Roll bending forming method for aircraft skin

A technology for aircraft skin and roll forming, applied in aircraft parts, vehicle parts, transportation and packaging, etc., can solve the problems of poor thickness, inconsistent deformation and curvature of parts, etc., to improve production efficiency, avoid parts defects, and improve safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

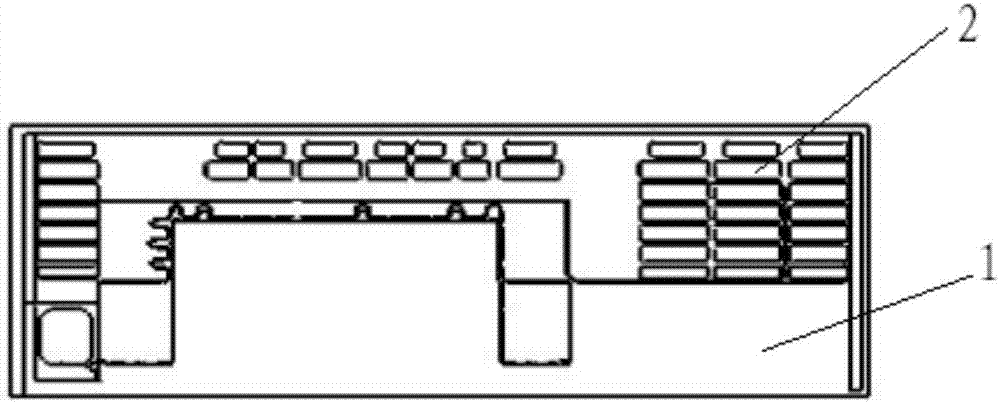

[0019] Referring to the accompanying drawings, the embodiment takes the skin of a certain type of aircraft as an example. The material of the skin is 2060-T8E30 aluminum-lithium alloy, and its external dimensions are δ6mm×1100mm×6010mm. The skin is a variable thickness part, and its thickness distribution is δ6.0, δ5.0, δ3.5, δ2.8, δ1.4. Adopt the method of the present invention to carry out roll bending processing to it:

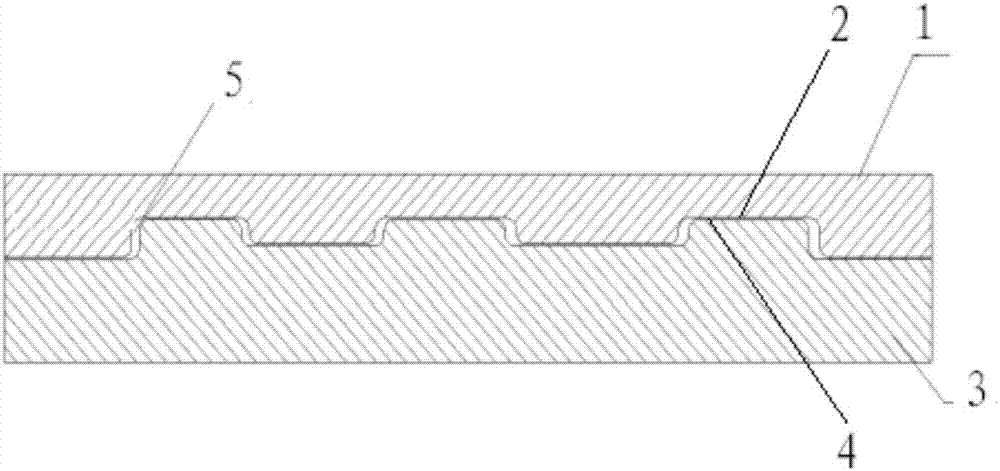

[0020] First, according to the theoretical model of aircraft skin, the plate-shaped skin material is milled by machine milling method. According to its thickness distribution, the sunken area forms a concave surface 2. At this time, the skin 1 is a concave surface. Flat state of profile 2;

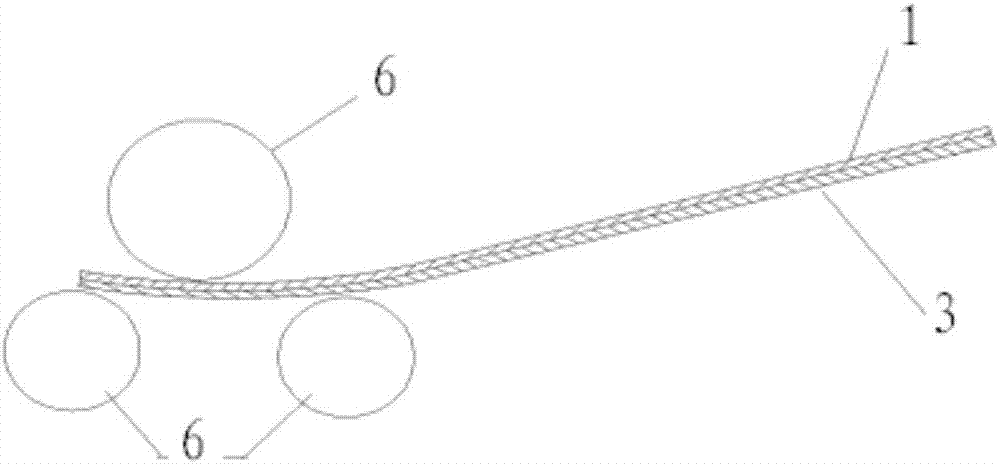

[0021] Secondly, choose a plastic polyurethane composite board with a thickness of δ6 mm as the filling board 3. According to the theoretical model of the aircraft skin, the filling board is milled and cut by the method of machining and milling in reverse. The milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com