Method for preparing nano-melt-blown non-woven fabrics by electrospinning

A technology of melt-blown non-woven fabric and electrospinning method, which is applied in the direction of non-woven fabrics, textiles and papermaking, and can solve the problems that ultra-high modulus polyethylene and polypropylene nano-melt-blown non-woven fabrics cannot be prepared, and achieve It is convenient for industrial application, the operation process is simple, and the effect of increasing electrostatic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

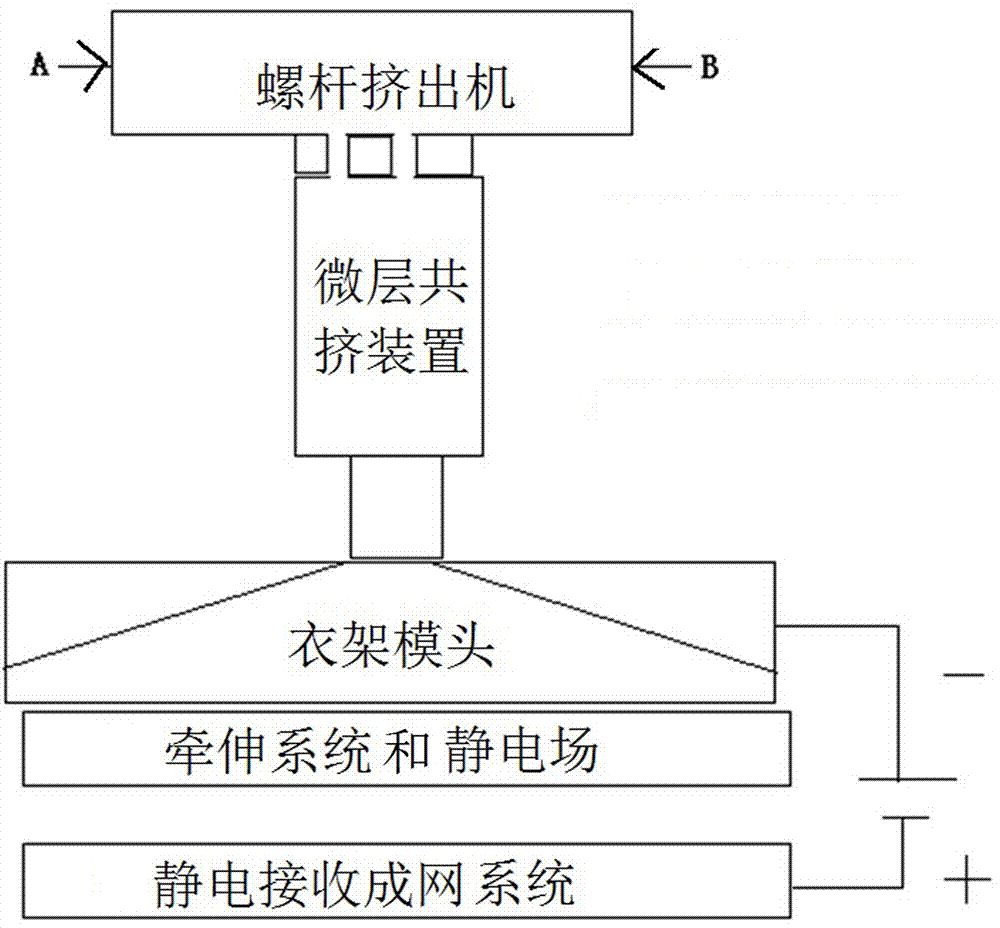

[0021] like figure 1 As shown, the method for preparing nano-melt-blown non-woven fabrics by electrospinning in this example includes the following steps: (1) Raw material component A: a mixture of white oil and ultra-high modulus polyethylene and raw material component B: Polypropylene for melt blowing with a melt index of 405g / 10min is fed from the two screws of the three-screw extruder respectively, wherein the weight ratio of white oil to ultra-high modulus polyethylene is 95:5; (2) the In the above step (1), component A and component B are introduced into the micro-layer co-extrusion device under the action of the three-screw extruder, and the laminated material with a layer number of 35 is extruded through the micro-layer co-extrusion device; (3) The laminated material prepared in the above step (2) enters a clothes hanger die head provided with a slit outlet, and the laminated material is extruded into a melt film with 35 layers and a thickness of 50 μm; (4) the melt U...

Embodiment 2

[0023] like figure 1 As shown, the method for preparing nano-melt-blown non-woven fabrics by electrospinning in this embodiment includes the following steps: (1) mixing raw material component A: a mixture of white oil and ultra-high modulus polyethylene and Raw material component B: Polypropylene for melt blowing with a melt index of 410g / 10min is fed from the two screws of the twin-screw extruder respectively, wherein the weight ratio of white oil to ultra-high modulus polyethylene is 85:15; (2) Import component A and component B in the step (1) into the micro-layer co-extrusion device under the action of the twin-screw extruder, and extrude a laminated material with 200 layers through the micro-layer co-extrusion device (3) The laminated material obtained in the step (2) enters a clothes hanger die with two slit outlets at equidistant intervals, and extrudes the laminated material into a melt with 200 layers and a thickness of 100 μm (4) Under the action of the hot air flow...

Embodiment 3

[0025] like figure 1 As shown, the method for preparing nano-melt-blown non-woven fabrics by electrospinning in this embodiment includes the following steps: (1) mixing raw material component A: a mixture of white oil and ultra-high modulus polyethylene and Raw material component B: Polypropylene for melt blowing with a melt index of 430g / 10min is fed from the two screws of the twin-screw extruder respectively, wherein the weight ratio of white oil to ultra-high modulus polyethylene is 80:10; (2) Import component A and component B in the step (1) into the micro-layer co-extrusion device under the action of the twin-screw extruder, and extrude a laminated material with 256 layers through the micro-layer co-extrusion device (3) The laminated material obtained in the step (2) enters a clothes hanger die with two slit outlets at equidistant intervals, and the laminated material is extruded into a melt with 256 layers and a thickness of 500 μm (4) Under the action of the hot air f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com