Biodegradable and disposable straw article and preparation method thereof

A biodegradable, disposable technology, applied in the field of catering utensils manufacturing, can solve the problems of excessive evaporation residue, easy formation of cholelithiasis, and new pollution, and achieve the effects of good hardness, good weaving, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

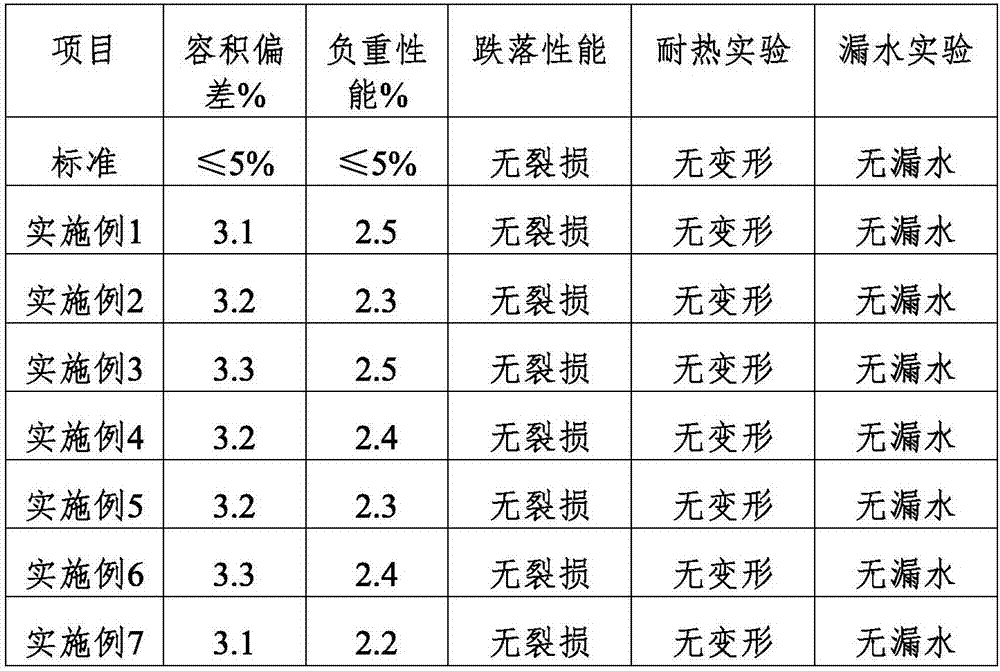

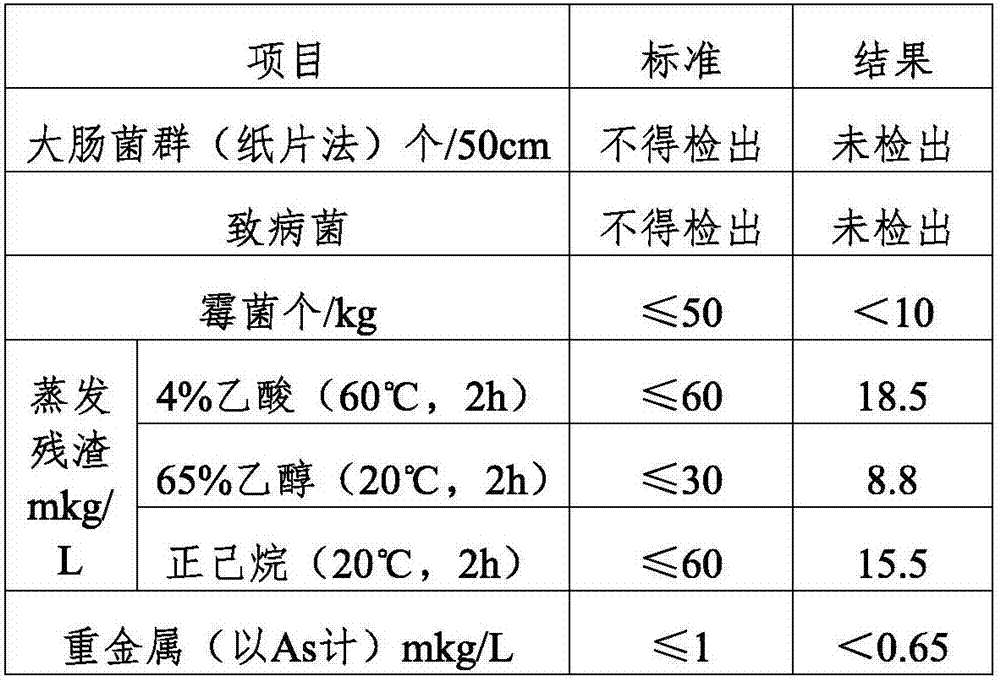

Examples

Embodiment 1

[0025] A biodegradable straw disposable product, consisting of the following raw materials in parts by mass: 20kg of straw powder, 15kg of starch, 10kg of fiber, 0.5kg of glycerin, 8kg of bioplastic, 0.5kg of release agent, 0.1kg of accelerator, and 30kg of water .

[0026] The preparation method of the biodegradable straw disposable product is to mix the raw material straw powder, starch, fiber, glycerin, bioplastic, release agent and accelerator in proportion, add water to make a paste, and put it into a bowl-shaped mold , heated to 200°C, and formed after 30s.

Embodiment 2

[0028] A biodegradable straw disposable product is composed of the following raw materials in parts by mass: 50kg of straw powder, 45kg of starch, 30kg of fiber, 5kg of glycerin, 30kg of bioplastic, 5kg of release agent, 0.5kg of accelerator, and 60kg of water.

[0029] The preparation method of the biodegradable straw disposable product is to mix the raw material straw powder, starch, fiber, glycerin, bioplastic, release agent and accelerator in proportion, add water to make a paste, and put it into a cup-shaped mold , heated to 240°C, and formed after 25s.

Embodiment 3

[0031] A biodegradable straw disposable product is composed of the following raw materials in parts by mass: straw powder 35kg, starch 28kg, fiber 20kg, glycerin 2.8kg, bioplastic 18kg, release agent 3kg, accelerator 0.3kg, water 45kg.

[0032] The preparation method of the biodegradable straw disposable product is to mix the raw material straw powder, starch, fiber, glycerin, bioplastic, release agent and accelerator in proportion, add water to make a paste, and put it into a beverage packaging cup In the mold, heat it to 180°C, and it can be formed after 35s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com