Method for polymerizing reverse atom transfer radicals under activation action of alkali on halohydrocarbon

A technology of atom transfer and polymerization method, which is applied in the field of new controllable free radical polymerization, can solve the problems of high price and environmental pollution, and achieve the effect of reducing reaction cost, reducing raw material cost, and solving expensive raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] After the purification of methyl methacrylate monomer, ethyl 2-bromoisobutyrate halogenated hydrocarbon and sodium phosphate, the preparation of polymerization reaction components, methyl methacrylate, ethyl 2-bromoisobutyrate, bromide The molar ratio of iron (high valence transition metal catalyst) to sodium phosphate is 200:1:1:2. The preparation process is as follows: 0.0836 grams of ferric bromide and 0.0928 grams of sodium phosphate are weighed in the glove box and put into an eggplant-shaped bottle, and 6 milliliters of methyl methacrylate monomer is added into the eggplant-shaped bottle, and after magnetic stirring for 20 minutes, Then 37.7 microliters of ethyl 2-bromoisobutyrate was added, and stirring was continued for 2 minutes to obtain a pre-reaction mixture.

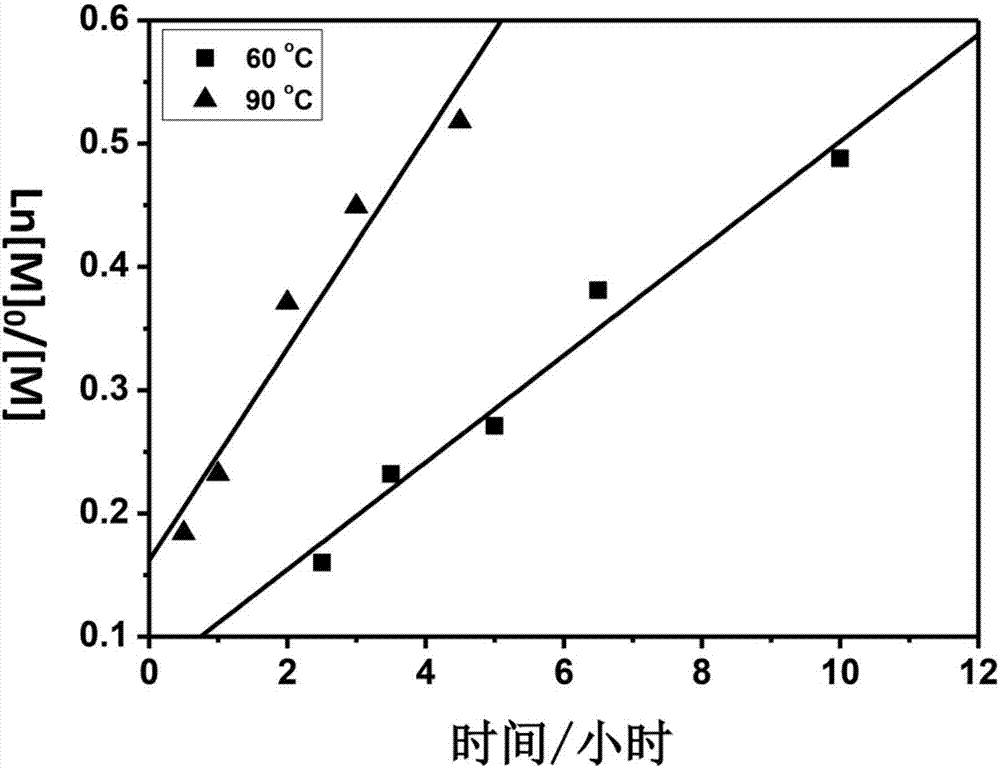

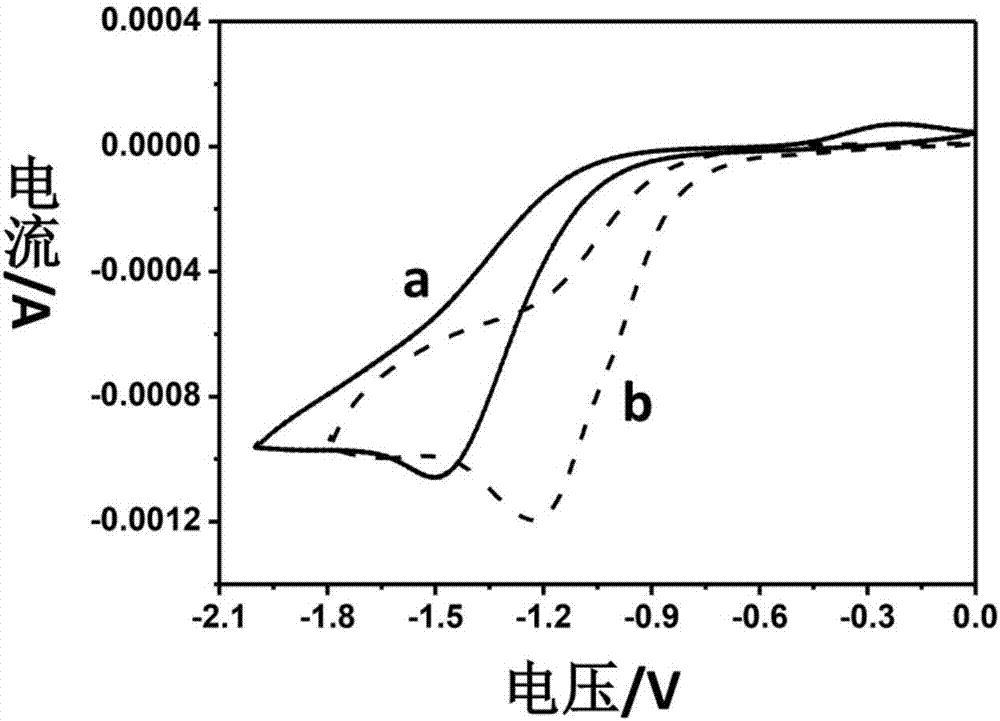

[0048] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C; after the polymerization reaction reaches the predetermined ...

Embodiment 2

