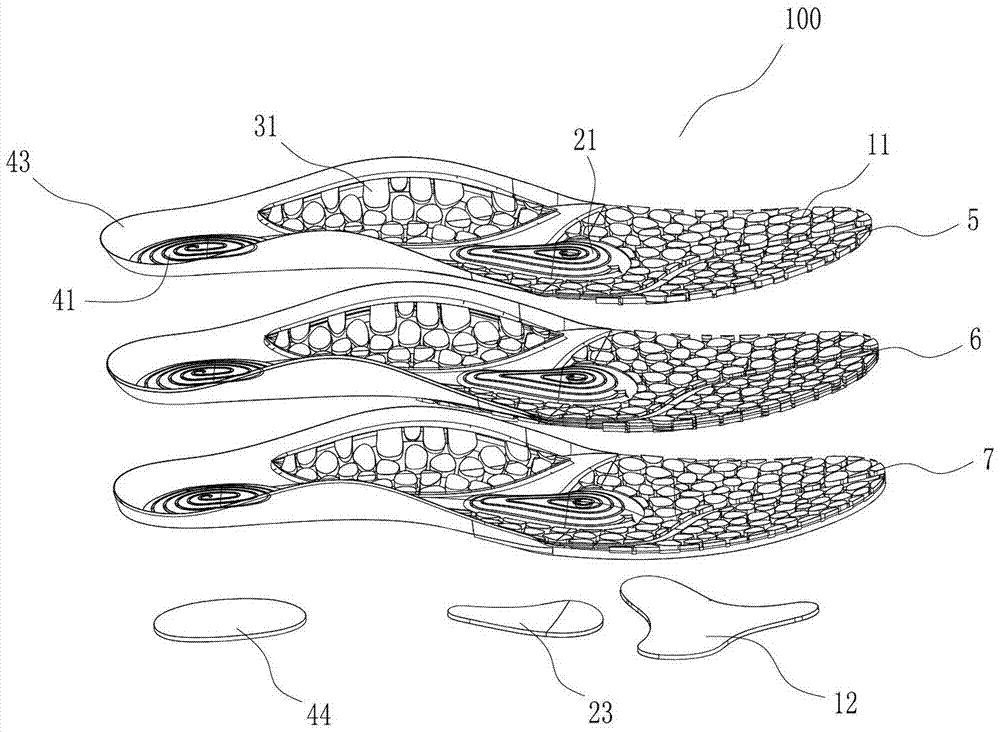

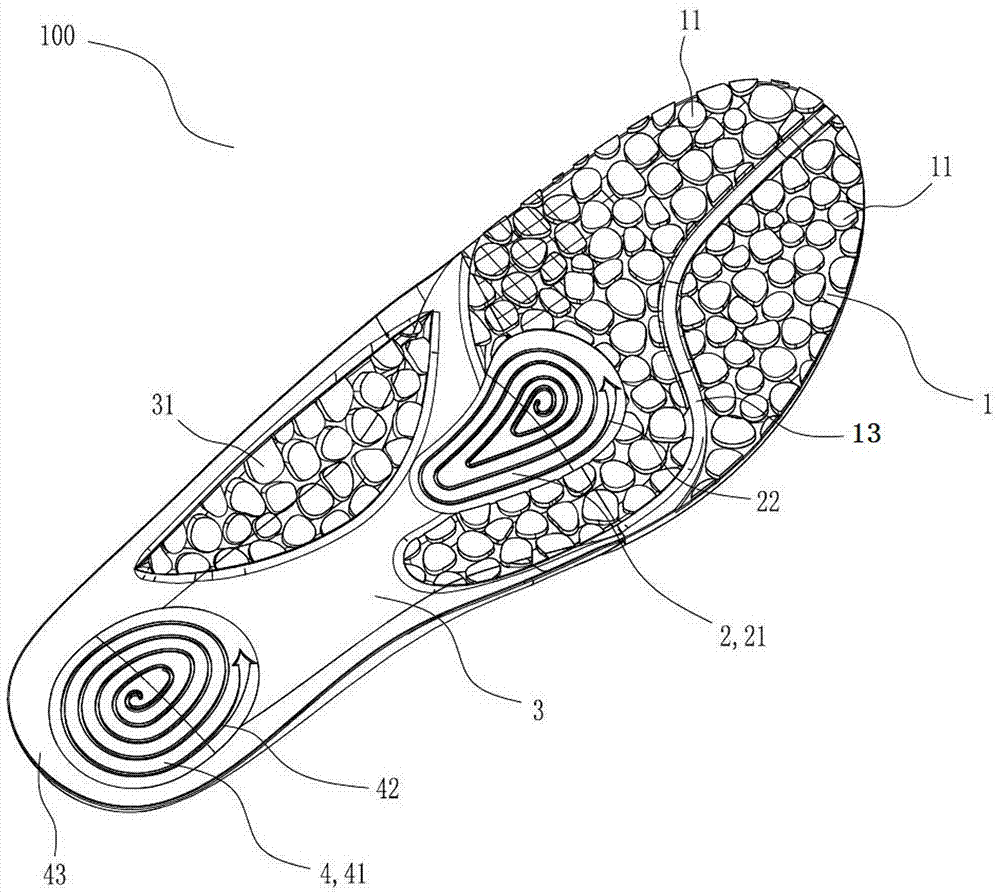

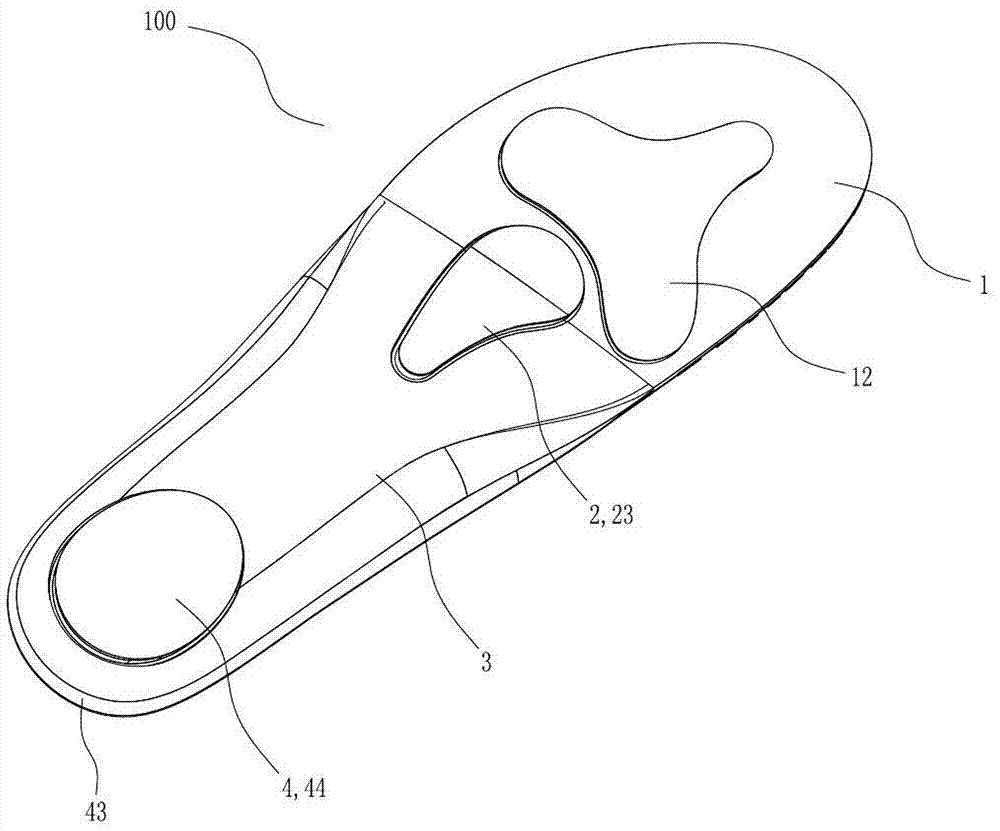

Insole special for old people

A technology for the elderly and insoles, which is applied in the field of special insoles for the elderly. It can solve the problems that it is difficult to protect the plantar bones, ankle joints and knee joints, it is not conducive to toe extension, grip, and does not have the function of massage and health care, so as to achieve the purpose of promoting foot care. Blood circulation, reduce the risk of accidental injury, the effect of relieving foot fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Memory foam is made of the following raw materials: polyether polyol 10kg, diphenylmethane diisocyanate 0.5kg, gardenia pollen 0.2kg, isophorone diisocyanate 1kg, water 0.2kg, silicone oil 0.1kg, Catalyst 0.05kg, blowing agent 0.08kg, crosslinking agent 0.3kg.

[0042] The preparation method is as follows: add polyether polyol, diphenylmethane diisocyanate, gardenia pollen and isophorone diisocyanate into a mixer in corresponding parts by weight, stir evenly, heat up to 35-38 degrees Celsius, and mix corresponding parts Add several other raw materials into the mixer, stir at high speed for 6-8 seconds, pour into the mold to foam and solidify, and obtain the corresponding memory foam layer.

