Adhesive, adhesive sheet, and display element

A technology of adhesives and displays, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of light reflection loss and other problems, and achieve the effect of excellent step followability and high film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

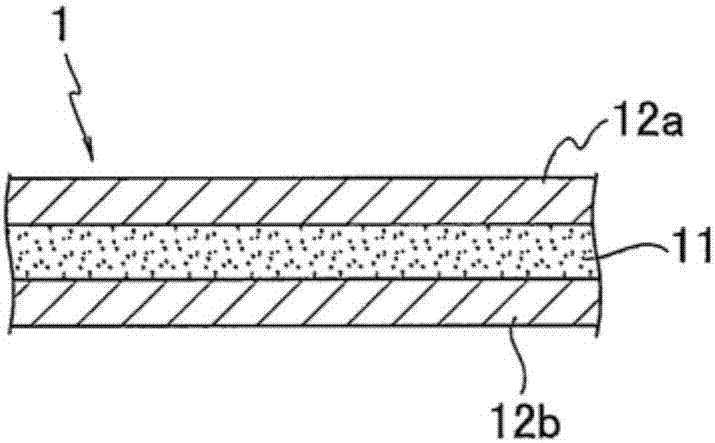

Image

Examples

Embodiment 1

[0152] 1. Preparation of (meth)acrylate polymer

[0153] Copolymerize 90 parts by mass of n-butyl acrylate and 10 parts by mass of acrylic acid to prepare a (meth)acrylate polymer (A), and measure the molecular weight of the (meth)acrylate polymer (A) by the method described later , The weight average molecular weight (Mw) is 400,000.

[0154] 2. Preparation of Adhesive Composition

[0155] 100 parts by mass of the (meth)acrylate polymer (A) obtained in the above step (1) (value in terms of solid content; the same applies below), and tris(propylene) as the active energy ray-curable component (B) Acyloxyethyl) isocyanurate (manufactured by TOAGOSEI CO., LTD., product name "M-315") 0.1 parts by mass, and 1,3-bis( N,N-diglycidylaminomethyl)cyclohexane (manufactured by MITSUBISH GAS CHEMICAL COMPANY, INC., product name "TETRAD-C", solid content concentration: 100% by mass) 0.05 parts by mass, and as silane coupling 0.2 parts by mass of 3-glycidyloxypropyltrimethoxysilane (manuf...

Embodiment 2~17、 comparative example 1~4

[0185] In addition to the proportion of each monomer constituting the (meth)acrylate polymer (A), the weight average molecular weight of the (meth)acrylate polymer (A), the type of active energy ray-curable component (B) and the addition The amount, the type and addition amount of the crosslinking agent (C), and the addition amount of the silane coupling agent were changed as shown in Table 1, and an adhesive sheet was produced in the same manner as in Example 1. In addition, Comparative Examples 1 and 4 were not subjected to ultraviolet irradiation treatment.

[0186] Here, the above-mentioned weight average molecular weight (Mw) is the weight average molecular weight in terms of polystyrene measured by gel permeation chromatography (GPC) under the following conditions (GPC measurement).

[0187]

[0188] ・GPC measurement device: manufactured by TOSOH CORPORATION, HLC-8020

[0189] ・GPC column (passed in the following order): manufactured by TOSOH CORPORATION

[0190] TSK...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com