Graphical quantum-dot thin film preparation method based on electrostatic induction

An electrostatic induction and thin film preparation technology, which is applied in semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, circuits, etc., can solve the problems of insufficient precision, affecting the display quality of displays, and low manufacturing costs. The effect of high control precision, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

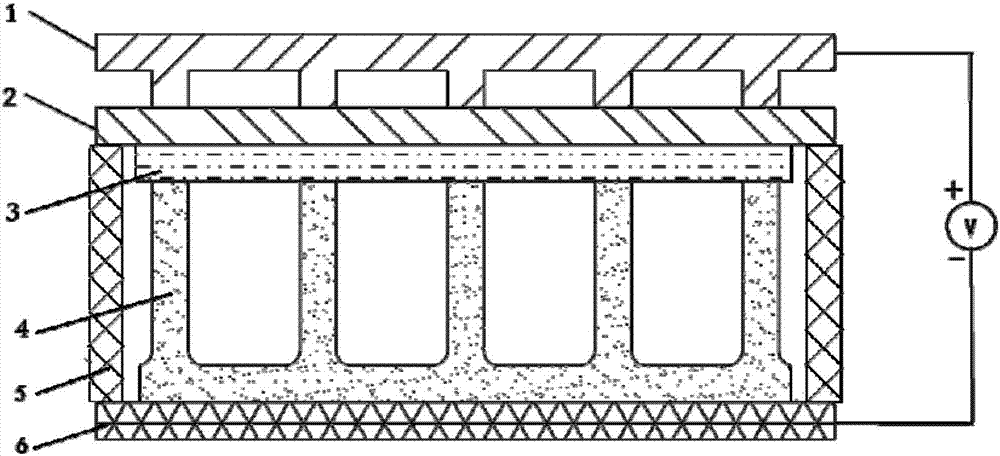

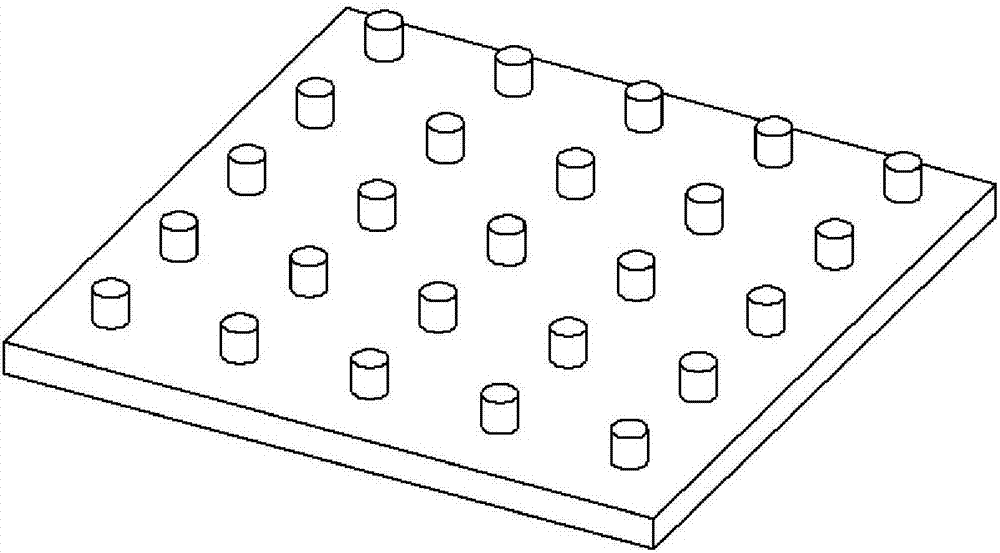

[0046] This embodiment provides a method for preparing a patterned quantum dot film based on electrostatic induction, comprising the following steps:

[0047] (1) Preparation and processing of the array template: select a rectangular red copper plate with a size of 50 mm×100 mm and a thickness of 2 mm, and use photolithography and etching processes to process the required micro-column array pattern structure on one surface of the copper plate, as The array template of the electrostatic induction process; the processed micro-pillar array is a cylindrical array, the diameter of the micro-cylindrical bottom of the cylindrical array is 2 μm, the height range of the micro-cylindrical is 4 μm, and the distance between the central axes of the adjacent micro-pillars of the array mold is 5 μm; Electrodes and wires are pasted on the unstructured surface, and connected to the positive pole of the DC power supply.

[0048] (2) Preparation of quantum dot reaction solution: quantum dot reac...

Embodiment 2

[0055] This embodiment provides a method for preparing a patterned quantum dot film based on electrostatic induction, comprising the following steps:

[0056] (1) Preparation and processing of the array template: select a rectangular copper plate with a size of 50mm×100mm and a thickness of 2mm, and use photolithography and etching processes to process the required micro-column array pattern structure on one surface of the copper plate, as The array template of the electrostatic induction process; the processed micro-column array is a square column array, the side length of the bottom surface of the square column array is 0.1 μm, the height of the micro-square column is 1 μm, and the distance between the central axes of the adjacent micro-columns of the array mold is 0.5 μm; paste electrodes and wires on the unstructured surface of the array mold, and connect the positive pole of the DC power supply.

[0057] (2) Preparation of quantum dot reaction solution: quantum dot reacti...

Embodiment 3

[0064] This embodiment provides a method for preparing a patterned quantum dot film based on electrostatic induction, comprising the following steps:

[0065] (1) Preparation and processing of the array template: select a rectangular copper plate with a size of 50mm×100mm and a thickness of 2mm, and use photolithography and etching processes to process the required micro-column array pattern structure on one surface of the copper plate, as The array template of the electrostatic induction process; the processed micro-pillar array is a cylindrical array, the diameter of the micro-cylindrical bottom of the cylindrical array is 10 μm, the height of the micro-square column is 100 μm, and the distance between the central axes of the adjacent micro-pillars of the array mold is 15 μm; Electrodes and wires are pasted on the unstructured surface, and connected to the positive pole of the DC power supply.

[0066] (2) Preparation of quantum dot reaction solution: quantum dot reaction so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com