[0043] The bamboo charcoal fiber layer is composed of bamboo charcoal fiber, nano-silver fiber, single crystal sapphire whisker and viscose fiber; the viscose fiber contains 0.8% ceramic powder and a coupling agent, and the coupling agent is 0.1% of the weight of the ceramic powder;...

Embodiment 2

[0051] Memory foam is made of the following raw materials: polyether polyol 10kg, diphenylmethane diisocyanate 1kg, gardenia pollen 0.1kg, isophorone diisocyanate 0.5kg, water 0.2kg, silicone oil 0.1kg, Catalyst 0.05kg, blowing agent 0.08kg, crosslinking agent 0.3kg.

[0052] The preparation method of the memory foam layer is as follows: add polyether polyol, diphenylmethane diisocyanate, gardenia pollen and isophorone diisocyanate into a mixer in corresponding parts by weight and stir evenly, heat up to 35-38 Celsius, add corresponding parts of other raw materials into the mixer, stir at high speed for 6-8 seconds, then pour into the mold to foam and solidify to obtain the corresponding memory foam layer.

[0053] The bamboo charcoal fiber layer is composed of bamboo charcoal fiber, nano silver fiber, single crystal sapphire whisker and viscose fiber; viscose fiber contains 0.8-1% ceramic powder and coupling agent, and the coupling agent is 0.2% of the weight of ceramic powde...

Embodiment 3

[0061] Memory foam is made of the following raw materials: polyether polyol 10kg, diphenylmethane diisocyanate 0.8kg, gardenia pollen 0.1kg, isophorone diisocyanate 0.8kg, water 0.3kg, silicone oil 0.08kg , catalyst 0.05kg, blowing agent 0.05kg, crosslinking agent 0.5kg.

[0062] The preparation method of the memory foam layer is as follows: add polyether polyol, diphenylmethane diisocyanate, gardenia pollen and isophorone diisocyanate into a mixer in corresponding parts by weight and stir evenly, heat up to 35-38 Celsius, add corresponding parts of other raw materials into the mixer, stir at high speed for 6-8 seconds, then pour into the mold to foam and solidify to obtain the corresponding memory foam layer.

[0063] The bamboo charcoal fiber layer is composed of bamboo charcoal fiber, nano silver fiber, single crystal sapphire whisker and viscose fiber; viscose fiber contains 0.8-1% ceramic powder and coupling agent, and the coupling agent is 0.3% of the weight of ceramic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com