Substrate for sensor, physical quantity detection sensor

A technology for detecting sensors and sensors, used in instruments, measuring devices, measuring acceleration, etc., can solve problems such as difficulties, inability to meet the detection range of physical quantities of acceleration, damage to sensor substrates or physical quantity detection elements, etc., to achieve the effect of thermal stress suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

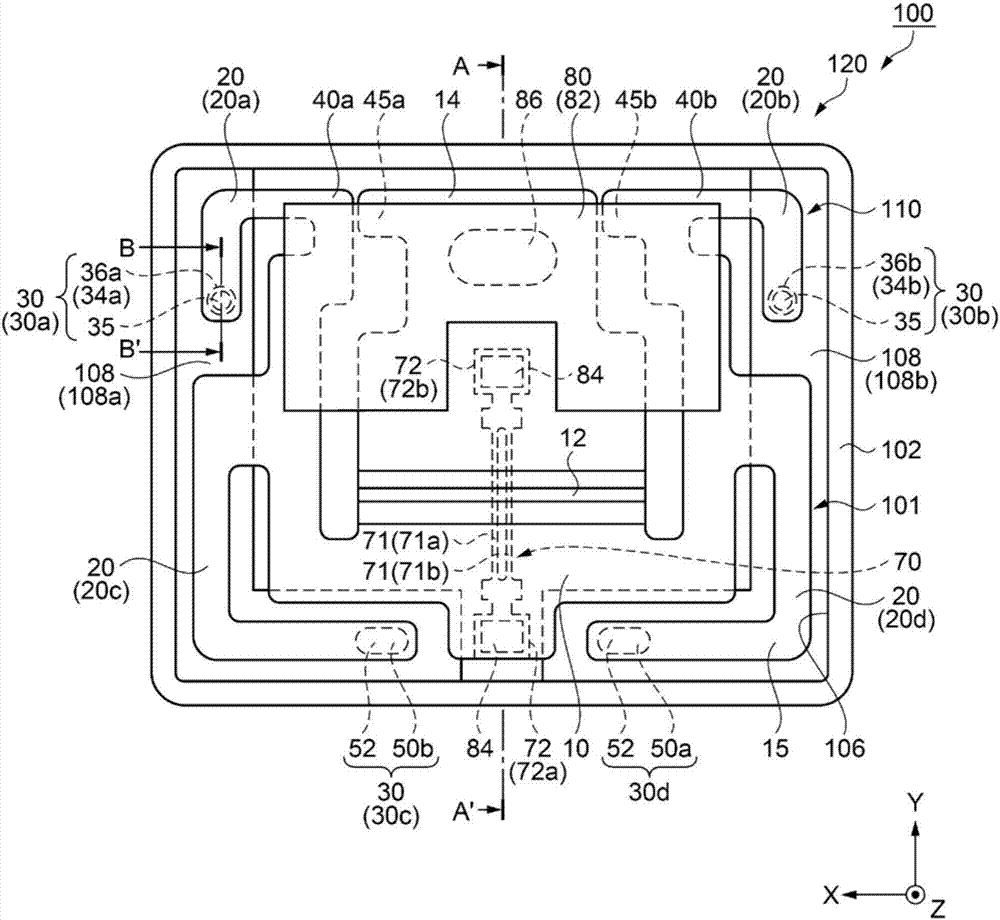

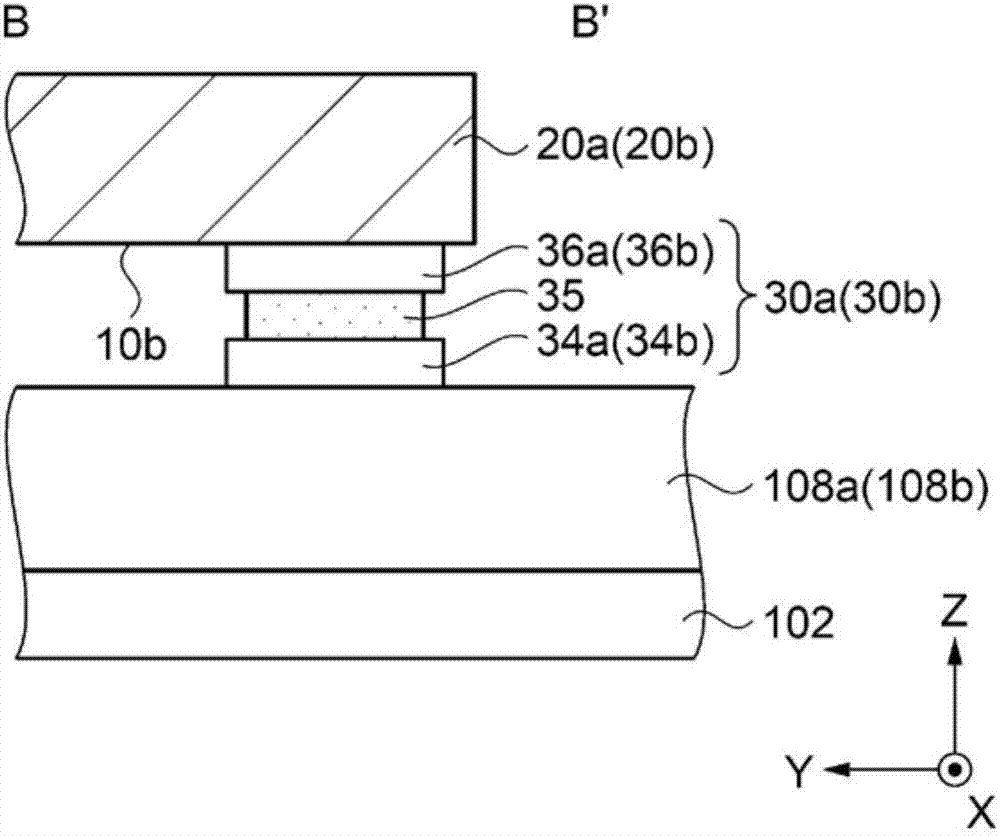

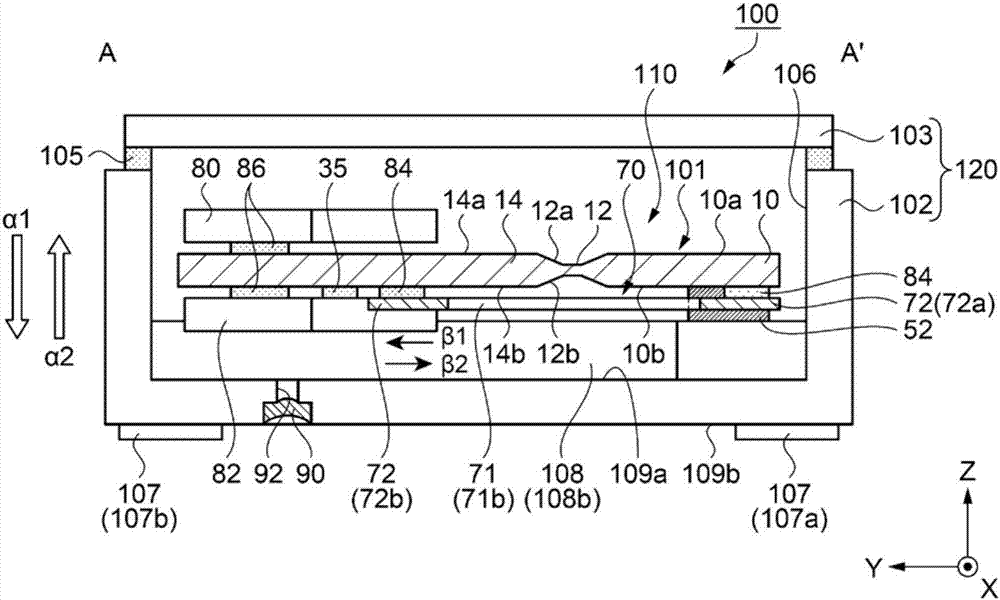

Image

Examples

Embodiment

[0198] Next, an example to which the physical quantity detection sensor 100 according to one embodiment of the present invention is applied will be described with reference to the drawings.

[0199] Figure 11A It is a perspective view showing a video camera equipped with a physical quantity detection sensor 100, Figure 11B is a perspective view showing a mobile phone equipped with the physical quantity detection sensor 100, Figure 12 It is a perspective view showing an automobile as a moving body on which the physical quantity detection sensor 100 is mounted.

[0200] Electronic equipment

[0201] Such as Figure 11A , Figure 11B As shown, a video camera 500 and a mobile phone 600 as electronic devices are equipped with the physical quantity detection sensor 100 according to the present embodiment.

[0202] first, Figure 11A The shown video camera 500 includes an image receiving unit 501 , an operation unit 502 , a voice input unit 503 , and a display unit 504 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com