Acrylic surface treatment process

A surface treatment and acrylic technology, applied in the direction of surface pretreatment, bonding method, etc., can solve the problems of product quality not being well guaranteed and fastness, etc., to achieve reliable product quality, enhanced adhesion, Significant economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An acrylic surface treatment process:

[0024] 1. Select a suitable acrylic 1 (acrylic plate in this embodiment);

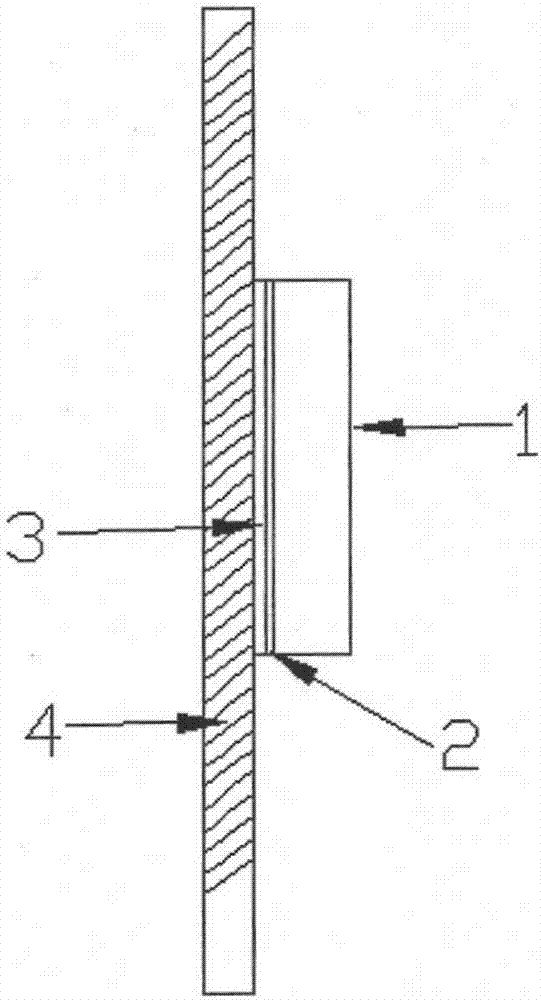

[0025] 2. Spray a plastic primer on the back of the acrylic 1, and after the plastic primer is cured for 10 minutes, a plastic primer layer 2 is formed on the surface of the acrylic 1;

[0026] 3. Apply silicone structural adhesive 3 on the surface of the plastic primer layer 2, and bond it to the base layer 4 (such as figure 2 shown).

Embodiment 2

[0028] An acrylic surface treatment process:

[0029] 1. First, carve acrylic 1 into three-dimensional acrylic characters;

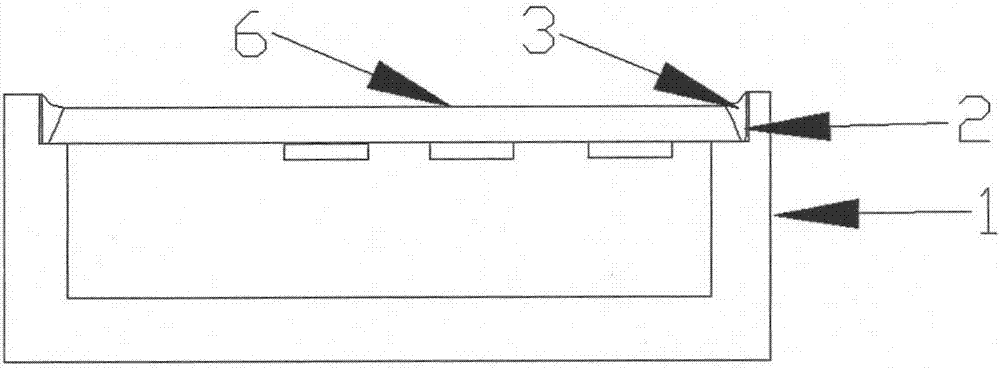

[0030] 2. Brush the plastic primer on the part of the back of the carved acrylic 1 that is to be bonded to the light bar 6. After the plastic primer is cured for 8 minutes, a plastic primer layer 2 is formed on the surface of the acrylic 1;

[0031] 3. Put the lighting board 6 in place, and apply silicone structural glue 3 between the lighting board 6 and the plastic primer layer 2 (such as figure 2 shown).

Embodiment 3

[0033] An acrylic surface treatment process:

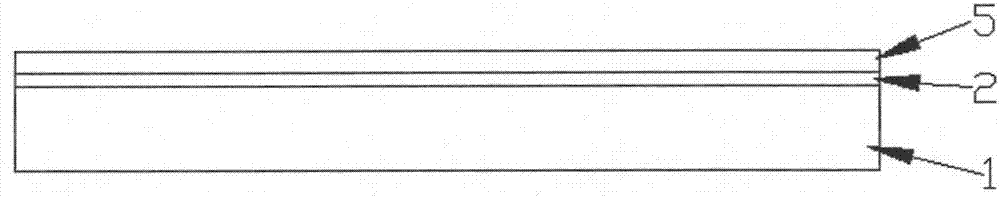

[0034] 1. Select the appropriate acrylic 1;

[0035] 2. Spray a plastic primer on the surface of the acrylic 1, and after the plastic primer is cured for 12 minutes, a plastic primer layer 2 is formed on the surface of the acrylic 1;

[0036] 3. Print UV picture 5 on acrylic 1, such as image 3 shown.

[0037] After the product prepared in Examples 1-3 was left to stand at normal temperature for one month, the surface was scratched with a blade, and there was no paint drop substantially. Therefore, it can be seen from the test that:

[0038] 1. The surface roughness of acrylic is different, and the smooth and smooth effect can be obtained through the pretreatment of plastic primer; the silicone structural adhesive is used to enhance the adhesion;

[0039] 2. The low polarity of acrylic surface usually has poor adhesion with direct silicone structural adhesive, and better adhesion performance can be obtained through plastic pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com