A kind of equipment and method for producing oil by staged cocatalytic pyrolysis of agricultural and forestry waste and seaweed

A co-catalysis technology for agricultural and forestry wastes, applied in the preparation of liquid hydrocarbon mixtures, biofuels, and hydrocarbon oil treatment, can solve the problems of easy blockage of catalyst active sites, inability to contact solid catalysts, and difficulty in achieving catalytic effects. Achieve the effect of reducing the probability of deactivation, increasing the yield of pyrolysis, and saving external heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

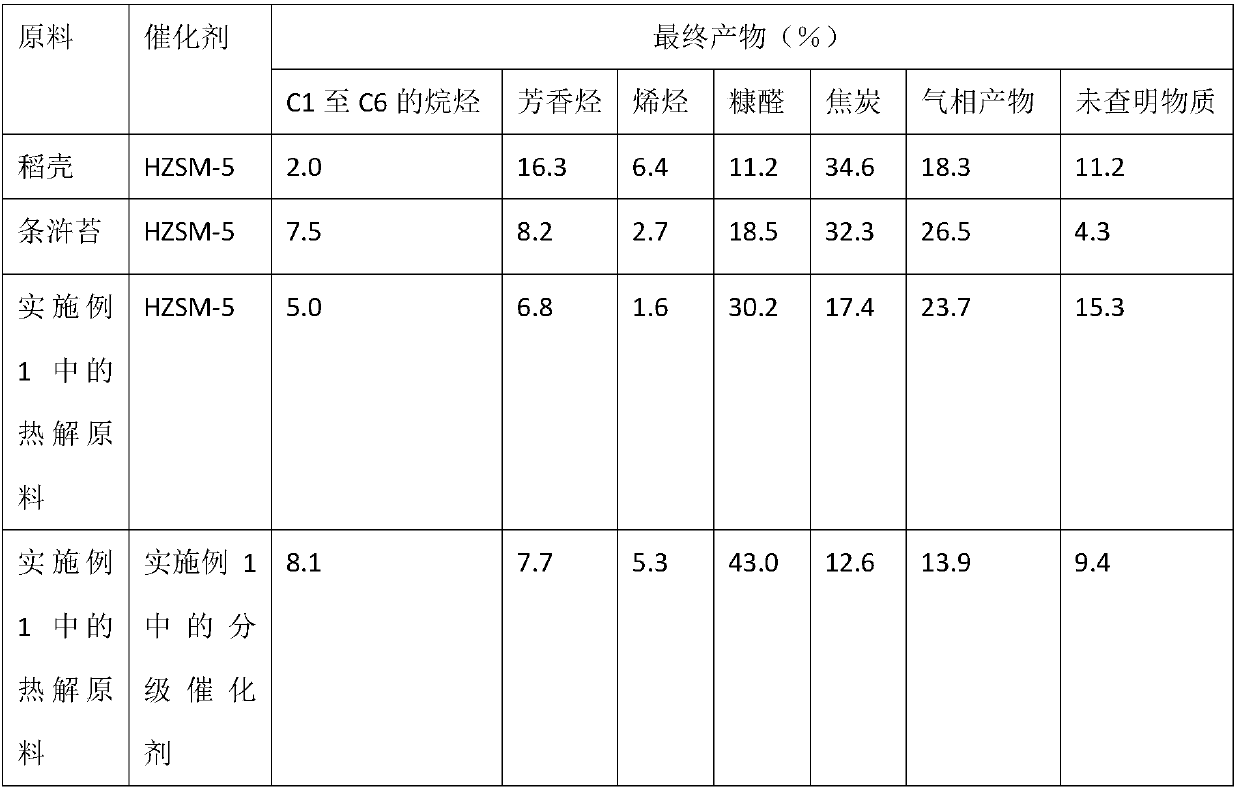

Examples

Embodiment 1

[0041] In this example, enteromorpha is selected to be dehydrated and dried to constant weight, and the algal powder particles are obtained after crushing and processing by a pulverizer. The mesh of the algal powder particles is between 200 and 400 mesh, and the rice husk is pulverized by a hammer mill. It is rice husk powder, which is then put into a constant temperature drying oven and dried at 105° C. to a constant weight. The rice husk particles have a mesh number between 20 and 140 mesh. Algae powder and rice husk powder are fully mixed according to the mass ratio of 1:3 as the pyrolysis raw material of this embodiment, and placed in the feed bin 9 .

[0042] The method for preparing the Ga-Ni / Si-HZSM-5 composite catalyst in this example is to first place the HZSM-5 powder in a muffle furnace for calcination at a temperature of 450°C for 4 hours, and then pulverize and sieve the HZSM-5 molecular sieve The particle size of the HZSM-5 molecular sieve is 80-160 mesh, and the...

Embodiment 2

[0045] In this example, enteromorpha is selected to be dehydrated and dried to constant weight, and the algal powder particles are obtained after crushing and processing by a pulverizer. The mesh of the algal powder particles is between 200 and 400 mesh, and the rice husk is pulverized by a hammer mill. It is rice husk powder, which is then put into a constant temperature drying oven and dried at 105° C. to a constant weight. The rice husk particles have a mesh number between 20 and 140 mesh. Algae powder and rice husk powder are fully mixed according to the mass ratio of 1:1 as the pyrolysis raw material of this embodiment, and placed in the feed bin 9 .

[0046] The method for preparing the Ga-Ni / Si-HZSM-5 composite catalyst in this example is to first place the HZSM-5 powder in a muffle furnace for calcination at a temperature of 450°C for 4 hours, and then pulverize and sieve the HZSM-5 molecular sieve The particle size of the HZSM-5 molecular sieve is 80-160 mesh, and the...

Embodiment 3

[0049]In this example, enteromorpha is selected to be dehydrated and dried to constant weight, and the algal powder particles are obtained after crushing and processing by a pulverizer. The mesh of the algal powder particles is between 200 and 400 mesh, and the rice husk is pulverized by a hammer mill. It is rice husk powder, which is then put into a constant temperature drying oven and dried at 105° C. to a constant weight. The rice husk particles have a mesh number between 20 and 140 mesh. Algae powder and rice husk powder are fully mixed according to the mass ratio of 1:2 as the pyrolysis raw material of this embodiment, and placed in the silo 9 .

[0050] The method for preparing the Ga-Ni / Si-HZSM-5 composite catalyst in this example is to first place the HZSM-5 powder in a muffle furnace for calcination at a temperature of 550°C for 4 hours, and then pulverize and sieve the HZSM-5 molecular sieve The particle size of the HZSM-5 molecular sieve is 80-160 mesh, and the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com