Micro-foamed water-based damping coating and preparation method thereof

A damping coating and micro-foaming technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult stabilization of foaming gas, long curing time of coating, difficulty in cell size and density Control and other issues to achieve the effect of improving the curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

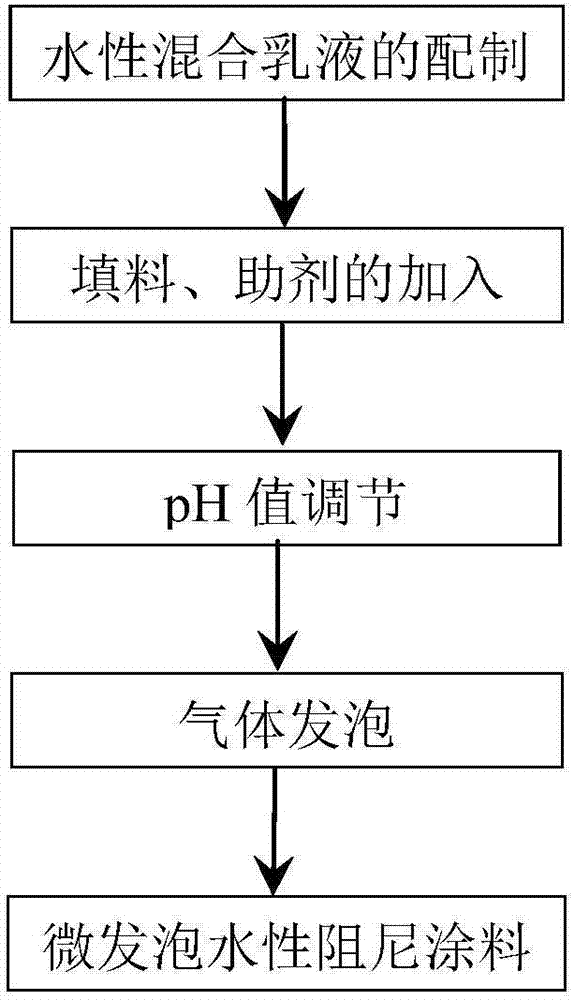

Method used

Image

Examples

Embodiment 1

[0028] A micro-foaming water-based damping coating, which uses water-based emulsion as the main agent, damping fillers as the main filler, organic fillers as auxiliary fillers, and an appropriate amount of crosslinking agent, catalyst, gas foaming agent and water;

[0029] Contains the following raw materials in parts by weight:

[0030] 10 parts of water-based emulsion, 80 parts of damping filler, 0.5 part of organic filler, 50 parts of crosslinking agent, 0.01 part of catalyst, 30 parts of water;

[0031] Gas blowing agent is CO 2 Gas, the temperature of the gas blowing agent is 220°C, and the pressure of the gas blowing agent is 10Mpa.

[0032] Preferably, the aqueous emulsion is a mixed solution of an aqueous acrylic resin emulsion and an alkyd resin emulsion, wherein both the aqueous acrylic resin and the alkyd resin have a glass transition temperature of 20°C to 30°C.

[0033] Preferably, the damping filler is flake mica and graphite.

[0034] Preferably, the organic ...

Embodiment 2

[0044] A micro-foaming water-based damping coating, which uses water-based emulsion as the main agent, damping fillers as the main filler, organic fillers as auxiliary fillers, and an appropriate amount of crosslinking agent, catalyst, gas foaming agent and water;

[0045] Contains the following raw materials in parts by weight:

[0046] 60 parts of water-based emulsion, 20 parts of damping filler, 10 parts of organic filler, 10 parts of crosslinking agent, 2 parts of catalyst, 5 parts of water;

[0047] Gas blowing agent is CO 2 Gas, the temperature of the gas blowing agent is 250°C, and the pressure of the gas blowing agent is 8Mpa.

[0048] Preferably, the aqueous emulsion is a mixture of epoxy resin emulsion and polyurethane resin emulsion, wherein both the epoxy resin and the polyurethane resin have a glass transition temperature of 40°C to 60°C.

[0049] Preferably, the damping filler is calcium carbonate.

[0050] Preferably, the organic filler is a defoamer, a levelin...

Embodiment 3

[0060] A micro-foaming water-based damping coating, which uses water-based emulsion as the main agent, damping fillers as the main filler, organic fillers as auxiliary fillers, and an appropriate amount of crosslinking agent, catalyst, gas foaming agent and water;

[0061] Contains the following raw materials in parts by weight:

[0062] 35 parts of aqueous emulsion, 50 parts of damping filler, 5 parts of organic filler, 30 parts of crosslinking agent, 1 part of catalyst, and 17 parts of water.

[0063] Gas blowing agent is CO 2 Gas, the temperature of the gas blowing agent is 235°C, and the pressure of the gas blowing agent is 9Mpa.

[0064] Preferably, the aqueous emulsion is a mixed solution of an alkyd resin emulsion and an epoxy resin emulsion, wherein the glass transition temperatures of the alkyd resin and the epoxy resin are both 70°C to 80°C.

[0065] Preferably, the damping filler is barium sulfate and titanium dioxide glass fiber.

[0066] Preferably, the organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com