Magnetic copper-nickel-iron-cobalt alloy thin strip and preparation method therefor

A technology of magnetic alloys and iron-cobalt alloys, applied in the fields of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve ingot segregation, copper-nickel-iron magnetic alloy strips have not been seen, and are not suitable for thermal processing and other problems, to achieve the effect of high remanence and saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

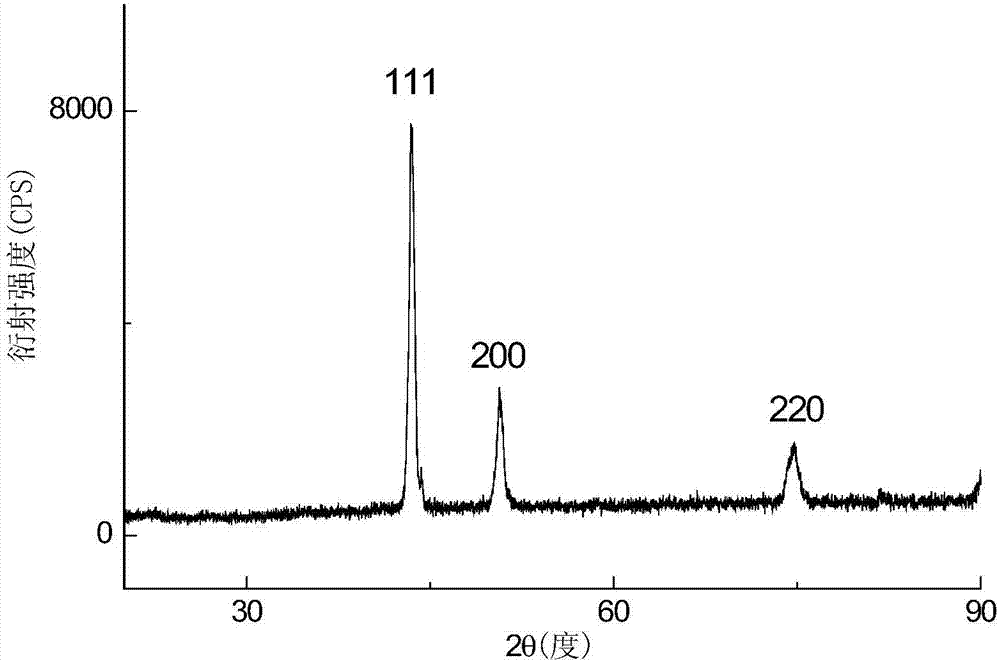

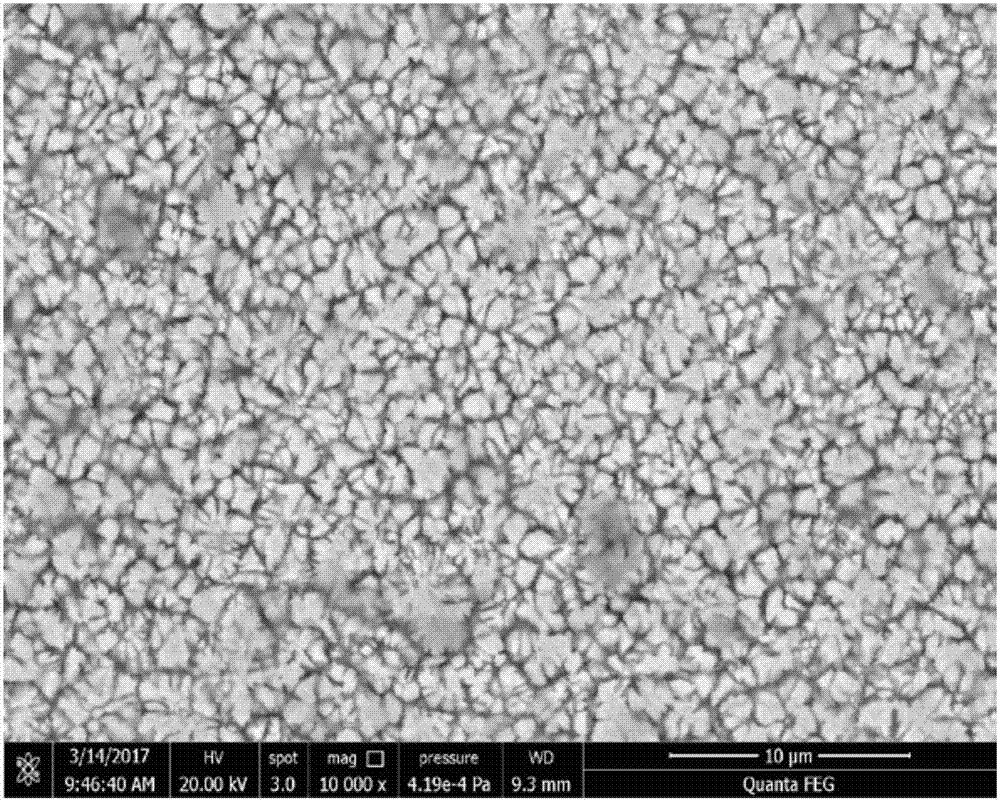

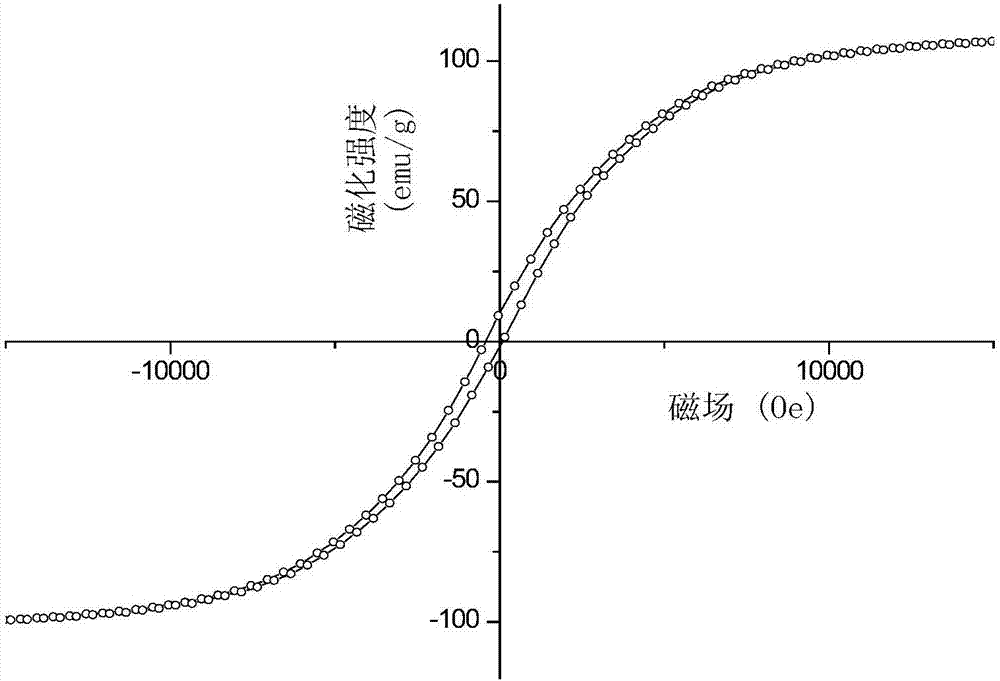

[0049] Prepare the element composition formula as Cu 35 Ni 25 Fe 20 co 20 Copper-nickel-iron-cobalt magnetic alloy thin strip product, the thickness of the thin strip is 63μm, and the magnetic properties are measured on a vibrating sample magnetometer with an external magnetic field of 20kOe. The coercive force is 368.3Oe, the remanence is 6.6emu / g, and the saturation The magnetization is 102.6emu / g.

[0050] The first step is to prepare raw materials:

[0051] Calculate the element composition formula Cu according to the atomic percentage of the element 35 Ni 25 Fe 20 co 20 The mass percentage of the constituent elements in the mass percentage, take the required amount of component raw materials according to the mass percentage: pure Cu, pure Ni, pure Fe, pure Co, thus complete the preparation of raw materials;

[0052] The second step is to melt the raw materials to prepare copper-nickel-iron-cobalt master alloy ingots:

[0053] Put all the raw materials prepared in...

Embodiment 2

[0062] Prepare the element composition formula as Cu 50 Ni 20 Fe 15 co 15 Copper-nickel-iron-cobalt magnetic alloy thin strip product, the thickness of the thin strip is 65μm, and the magnetic properties are measured on a vibrating sample magnetometer with an external magnetic field of 20kOe. The coercive force is 325.4Oe, the remanence is 7.5emu / g, and the saturation The magnetization is 90.9emu / g.

