Method and device for extracting ultrapure lithium carbonate from industrial-grade lithium carbonate

A lithium carbonate, ultra-purity technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of complicated steps, low efficiency, low lithium utilization rate, etc., to reduce production costs, high purity of finished products, High utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

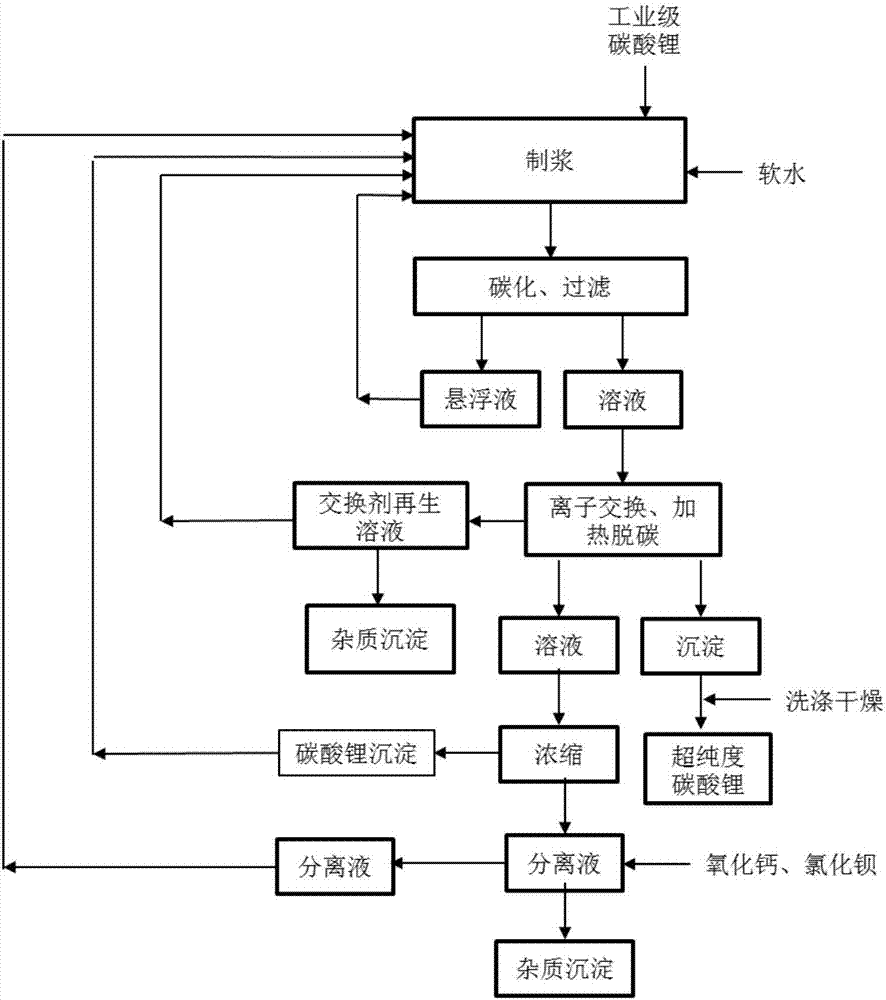

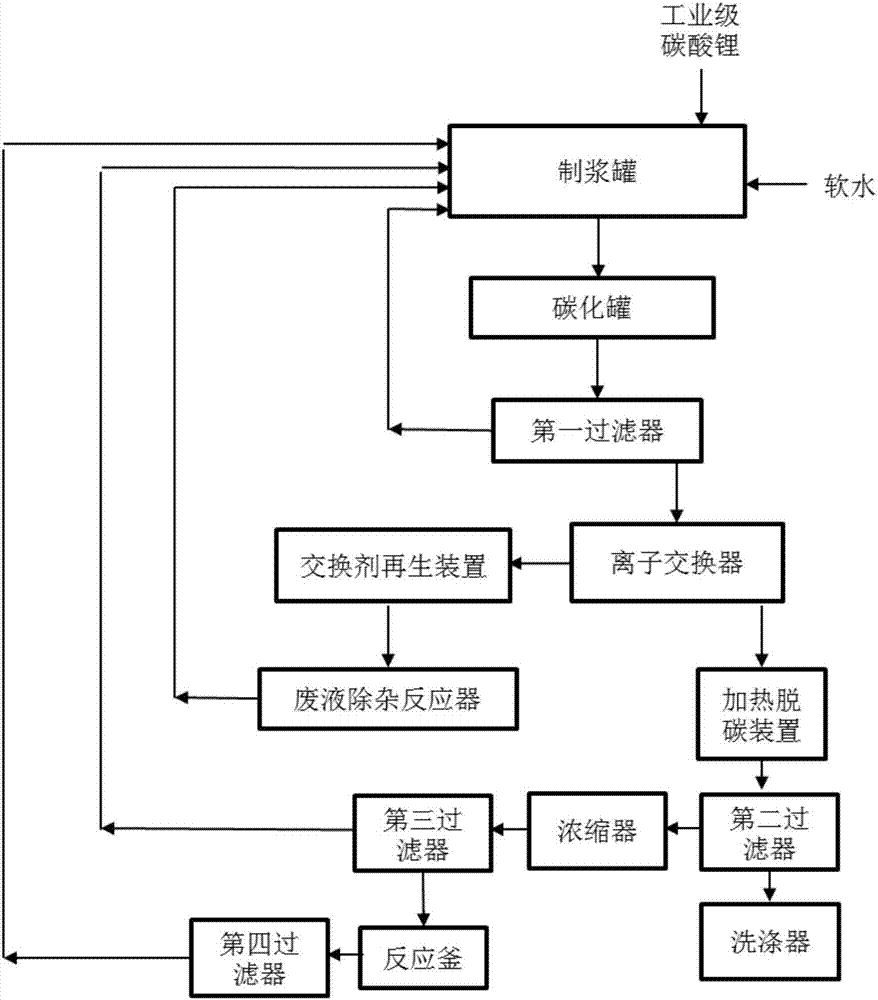

[0032] The present invention is further described below in conjunction with accompanying drawing:

[0033] Ultra-purity lithium carbonate is extracted from industrial-grade lithium carbonate. Ultra-purity lithium carbonate means that the content of lithium carbonate exceeds 99.99%. Industrial grade lithium carbonate is mixed with different impurities according to different origins. This patent processes industrial grade lithium carbonate mainly containing calcium, magnesium, potassium, sodium, boron and sulfate. Lithium carbonate is slightly soluble in water, and lithium bicarbonate is highly soluble in water. Lithium carbonate is carbonized to generate lithium bicarbonate, and then calcium and magnesium ions are removed by ion exchange, and lithium bicarbonate is decarburized by heating. Sodium dissolves in water, so the precipitated lithium carbonate after decarburization will be extremely pure.

[0034] In the traditional process, similar processes for preparing ultra-pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com