Preparation method of non deep-fried instant noodles and screw extrusion equipment

A technology of non-fried instant noodles and screw extrusion, which is applied in the directions of food forming, food ingredients as taste improver, food drying, etc. problems such as hidden worries, poor production stability, etc., to ensure uniformity, stable product quality, and fast drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

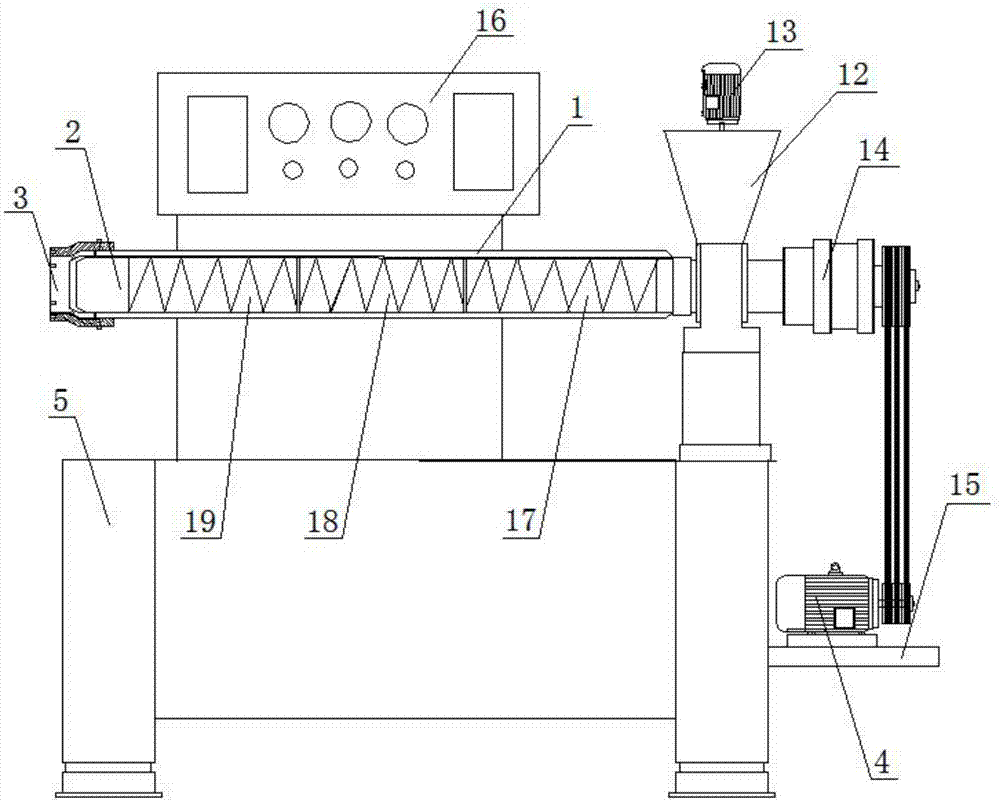

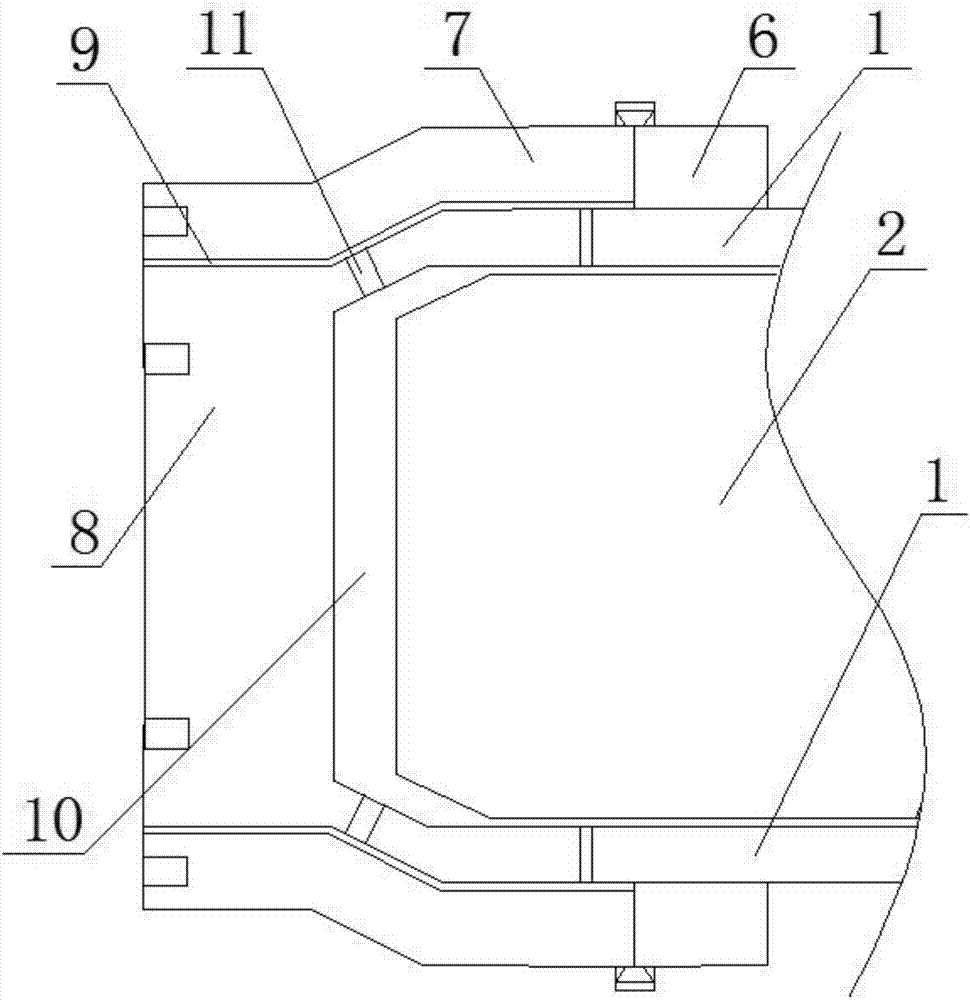

[0032] like figure 1 As shown, the screw extrusion equipment includes an extrusion barrel 1 with one end as the outlet end and the other end as the inlet end, an extrusion screw shaft 2 located inside the extrusion barrel 1 and passing through the extrusion barrel 1, The secondary kneading and forming device 3 fixed at the outlet end of the extrusion cylinder 1 is located above the inlet end of the extrusion cylinder 1 and is fixedly connected with the inlet end of the extrusion cylinder 1 for adding water to the raw materials High-speed rotation, stirring and mixing, and the uniformly mixed raw materials are sent to the stirring and feeding device at the inlet end of the extrusion cylinder 1, and the main motor 4 connected to the extrusion screw shaft 2 through a belt is installed on the extrusion cylinder 1 The frame 5 below and used to support the extruding barrel 1 and the extruding screw shaft 2; the extruding screw shaft 2 is fixedly connected with a speed reducer 14 at ...

Embodiment 2

[0038] A preparation method of non-fried instant noodles, comprising the following steps:

[0039] Step 1: Prepare materials: Weigh the raw materials by weight percentage, containing 95.7% of wheat flour, 4% of potato starch and 0.3% of palm oil.