[0050] After purification of methyl methacrylate monomer, ethyl 2-bromophenylacetate, halogenated hydrocarbon, and sodium hydroxide, the polymerization reaction components are prepared, methyl methacrylate, ethyl 2-bromophenylacetate, bromine The molar ratio of ferric oxide (high valence state transition metal catalyst) to sodium hydroxide is 200:1:1:2. The preparation process is: weigh 0.0836 grams of ferric bromide and 0.032 grams of sodium hydroxide in the glove box and put them into an eggplant-shaped bottle, add 6 milliliters of methyl methacrylate monomer into the eggplant-shaped bottle, and stir magnetically for 20 minutes. , and then added 49.5 microliters of ethyl 2-bromophenylacetate, and continued to stir for 2 minutes to obtain a pre-reaction mixture.

[0051] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C and 90°C respectively; after the polymerization reaction reaches the predete...

Embodiment 3

[0054] After purification of methyl methacrylate monomer, ethyl 2-bromophenylacetate halogenated hydrocarbon and sodium carbonate, the preparation of polymerization reaction components, methyl methacrylate, ethyl 2-bromophenylacetate, bromide The molar ratio of iron (high valence transition metal catalyst) to sodium carbonate is 200:1:1:4. The preparation process is as follows: in the glove box, 0.0836 grams of ferric bromide and 0.120 grams of sodium carbonate are weighed and put into an eggplant-shaped bottle, and 6 milliliters of methyl methacrylate monomer is added into the eggplant-shaped bottle, and after magnetic stirring for 20 minutes, Then 49.5 microliters of ethyl 2-bromophenylacetate was added, and stirring was continued for 2 minutes to obtain a pre-reaction mixture.

[0055] Transfer the pre-reaction mixture in the eggplant-shaped bottle to the heating device, and control the reaction temperature to 60°C. After the polymerization reaction reaches the predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com