Energy-saving and environment-protecting wall-mounted furnace and application method thereof

An energy-saving and environment-friendly wall-hung boiler technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high sealing requirements, low utilization rate of flue gas heat, environmental and air pollution, etc. To achieve the effect of simple equipment structure and production process, which is conducive to environmental protection and reduces air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

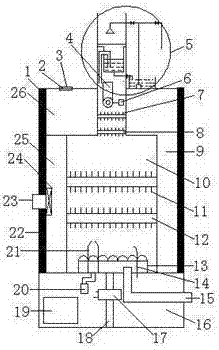

[0041]An energy-saving and environment-friendly wall-hung furnace is provided, which includes a furnace body 1, an insulation layer 22 is provided on the outer wall of the furnace body 1, and insulation materials such as insulation boards can be selected to prevent heat from spreading. The center of the furnace body 1 is provided with a combustion chamber 10 , one side of the combustion chamber 10 is provided with an air heat absorption bin 9, and the other side of the combustion chamber 10 is provided with an air buffer bin 26 and a hot air collection bin 25 in turn, and the air buffer bin 26 is provided with an inlet The air inlet 2 is provided with an air filter 3; the hot air collection chamber 25 is provided with a hot air outlet 23, and the hot air outlet 23 is provided with a blower 24.

[0042] At least one set of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com