[0040] Step 2: mixing materials: mixing the raw materials with water evenly to obtain a mixture; the water content of the mixture is 40%.

[0041] The screw extruding equipment that mixed material is placed in embodiment 1 carries out step 3 to step 5. The mixture enters the extrusion cylinder from the stirring and feeding device of the screw extrusion equipment, and is pushed forward under the action of the extrusion screw shaft, and passes through the first temperature control stage, the second temperature control stage, the third temperature control stage and the secondary kneading chamber in sequence. , and finally extrude from the gap, see step 3 to step 5 for details.

[0042] Step 3: Extrusion aging: the mixture is matured ...

Embodiment 3

[0047] A preparation method of non-fried instant noodles, comprising the following steps:

[0048] Step 1: preparing materials: weighing the raw materials; the raw materials contain 95.7% of wheat flour, 4% of potato starch and 0.3% of palm oil in weight percentage.

[0049] Step 2: mixing materials: mixing the raw materials with water evenly to obtain a mixture; the moisture content of the mixture is 44%.

[0050] The screw extruding equipment that mixed material is placed in embodiment 1 carries out step 3 to step 5. The mixture enters the extrusion cylinder from the stirring and feeding device of the screw extrusion equipment, and is pushed forward under the action of the extrusion screw shaft, and passes through the first temperature control stage, the second temperature control stage, the third temperature control stage and the secondary kneading chamber in sequence. , and finally extrude from the gap, see step 3 to step 5 for details.

[0051] Step 3: Extrusion aging: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com