Deburring device for cast steel joint

A cast steel joint and deburring technology, which is applied to machine tools, grinders, and metal processing equipment suitable for grinding workpiece edges, can solve problems such as low safety factor and low grinding efficiency, and achieve fast wear and save grinding costs , The effect of saving the use of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

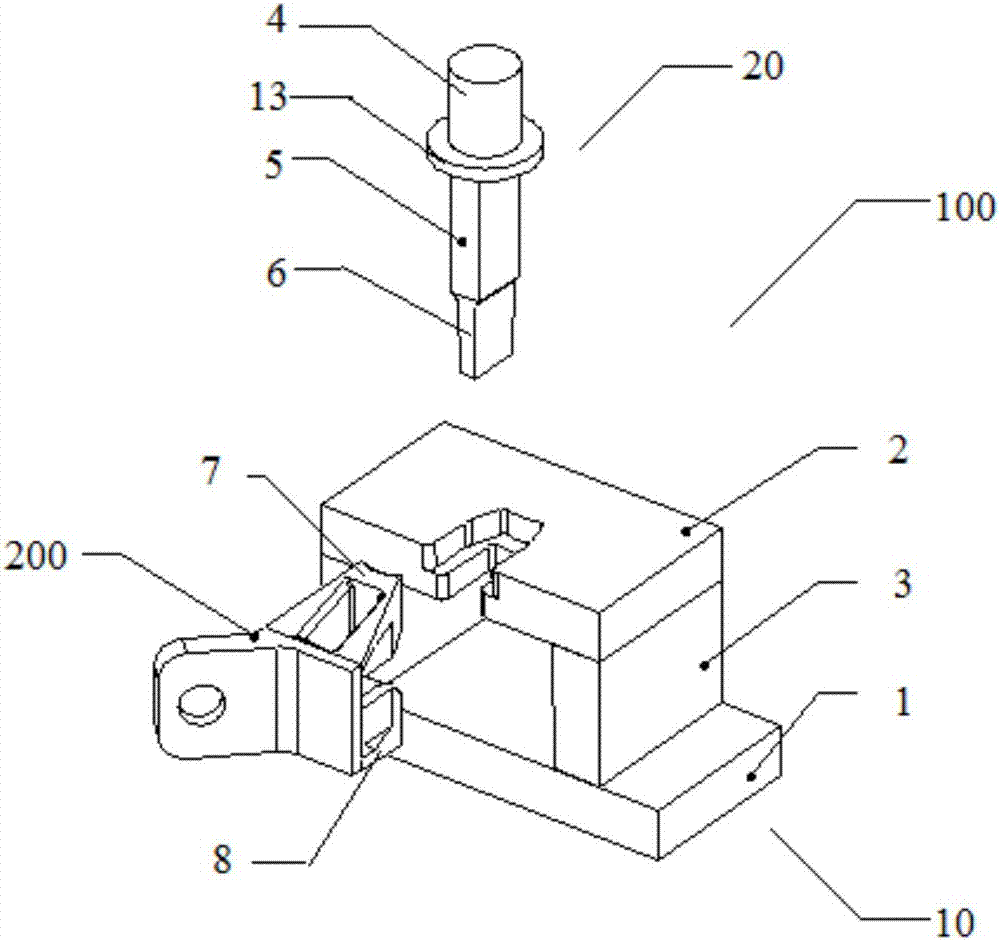

[0028] Such as figure 1 Shown is a schematic view of the state of the deburring device 100 and the cast steel joint 200 to be deburred according to a preferred embodiment of the present invention before work. The deburring device 100 mainly includes two parts: a positioning mechanism 10 and a punching mechanism 20, wherein the positioning mechanism 10 is used to fix the cast steel joint 200, and mainly includes: a base 1, a plate portion 2, a support column 3, and a punching mechanism 20 It is arranged above the positioning mechanism 10 and is used for punching the burrs on the cast steel joint 200 .

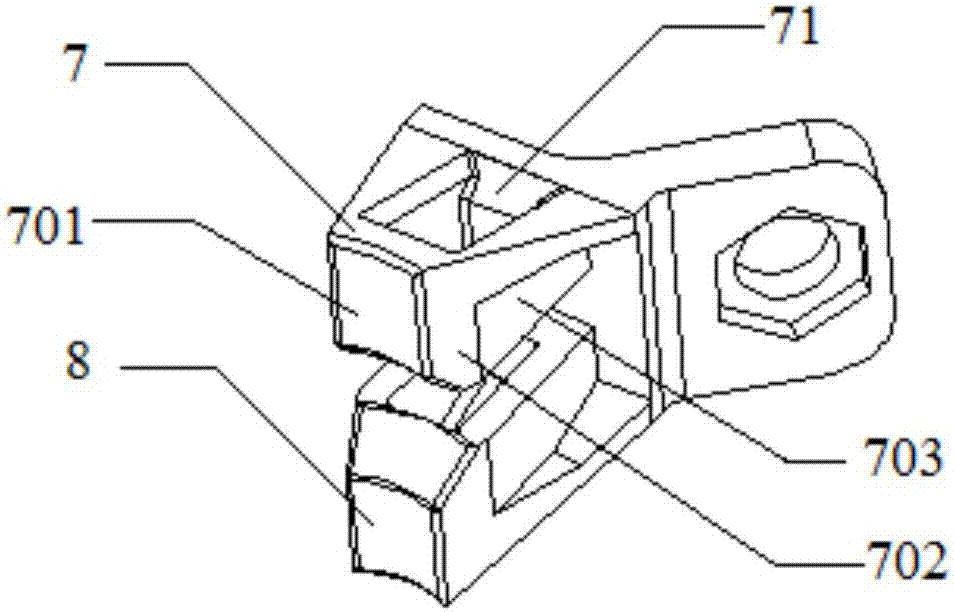

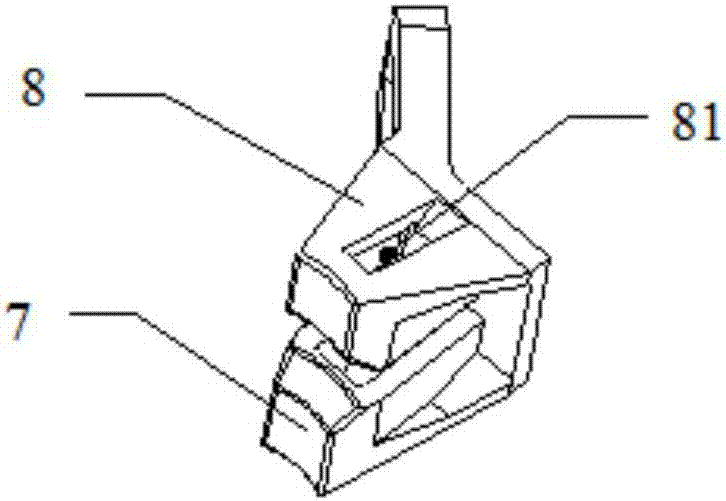

[0029] Specifically, as Figure 2A , Figure 2B As shown, the cast steel joint 200 includes a first head 7 and a second head 8 that are vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com