Method for producing raw silk fleece products and fleece products

A manufacturing method and technology of raw silk, applied in the field of pile materials, can solve the problems of diffuse reflection, poor wear resistance, and poor wear resistance of fibrils, and achieve the effects of improving elasticity, improving stability, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

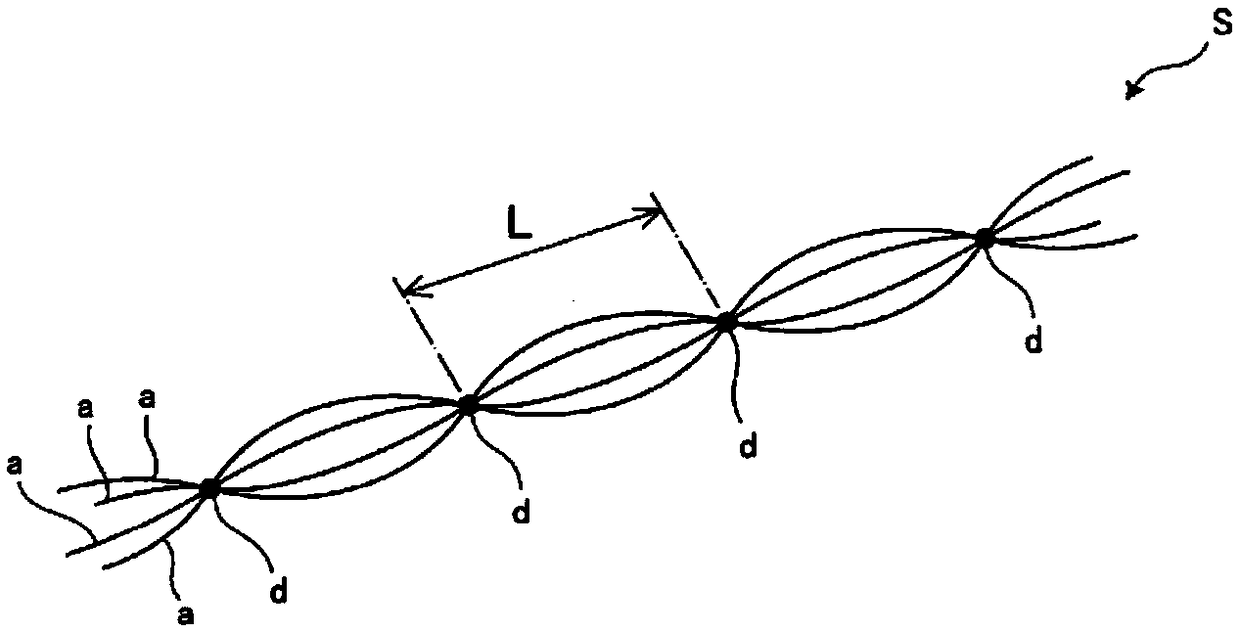

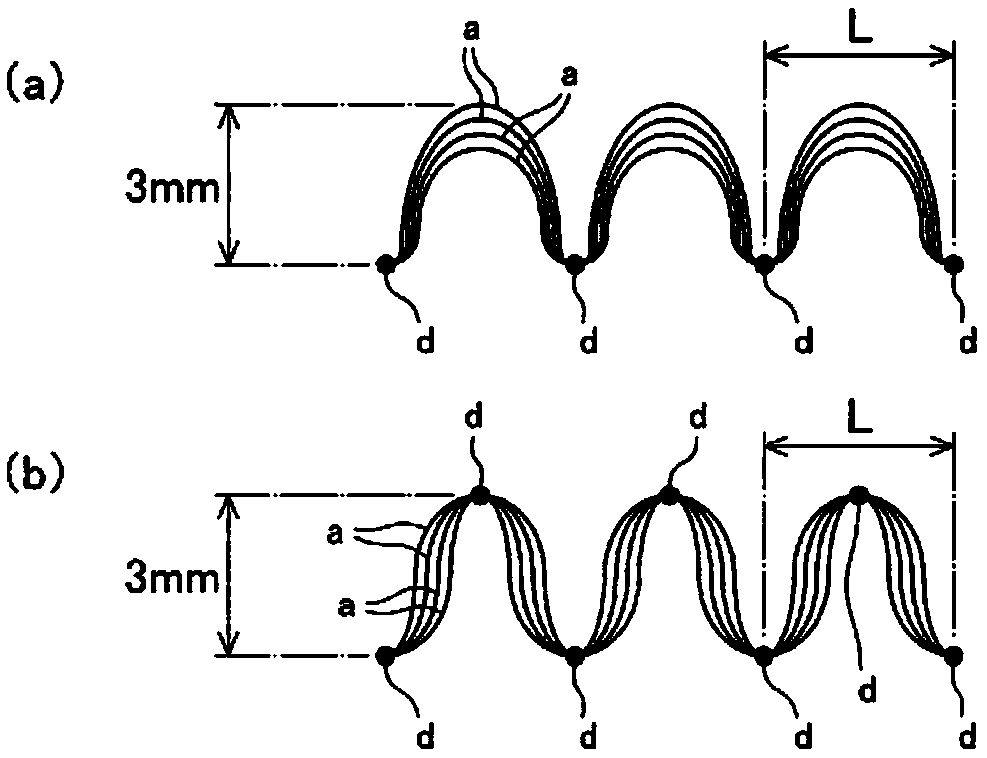

[0028] The invention provides a method for producing pile fabrics made of raw silk, which is characterized in that, when raw silk is used for pile weaving, the pile is woven by using sericin-fixed unidirectional twisted yarn formed on the basis of 4 to 8 raw silk The first fabric, and when performing one-way twisting of raw silk, use a loose and weak twist to obtain a tactile feel.

[0029] In addition, a fleece fabric product is provided, which uses 4 to 8 raw silks treated with sericin fixation, and utilizes unidirectional twisted yarn obtained by loose weak twisting to weave piles.

[0030] Embodiments of the present invention will be described in detail with reference to the drawings.

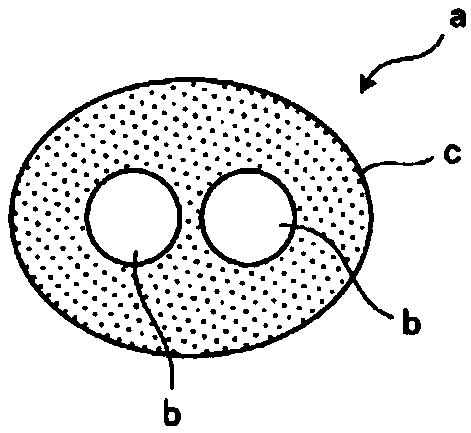

[0031] figure 1 This is an enlarged cross-sectional view showing silk pulled out from a cocoon, that is, raw silk (silk) a, in which two silk protein fibers (silk) b, b are wrapped by sericin c.

[0032] Usually, the weight ratio of sericin is about 25%, and the weight ratio of silk prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com