Lead frame automatic chip loader

A lead frame and chip loading machine technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of lack of lead frame heating and oxidation protection, affecting the welding quality of chips and lead frames, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

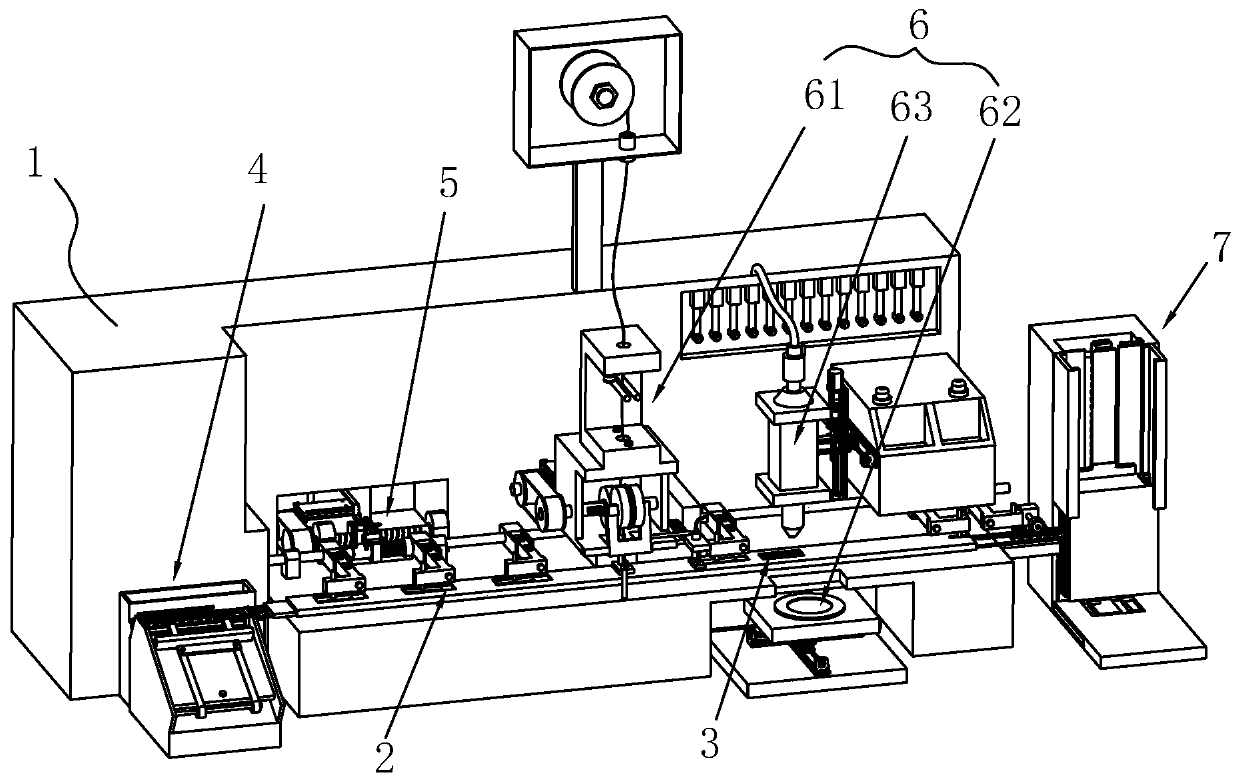

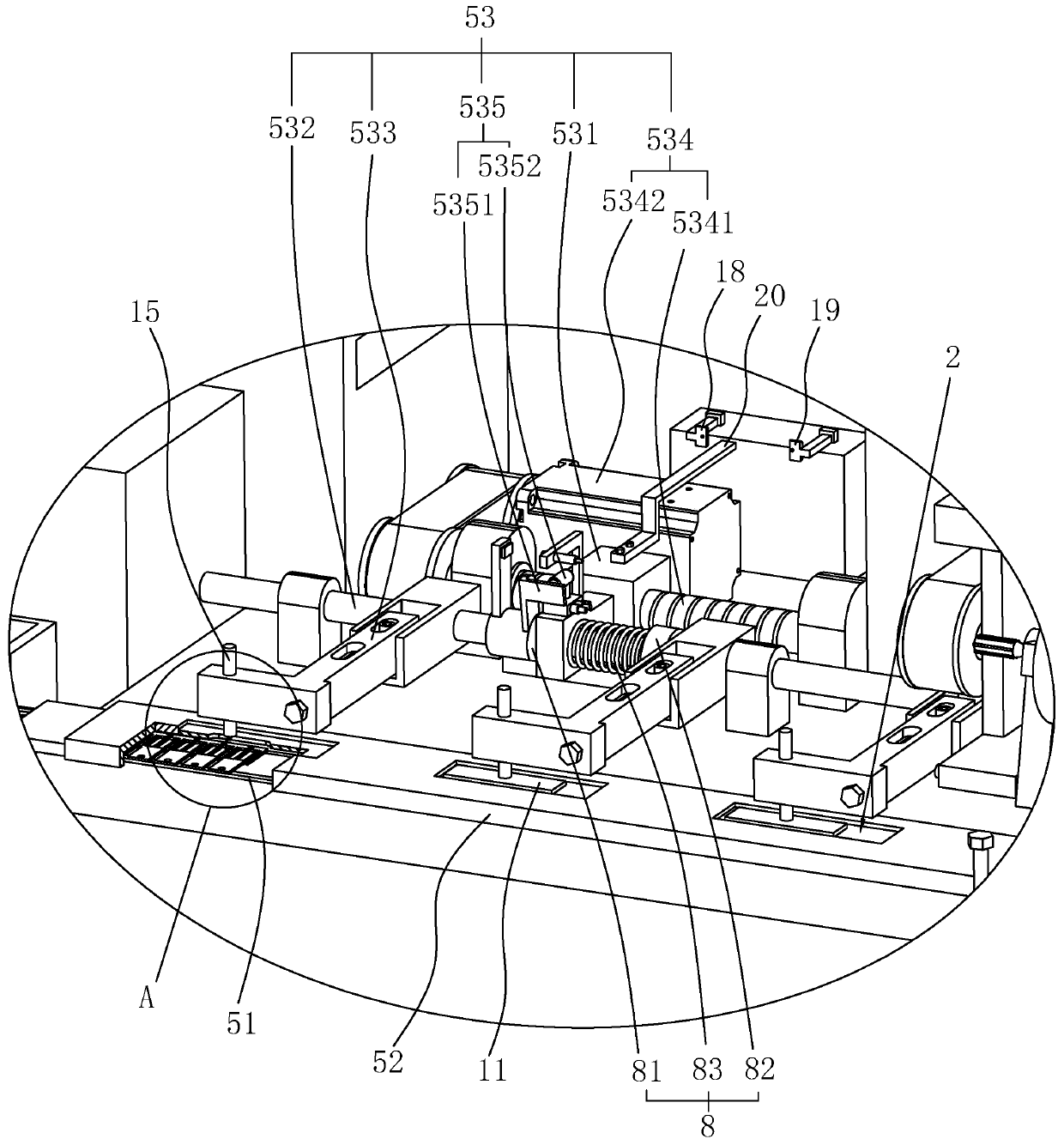

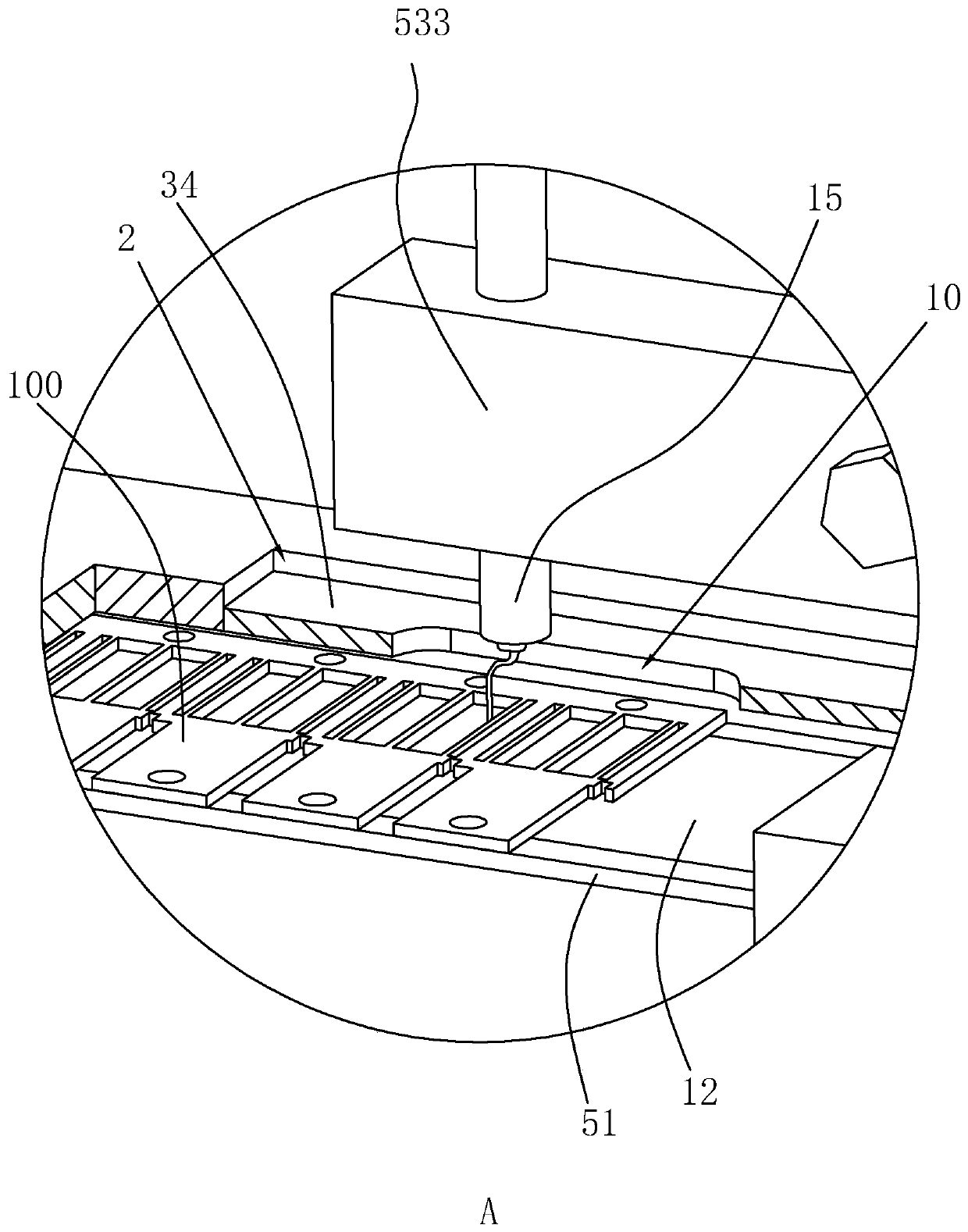

[0044] as attached figure 1 and image 3 The shown lead frame automatic chip loading machine includes a frame 1, a feeding device 4, a rail conveying device 5, a welding device 6 and an automatic chip loading device 7 arranged on the frame 1 in sequence. When working: first, the lead frame 100 is placed in the feeding device 4 and is loaded from the feeding device 4 to the rail conveying device 5; then, the rail conveying device 5 sends the lead frame 100 from one end of the feeding device 4 to the automatic loading device. One end of the chip device 7; wherein, the welding device 6 is located between the feeding device 4 and the automatic chip loading device 7, in order to complete the welding of the chip on the lead frame 100; finally, the lead frame 100 that has been welded is sent through the rail conveying device 5 into the automatic film loading devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com