[0063] The first step is to prepare raw materials:

[0064] Calculate the element composition formula Cu according to the atomic percentage of the element 50 Ni 20 Fe 15 co 15 The mass percentage of the constituent elements in the mass percentage, take the required amount of component raw materials according to the mass percentage: pure Cu, pure Ni, pure Fe, pure Co, thus complete the preparation of raw materials;

[0065] The second step is to melt the raw materials to prepare copper-nickel-iron-cobalt master alloy ingots:

[0066] Put all the raw materials prepared in ...

Embodiment 3

[0075]Prepare the element composition formula as Cu 55 Ni 17.5 Fe 13.75 co 13.75 Copper-nickel-iron-cobalt magnetic alloy thin strip product, the thickness of the thin strip magnet product is 58μm, and the magnetic properties are measured on a vibrating sample magnetometer with an external magnetic field of 20kOe. The coercive force is 353.4Oe and the residual magnetism is 6.6emu / g , The saturation magnetization is 85.0emu / g.

[0076] The first step is to prepare raw materials:

[0077] Calculate the element composition formula Cu according to the atomic percentage of the element 55 Ni 17.5 Fe 13.75 co 13.75 The mass percentage of the constituent elements in the mass percentage, take the required amount of component raw materials according to the mass percentage: pure Cu, pure Ni, pure Fe, pure Co, thus complete the preparation of raw materials;

[0078] The second step is to melt the raw materials to prepare copper-nickel-iron-cobalt master alloy ingots:

[0079] Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com