Light multi-rotor unmanned aerial vehicle frame carrier type take-off and landing platform

A multi-rotor unmanned, take-off and landing platform technology, applied in the direction of aircraft landers, etc., can solve the problems of difficult to find reliable take-off and landing points, difficulty in aircraft patrol operations, increased labor intensity, etc., to achieve convenient and fast loading and unloading, light weight, and labor-saving The effect of intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

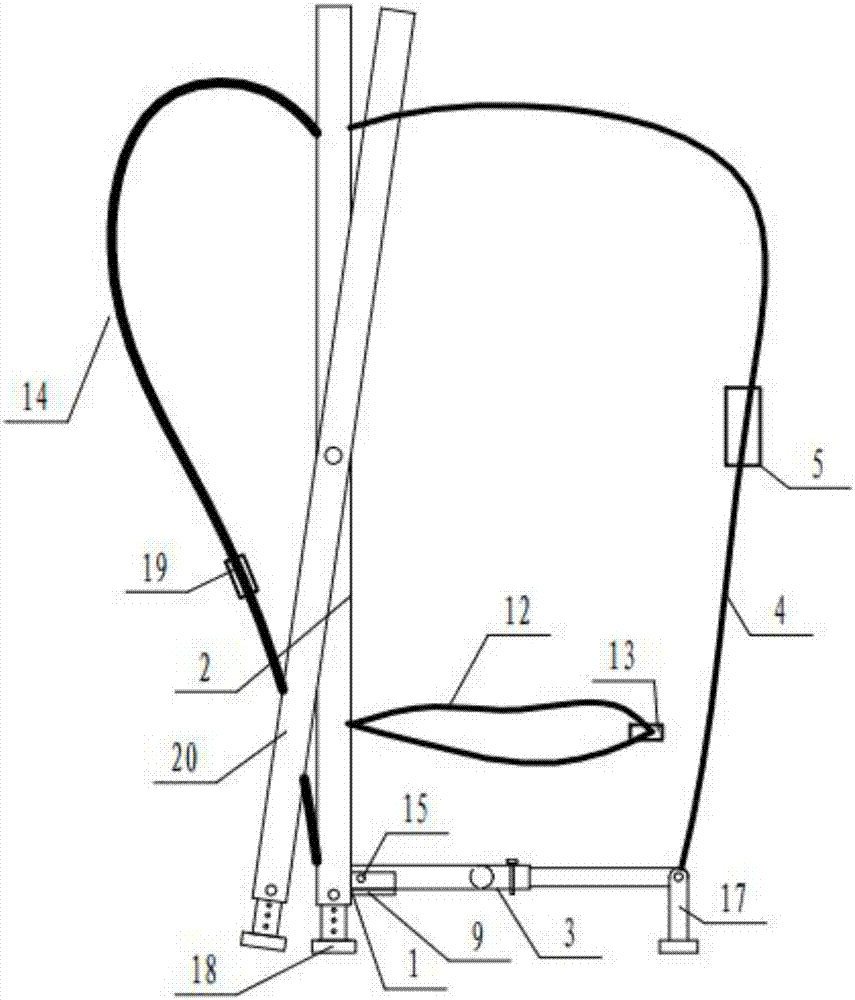

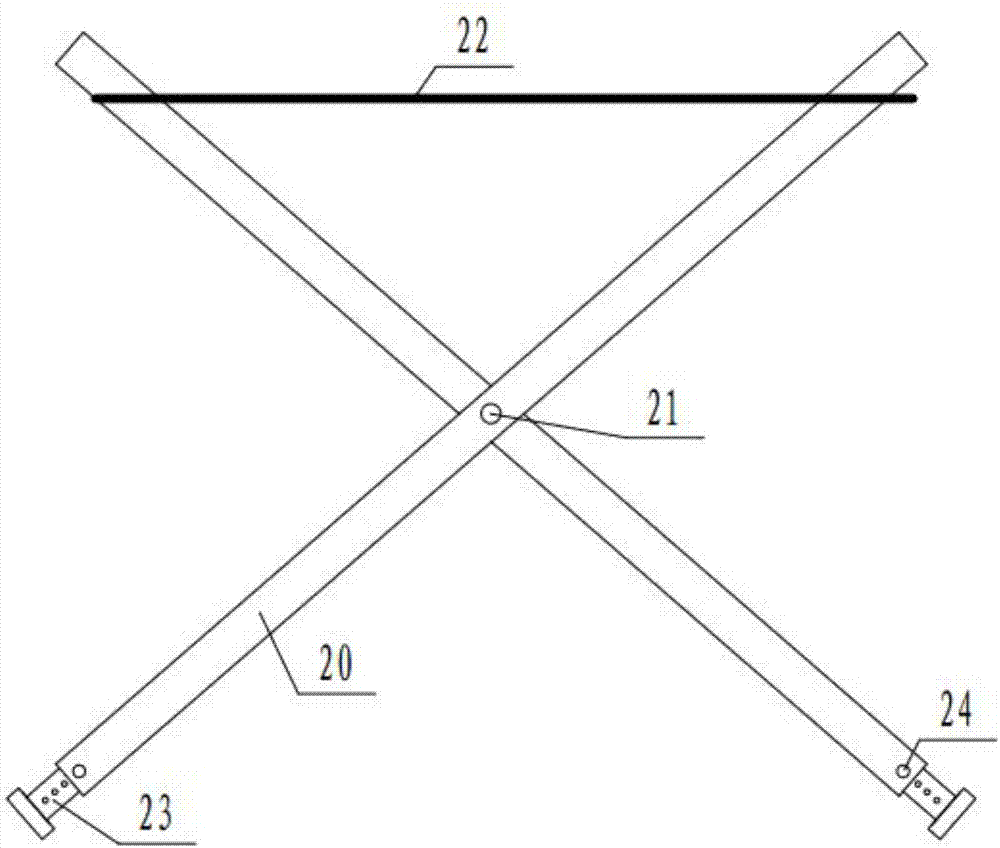

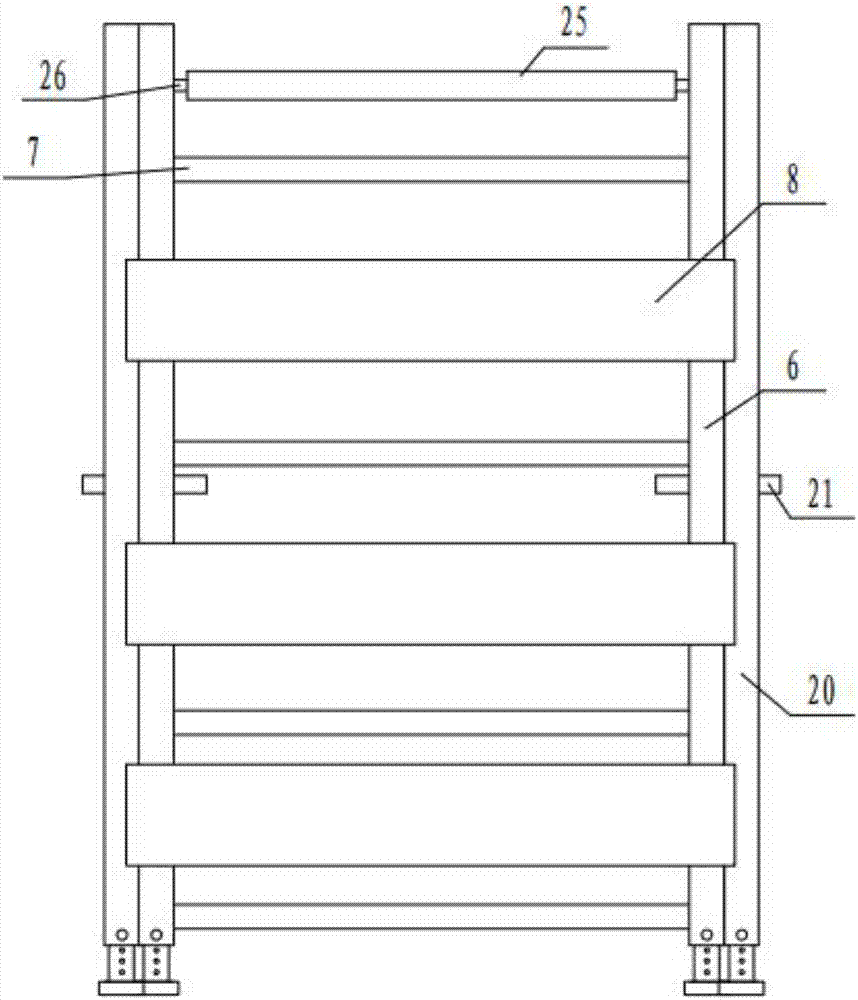

[0021] Example: such as Figure 1-Figure 5 As shown, a light multi-rotor unmanned aerial vehicle back-frame take-off and landing platform includes an L-shaped frame 1, the L-shaped frame 1 includes a front frame 2 and a bottom frame 3, the front end of the bottom frame 3 is connected to the lower end of the front frame 2, and the front frame 2 The front side is provided with double straps 14, and the rear end of the bottom frame 3 is fixedly connected with two wrapping straps 4, and the other end of the two wrapping straps 4 is connected to the upper end of the front frame 2 after bypassing the drone. Symmetrically rotatable two rotating rods 20 of equal height, the two rotating rods 20 rotate around the rotating shaft 21 and intersect with the front frame frame 2, and a detachable fabric made of high-strength fabric is arranged on the front frame 2 upper end and the two rotating rods 20 upper ends. The canvas 22 and the double straps 14 are provided with a strap lock 19, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com