mesh substrate:

[0051] Select a mesh filter base, the mesh number of the mesh filter base is not more than 800 mesh;

[0052] 2. Preparation of coating dispersion:

[0053] Mix biomass powder, water-based polyurethane and absolute ethanol to obtain a coating dispersion;

[0054] The mass ratio of the biomass powder to absolute ethanol is (0.001~1):1; the mass ratio of the water-based polyurethane to absolute ethanol is (0.0001~100):1;

[0055] 3. Spraying:

[0056] The spraying amount is (0.1~100)g / cm 3 Under certain conditions, the coating dispersion is evenly sprayed on the mesh filter substrate to obtain underwater super-oleophobic and sub-oil super-hydrophobic films.

[0057] The beneficial effects of this embodiment are: 1. The method of...

specific Embodiment approach 2

[0062] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mesh filter base described in step 1 is nylon mesh, steel mesh, copper mesh, cotton cloth or non-woven fabric. Others are the same as in the first embodiment.

specific Embodiment approach 3

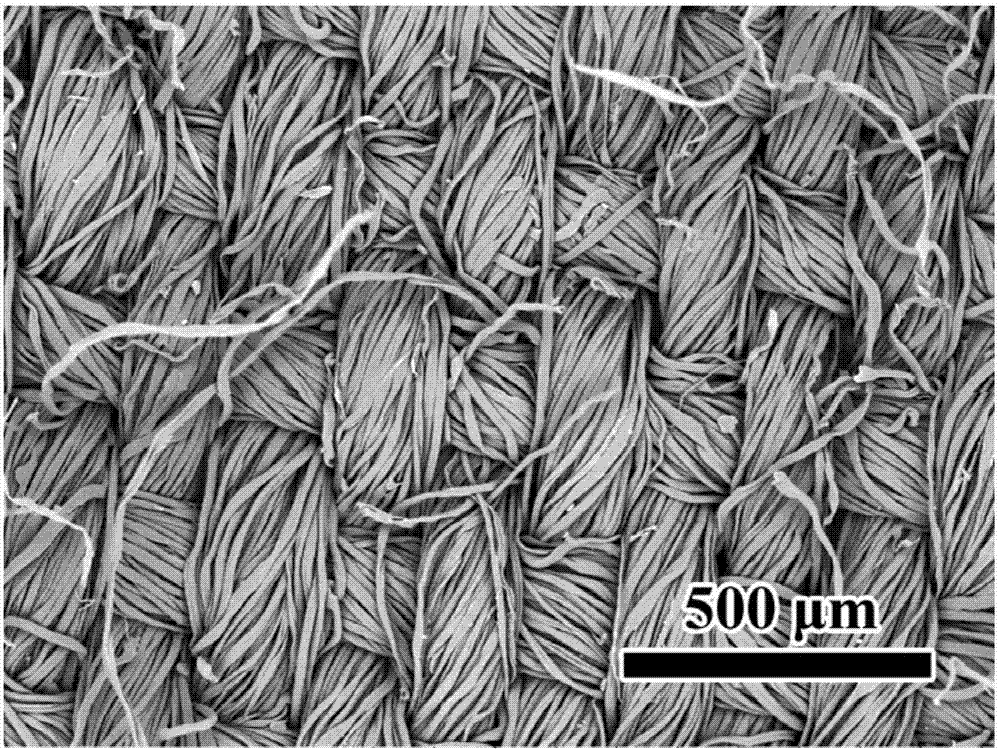

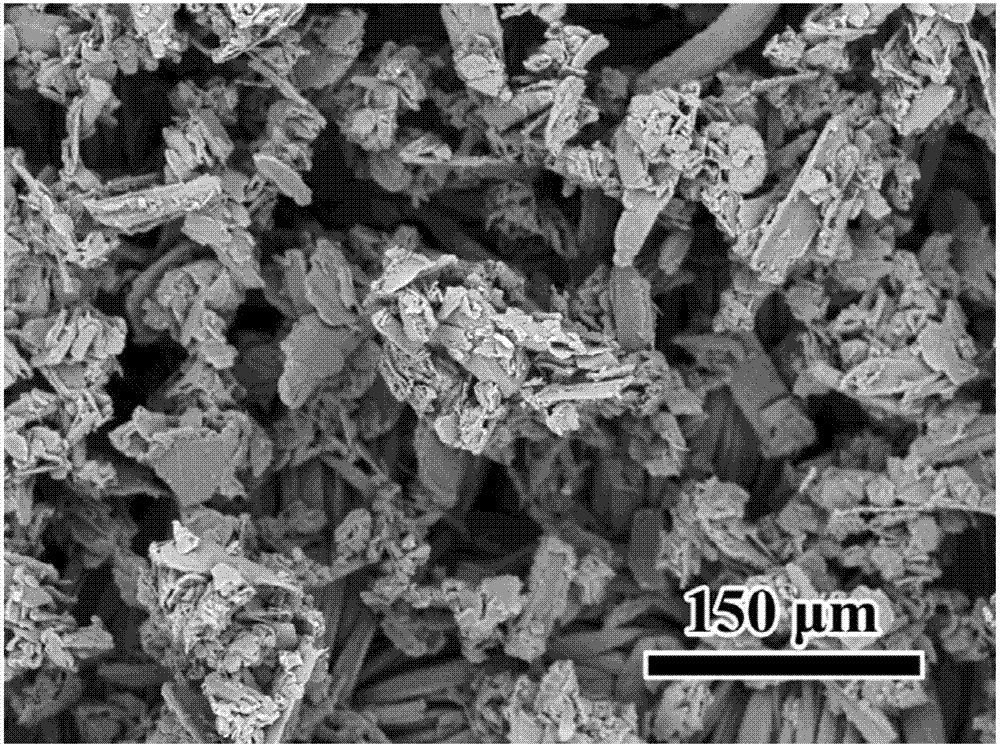

[0063] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the biomass powder described in step two is straw powder, starch, corn flour or microalgae powder; the biomass powder described in step two The mesh number of the substance powder is 200 mesh to 800 mesh. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com