Substrate liquid processing apparatus and method

A technology of liquid treatment and treatment liquid, which is applied in the field of substrate liquid treatment equipment, can solve the problems of substrate chuck pin detachment, poor shape of substrate pattern, defective substrate, etc., so as to suppress the occurrence of granulation due to sharp temperature difference and suppress sharp temperature Differential granulation and the effect of preventing the shape defect of the substrate pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. The substrate liquid processing apparatus of the present invention can be divided into the first to sixth embodiments, and the constituent elements of each embodiment are basically the same, but there are differences in some configurations. In addition, the same reference numerals are used for components that have the same functions and actions in the plurality of embodiments of the invention.

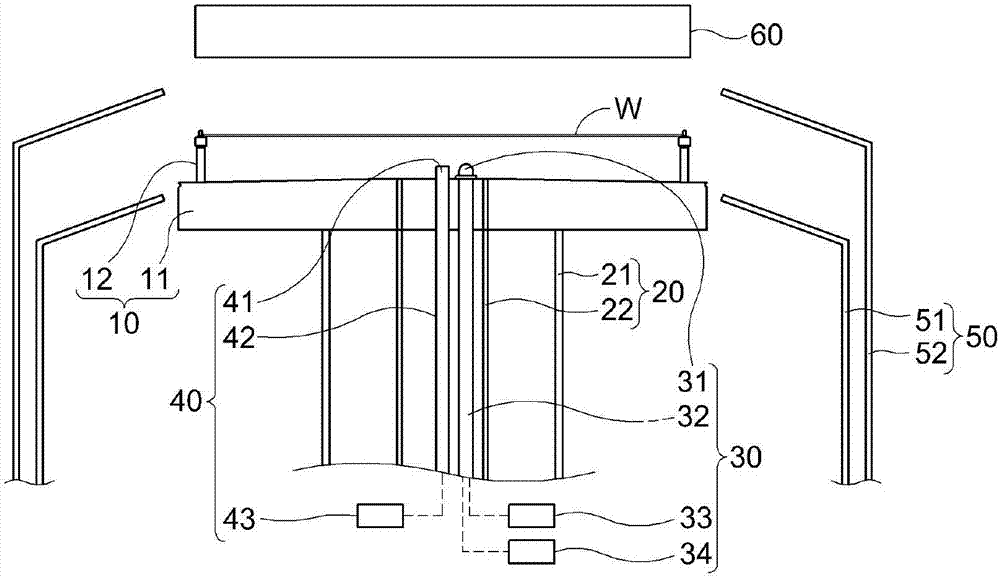

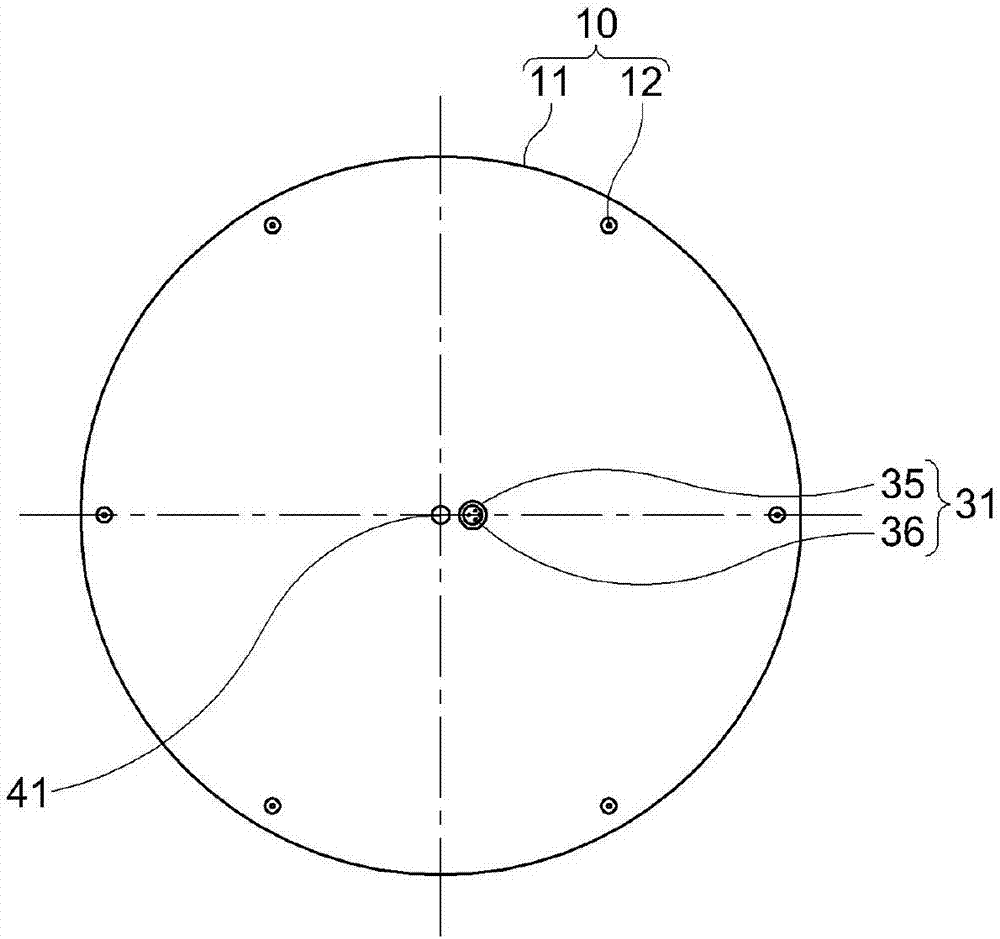

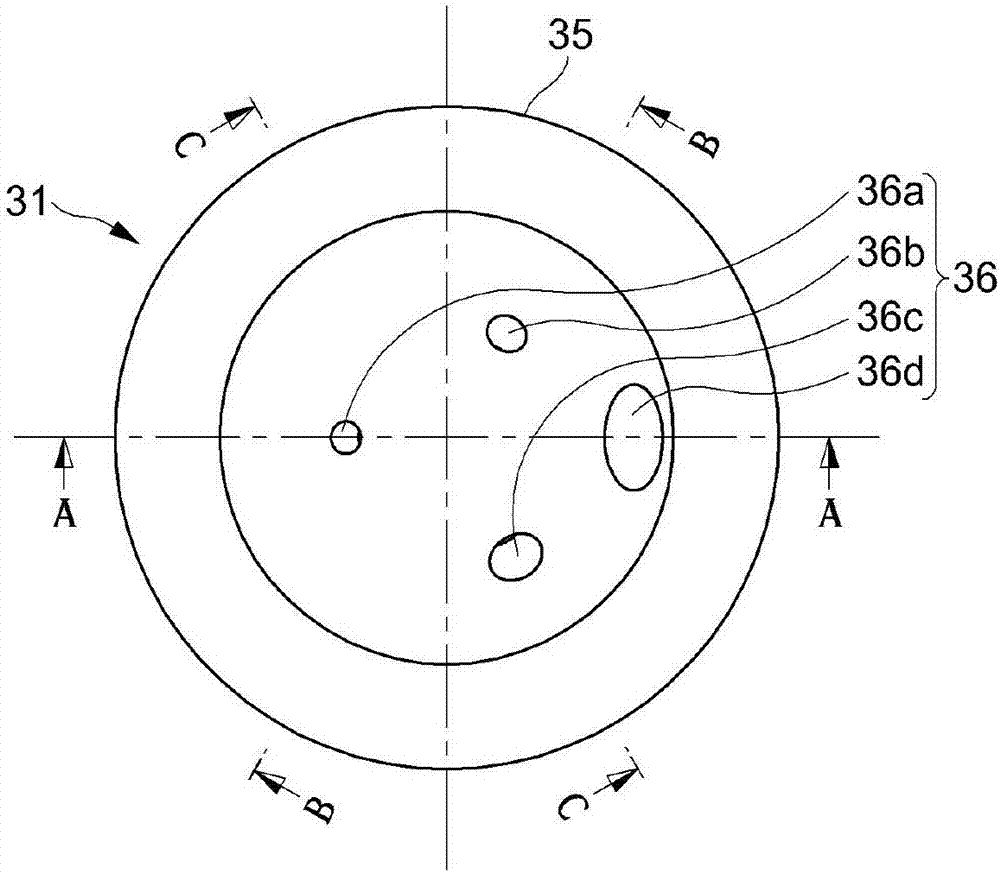

[0103] The present invention according to the first embodiment of the present invention is a substrate liquid processing device for supplying processing liquid to a substrate processing surface for liquid processing, such as figure 1 , figure 2 As shown in the figure, it is roughly composed of a substrate support unit 10 , a rotary drive unit 20 , a processing liquid supply unit 30 , a cleaning liquid supply unit 40 , a processing liquid recovery unit 50 and a heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com