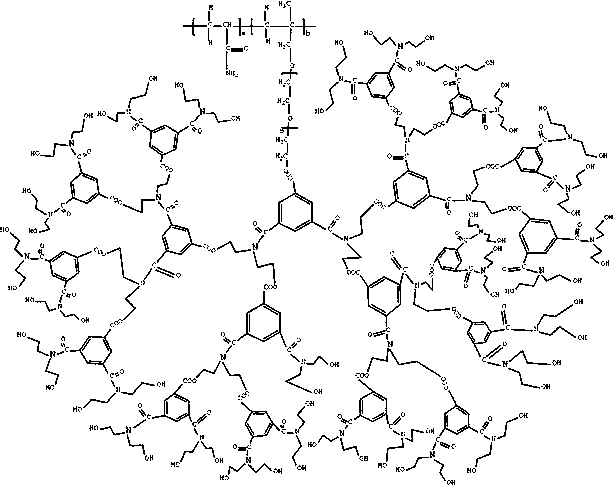

Preparation and application of hydroxyl-terminated hyperbranched polyamide retarder

A technology of hydroxyl-terminated hyperbranched and hyperbranched polymers is applied in the field of retarders, which can solve the problems of poor fluidity and short retardation time of concrete, and achieve the improvement of retardation performance, water reduction efficiency and compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

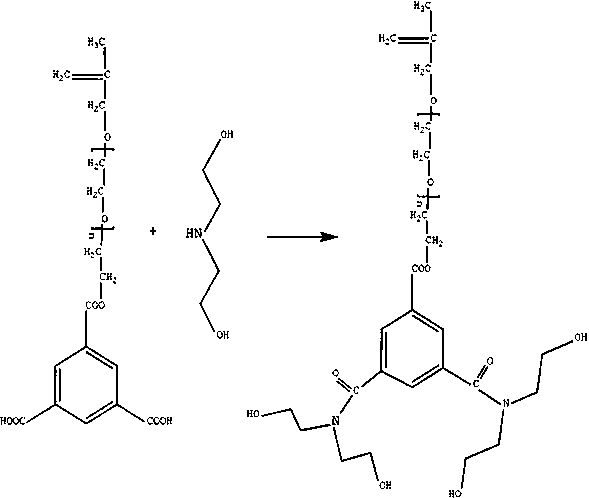

[0035] (1) Utilize the amidation reaction, under the action of the catalyst p-toluenesulfonic acid, take DMAc as the solution and toluene as the water-carrying agent, weigh 25g of methallyl polyoxyethylene ether, 10.5g of trimesic acid, 5.25 Add 1 g of diethanolamine into a three-necked flask with mixing and stirring, carry out condensation reaction at 50°C, react for 12-48 hours, control the algebra of hyperbranching by repeatedly adding monomers, and synthesize the first and second generation hyperbranched polymers. Take a certain amount of hyperbranched polymer and acrylamide, mix them into a three-necked flask, add a certain amount of initiator to carry out addition polymerization, stir and heat up to 65°C, stir for 8 hours, and finally adjust the pH with 40% sodium hydroxide solution =7~7.5, and then distilled under reduced pressure to obtain the finished product of hyperbranched coagulant.

[0036] (2) The coagulation time is measured by a penetration resistance meter wi...

Embodiment approach 2

[0039] (1) Utilize amidation reaction, under the action of catalyst p-toluenesulfonic acid, take DMAc as solution and toluene as water-carrying agent, weigh 25g methallyl polyoxyethylene ether, 21g trimesic acid, 10.5g Diethanolamine is mixed and stirred into a three-necked flask, and the condensation reaction is carried out at 50°C for 12 to 48 hours. By repeatedly adding monomers, the algebra of hyperbranching is controlled, and the first and second generation hyperbranched polymers are synthesized. Take a certain amount of hyperbranched polymer, sodium methacryl sulfonate, and acrylamide, mix them into a three-necked flask, add a certain amount of initiator for addition polymerization, stir and heat up to 65°C, stir for 8 hours, and finally use 40% The sodium hydroxide solution is used to adjust the pH=7 to 7.5, and then distilled under reduced pressure to obtain the finished product of the hyperbranched coagulant.

[0040] (2) The coagulation time is measured by a penetrat...

Embodiment approach 3

[0043](1) Utilize amidation reaction, under the action of catalyst p-toluenesulfonic acid, take DMAc as solution and toluene as water-carrying agent, weigh 20g methallyl polyoxyethylene ether, 21g trimesic acid, 10.5g Diethanolamine is mixed and stirred into a three-necked flask, and the condensation reaction is carried out at 50°C for 12 to 48 hours. By repeatedly adding monomers, the algebra of hyperbranching is controlled, and the first and second generation hyperbranched polymers are synthesized. Take a certain amount of hyperbranched polymer, sodium methacryl sulfonate, and acrylamide, mix them into a three-necked flask, add a certain amount of initiator for addition polymerization, stir and heat up to 65°C, stir for 8 hours, and finally use 40% The sodium hydroxide solution is used to adjust the pH=7 to 7.5, and then distilled under reduced pressure to obtain the finished product of the hyperbranched coagulant.

[0044] (2) The coagulation time is measured by a penetrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com