Iron-cobalt-carbon composite oxide, preparation method thereof and metal air battery

A carbon composite and oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of high price, and achieve the effect of low price, favorable for popular use and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

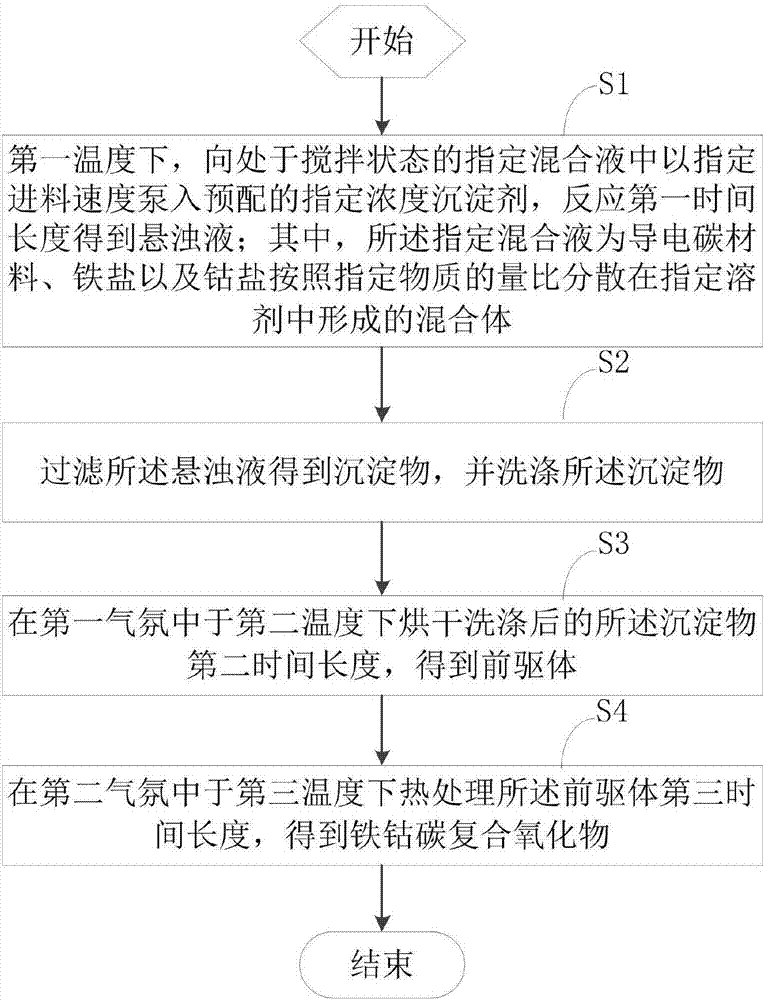

[0024] refer to figure 1 , the embodiment of the present invention proposes a preparation method of iron-cobalt-carbon composite oxide, comprising:

[0025] S1: At the first temperature, pump a pre-prepared precipitant with a specified concentration into the specified mixed solution in a stirring state at a specified feed rate, and react for the first length of time to obtain a suspension; wherein the specified mixed solution is conductive A mixture formed by dispersing carbon materials, iron salts and cobalt salts in a specified solvent according to the specified mass ratio;

[0026] S2: filtering the suspension to obtain a precipitate, and washing the precipitate;

[0027] S3: drying the washed precipitate for a second length of time at a second temperature in a first atmosphere to obtain a precursor;

[0028] S4: heat-treating the precursor at a third temperature for a third time length in a second atmosphere to obtain an iron-cobalt-carbon composite oxide.

[0029] In t...

Embodiment 1

[0042] Disperse conductive carbon black, ferric chloride and cobalt chloride in deionized water according to the ratio of Fe:Co:C substance ratio of 1:1:1, and mix evenly; A good 0.1% sodium hydroxide aqueous solution; after stirring and reacting at 80°C for 2 hours, filter the precipitate obtained from the reaction; after washing the above precipitate, place it in a vacuum oven and dry it under vacuum at 100°C for 12 hours to obtain a precursor; The body was heat-treated at 750°C for 24 hours in a high-purity nitrogen atmosphere, and after cooling in the furnace, an iron-cobalt-carbon composite oxide A with a molar ratio of Fe:Co:C of 1:1:1 was obtained.

Embodiment 2

[0044] Disperse carbon nanotubes, iron nitrate and cobalt nitrate in deionized water according to the ratio of Fe:Co:C substance ratio of 5:9:2, and mix evenly; 16% potassium hydroxide aqueous solution; after stirring and reacting at 65°C for 8 hours, filter the precipitate obtained from the reaction; after washing the above precipitate, place it in a vacuum oven and dry it in a vacuum at 120°C for 8 hours to obtain a precursor; put the above precursor in Under a high-purity argon atmosphere, heat treatment at 800°C for 10 hours, and after cooling in the furnace, an iron-cobalt-carbon composite oxide B with a molar ratio of Fe:Co:C of 5:9:2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com